Product Description

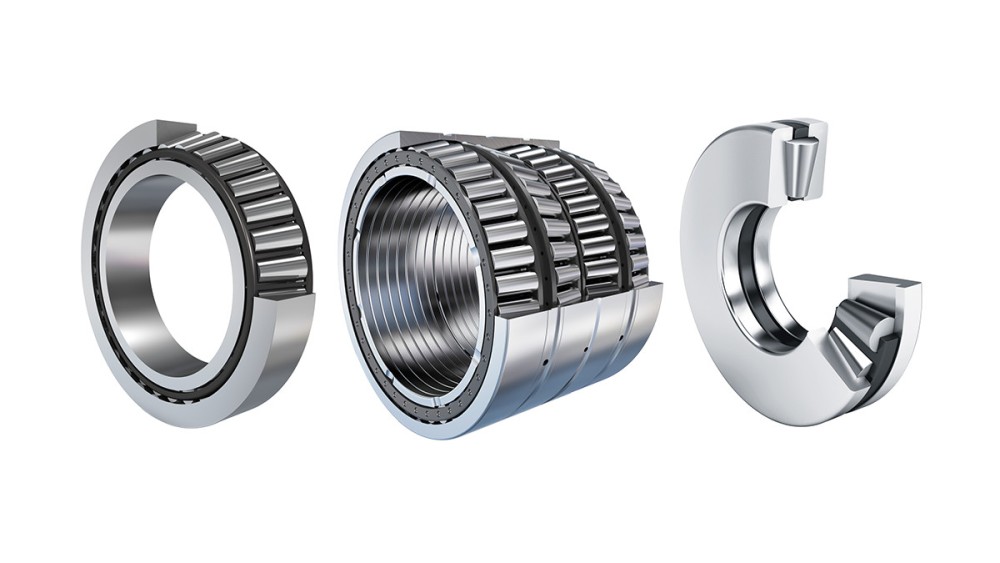

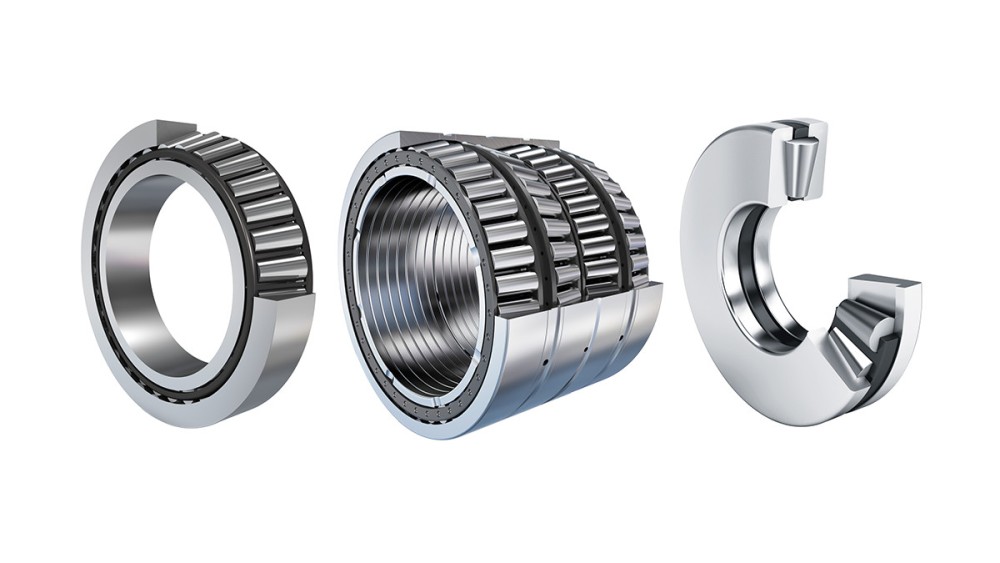

ZKLDF100 Axial angular contact ball bearing Introduction:

ZKLDF100 Axial angular contact ball bearing are axial and radial combined cylindrical roller bearings, which is fixed by a bidirectional thrust bearing and a centripetal-guided bearing. They can support radial loads, axial loads from both directions and tilting moments free from clearance. For the convenienience of transportation and fixing,two or 3 symmetrical screws are fastened to the 2 rings in oder to prevent rollers and rings generating collisions which influence bearing accuracy.

ZKLDF100 Axial angular contact ball bearing Display:

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Rolling Body: | Roller Bearings |

|---|---|

| The Number of Rows: | Single |

| Outer Dimension: | Medium and Large(120-190mm) |

| Material: | Bearing Steel |

| Spherical: | Non-Aligning Bearings |

| Load Direction: | Axial Bearing |

| Samples: |

US$ 180/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do rolling contact bearings perform in high-speed or high-load applications?

Rolling contact bearings are designed to perform effectively in high-speed and high-load applications. Their specific design features and characteristics allow them to withstand the demands and challenges associated with these conditions. Here’s a detailed explanation of how rolling contact bearings perform in high-speed or high-load applications:

- High-Speed Performance:

Rolling contact bearings are well-suited for high-speed applications due to their low friction characteristics. The rolling motion between the rolling elements and the raceways minimizes friction and heat generation, enabling smooth rotation at high speeds. The design of rolling contact bearings, including the selection of suitable materials and precision manufacturing, ensures the balance between load-carrying capacity and reduced friction at high speeds. As a result, these bearings can operate efficiently and reliably in applications such as electric motors, machine tools, turbochargers, and aerospace systems that require rapid and precise rotational motion.

- High-Load Capacity:

Rolling contact bearings are engineered to handle high loads and distribute them effectively. The rolling elements in the bearings, such as balls or rollers, distribute the applied loads over a larger contact area, reducing stress concentrations and preventing premature failure. The materials used in rolling contact bearings, such as high-grade steels and specialized alloys, provide the necessary strength and durability to withstand heavy loads. Additionally, the design of the bearing, including the number and size of the rolling elements, the geometry of the raceways, and the cage construction, is optimized to maximize load-carrying capacity. This enables rolling contact bearings to perform reliably in high-load applications, including heavy machinery, automotive drivetrains, construction equipment, and industrial processes.

- Lubrication for High-Speed and High-Load Conditions:

Lubrication is crucial for the performance of rolling contact bearings in high-speed or high-load applications. The lubricant helps reduce friction, dissipate heat, and prevent wear and damage to the bearing surfaces. For high-speed applications, specialized lubricants with low viscosity and high thermal stability are often used to ensure efficient lubrication and prevent excessive heat buildup. In high-load applications, lubrication plays a vital role in load distribution and reducing the risk of premature failure due to excessive stress. Proper lubrication selection and maintenance are essential to ensure optimal performance and longevity of rolling contact bearings under high-speed or high-load conditions.

- Preload and Stiffness:

In certain high-speed or high-load applications, rolling contact bearings may be preloaded to enhance their stiffness and improve their performance. Preload is a controlled axial force applied to the bearing that eliminates internal clearances and minimizes deflection under load. By applying preload, the rolling contact bearings can maintain their dimensional stability, minimize vibration, and enhance their ability to handle high-speed or high-load conditions. Preload is commonly utilized in precision machine tools, spindle bearings, and other applications where rotational accuracy and rigidity are critical.

In summary, rolling contact bearings perform exceptionally well in high-speed or high-load applications. They are designed to minimize friction, handle heavy loads, and maintain operational integrity under demanding conditions. Through their low friction characteristics, high-load capacity, appropriate lubrication, and potential use of preload, rolling contact bearings ensure reliable and efficient operation in various industries and applications requiring high-speed or high-load capabilities.

Can you provide guidance on the selection and sizing of rolling contact bearings for specific applications?

Yes, I can provide guidance on the selection and sizing of rolling contact bearings for specific applications. Choosing the right rolling contact bearings involves considering various factors such as load requirements, operating conditions, speed, and environmental factors. Here’s a detailed explanation of the steps involved in selecting and sizing rolling contact bearings:

- Identify Application Requirements:

Start by identifying the specific requirements of your application. Consider factors such as the type and magnitude of the loads the bearing will be subjected to, the operating speed, and any special environmental conditions like temperature, moisture, or exposure to corrosive substances. Understanding these requirements is crucial as it forms the basis for selecting the appropriate rolling contact bearing.

- Analyze Load Conditions:

Next, analyze the load conditions acting on the bearing. Determine if the load is radial, axial, or a combination of both. Consider factors such as the magnitude, direction, and frequency of the load. This analysis helps in determining the appropriate bearing type, such as deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings, or tapered roller bearings, that can handle the specific load conditions effectively.

- Calculate Equivalent Load:

Calculate the equivalent load acting on the bearing. In cases where the load acting on the bearing is a combination of radial and axial loads, it is necessary to calculate the equivalent load. The equivalent load accounts for the differing effects of radial and axial loads on the bearing and helps in determining the required bearing size and capacity.

- Consider Speed and Operating Conditions:

Take into account the speed at which the bearing will operate and the specific operating conditions. Higher speeds may require bearings with special design features or materials to handle the increased centrifugal forces and temperature rise. Consider factors such as lubrication requirements, temperature limits, and any special considerations for factors like shock loads, vibrations, or misalignment. These factors influence the selection of appropriate bearing types and configurations.

- Consult Bearing Manufacturer’s Catalogs:

Refer to the catalogs or technical specifications provided by bearing manufacturers. These catalogs contain detailed information about various bearing types, sizes, load ratings, and performance characteristics. Use the information provided to narrow down the options based on your application requirements and load calculations.

- Verify Bearing Life:

Check the calculated bearing life to ensure it meets the required operational lifespan of your application. Bearing manufacturers provide life calculation formulas based on industry standards such as ISO or ABMA. These formulas take into account factors like load, speed, and reliability requirements to estimate the expected bearing life. Verify that the selected bearing will provide the desired operational lifespan under the given operating conditions.

- Consider Mounting and Dismounting:

Lastly, consider the ease of mounting and dismounting the bearing in your specific application. Evaluate factors such as the bearing’s fit tolerance, the required clearance or preload, and any special mounting or dismounting procedures. Ensure that the selected bearing can be easily installed and maintained in your application.

It is important to note that the selection and sizing of rolling contact bearings can be complex, and it is advisable to seek the assistance of bearing manufacturers, engineers, or experts in the field to ensure the optimal selection for your specific application.

Can you describe the load-carrying capacity and load ratings of rolling contact bearings?

Rolling contact bearings are designed to carry various types of loads in mechanical systems. The load-carrying capacity and load ratings of rolling contact bearings play a crucial role in determining their suitability for specific applications. Here’s a detailed explanation of these concepts:

- Load-Carrying Capacity:

The load-carrying capacity of a rolling contact bearing refers to its ability to support and distribute loads without excessive deformation or failure. It is influenced by factors such as the bearing’s design, material properties, and operating conditions. Rolling contact bearings are primarily designed to carry two types of loads:

- Radial Loads: Radial loads act perpendicular to the axis of rotation and are supported by the bearing’s raceways. Radial loads can arise from the weight of the shaft, centrifugal forces, or external forces applied to the bearing. The load-carrying capacity for radial loads is typically specified by the maximum radial load the bearing can withstand without suffering permanent deformation or reduced performance.

- Axial Loads: Axial loads act parallel to the axis of rotation and are supported by the bearing’s configuration, such as the arrangement of the rolling elements or the presence of thrust surfaces. Axial loads can arise from forces that push or pull along the axis of rotation. The load-carrying capacity for axial loads is typically specified by the maximum axial load the bearing can withstand without experiencing excessive wear or reduced performance.

It’s important to note that the load-carrying capacity of a rolling contact bearing is influenced by factors such as rotational speed, lubrication, temperature, and operating conditions. These factors can affect the performance and durability of the bearing under different load conditions.

- Load Ratings:

Load ratings provide standardized values that indicate the maximum permissible loads a rolling contact bearing can carry under specific operating conditions. These ratings help engineers and designers select bearings that can withstand the expected loads in a given application. The two primary load ratings specified for rolling contact bearings are:

- Dynamic Load Rating: The dynamic load rating (C) represents the maximum load that a bearing can carry for a specified number of revolutions or operating hours without developing excessive wear or fatigue. It is based on the bearing’s ability to withstand rolling contact fatigue, which is the most common mode of failure in rolling contact bearings. The dynamic load rating is typically provided by the bearing manufacturer and is expressed in units of force (such as Newtons or pounds-force).

- Static Load Rating: The static load rating (Co) indicates the maximum load that a bearing can withstand without permanent deformation when the bearing is stationary or subjected to very slow rotational speeds. It represents the load capacity of the bearing under static or slowly changing loads. Similar to the dynamic load rating, the static load rating is also provided by the bearing manufacturer and expressed in units of force.

It’s important to consider both the dynamic and static load ratings when selecting a rolling contact bearing for an application. The dynamic load rating is crucial for assessing the bearing’s ability to withstand the varying loads during operation, while the static load rating provides information about the bearing’s resistance to deformation under stationary or slow-speed conditions.

By considering the load-carrying capacity and load ratings of rolling contact bearings, engineers can choose the appropriate bearing type and size to ensure reliable and efficient operation in their specific applications.

editor by CX 2024-04-26

China factory High Load Hot Sale Angular Contact Ball Bearing 7016AC 7016acm 71816c double row ball bearing

Product Description

Product Parameters

| Bearing type | Boundary Dimensions( mm ) | Speed Rating(ipm) | Load Rating(kn) | Weight(kg) | ||||

| d | D | B | Grease lubrication | Oil lubrication | Dynamic Cr | Static Cor | ||

| 7000AC | 10 | 26 | 8 | 22000 | 30000 | 4.55 | 1.97 | 0.019 |

| 7001AC | 12 | 28 | 8 | 20000 | 26000 | 5.1 | 2.38 | 0.571 |

| 7002AC | 15 | 32 | 9 | 19000 | 24000 | 5.58 | 2.85 | 0.03 |

| 7003AC | 17 | 35 | 10 | 17000 | 21000 | 6 | 3.25 | 0.04 |

| 7004AC | 20 | 42 | 12 | 16000 | 19000 | 9.38 | 5.02 | 0.069 |

| 7005AC | 25 | 47 | 12 | 15000 | 18000 | 10.1 | 5.85 | 0.08 |

| 7006AC | 30 | 55 | 13 | 13000 | 15000 | 13.2 | 8.3 | 0.116 |

| 7007AC | 35 | 62 | 14 | 11000 | 13000 | 16 | 10.3 | 0.155 |

| 7008AC | 40 | 68 | 15 | 9000 | 11000 | 17 | 11.8 | 0.185 |

| 7009AC | 45 | 75 | 16 | 8000 | 10000 | 21 | 14.8 | 0.23 |

| 7571AC | 50 | 80 | 16 | 7000 | 9000 | 22.05 | 16.21 | 0.25 |

| 7011AC | 55 | 90 | 18 | 7000 | 8500 | 30.2 | 21.8 | 0.362 |

| 7012AC | 60 | 95 | 18 | 6300 | 7500 | 31.65 | 24.22 | 0.385 |

| 7013AC | 65 | 100 | 18 | 6000 | 7000 | 32 | 24.72 | 0.41 |

| 7014AC | 70 | 110 | 20 | 5000 | 6700 | 38.5 | 30.5 | 0.575 |

| 7015AC | 75 | 115 | 20 | 5300 | 6300 | 40.2 | 33.2 | 0.603 |

| 7016AC | 80 | 125 | 22 | 5000 | 6000 | 47.5 | 39.8 | 0.821 |

| 7017AC | 85 | 130 | 22 | 4500 | 5600 | 50.8 | 42.8 | 0.848 |

| 7018AC | 90 | 140 | 24 | 4300 | 5300 | 58 | 49.8 | 1.1 |

| 7019AC | 95 | 145 | 24 | 4000 | 5000 | 57.8 | 50 | 1.15 |

| 7571AC | 100 | 150 | 24 | 3800 | 4800 | 64.5 | 56.2 | 1.18 |

| 7571AC | 110 | 170 | 28 | 3400 | 4300 | 81.8 | 72.8 | 1.89 |

| 7571AC | 120 | 180 | 28 | 3000 | 3800 | 87.5 | 79.2 | 1.99 |

| 7026AC | 130 | 200 | 33 | 2800 | 3600 | 105 | 96.8 | 3.08 |

| 7571AC | 140 | 210 | 33 | 2400 | 3200 | 116 | 108 | 3.17 |

| 7030AC | 150 | 225 | 35 | 2200 | 3000 | 132 | 125 | 3.9 |

| 7032AC | 160 | 240 | 38 | 2000 | 2800 | 145 | 138 | 4.83 |

| 7034AC | 170 | 260 | 42 | 1900 | 2600 | 170 | 170 | 6.5 |

| 7036AC | 180 | 280 | 46 | 1300 | 2400 | 188 | 198 | 8.51 |

| Model | Model | Model | Model | Model | Model | Model | Model | Model | Model | Model | Model |

| 7000AC | 7212AC | 7408AC | 7048ACM | 7308ACM | 71801C | 71912C | QJ212M | 7201BTN | 7224BM | 7305BM | 7408BM |

| 7001AC | 7213AC | 7409AC | 7309ACM | 71802C | 71913C | QJ213M | 7202BTN | 7226BM | 7306BM | 7409BM | |

| 7002AC | 7214AC | 7410AC | 7200ACM | 7310ACM | 71803C | 71914C | QJ214M | 7203BTN | 7228BM | 7307BM | 7410BM |

| 7003AC | 7215AC | 7411AC | 7201ACM | 7311ACM | 71804C | 71915C | QJ215M | 7204BTN | 7230BM | 7308BM | 7412M |

| 7004AC | 7216AC | 7412AC | 7202ACM | 7312ACM | 71805C | 71916C | QJ216M | 7205BTN | 7232BM | 7309BM | 7413BM |

| 7005AC | 7217AC | 7413AC | 7203ACM | 7313ACM | 71806C | 71917C | QJ217M | 7206BTN | 7234BM | 7310BM | 7414BM |

| 7006AC | 7218AC | 7414AC | 7204ACM | 7314ACM | 71807C | 71918C | QJ218M | 7207BTN | 7236BM | 7311BM | 7416BM |

| 7007AC | 7219AC | 7415AC | 7205ACM | 7315ACM | 71808C | 71919C | QJ219M | 7208BTN | 7238BM | 7312BM | 7432BM |

| 7008AC | 7220AC | 7416AC | 7206ACM | 7316ACM | 71809C | 71920C | QJ220M | 7209BTN | 7240BM | 7313BM | |

| 7009AC | 7221AC | 7207ACM | 7317ACM | 71810C | 71921C | QJ222M | 7210BTN | 7244BM | 7314BM | ||

| 7571AC | 7222AC | 7000ACM | 7208ACM | 7318ACM | 71811C | 71922C | QJ224M | 7211BTN | 7248BM | 7315BM | |

| 7011AC | 7224AC | 7001ACM | 7209ACm | 7319AC | 71812C | 71924C | QJ226M | 7212BTN | 7252 BM | 7316BM | |

| 7012AC | 7226AC | 7002ACM | 7210ACM | 7320ACM | 71813C | 71926C | QJ228M | 7213BTN | 7256BM | 7317BM | |

| 7013AC | 7228AC | 7003ACM | 7211ACM | 7321ACM | 71814C | 71928C | QJ230M | 7214BTN | 7260BM | 7319BM | |

| 7014AC | 7230AC | 7004ACM | 7212ACM | 7322ACM | 71815C | 71930C | QJ232M | 7215BTN | 7264BM | 7320BM | |

| 7015AC | 7005ACM | 7213ACM | 7324ACM | 71816C | 71932C | QJ234M | 7216BTN | 7322BM | |||

| 7016AC | 7301AC | 7006ACM | 7214ACM | 7326ACM | 71817C | 71934C | QJ236M | 7217BTN | 7324BM | ||

| 7017AC | 7302AC | 7007ACM | 7215ACM | 7328ACM | 71818C | 71936C | QJ240M | 7218BTN | 7326BM | ||

| 7018AC | 7303AC | 7008ACM | 7216ACM | 7330ACM | 71819C | 71938C | QJ244M | 7301BTN | 7328BM | ||

| 7019AC | 7304AC | 7009ACM | 7217ACM | 7332ACM | 71820C | 71940C | 7219BTN | 7302BTN | 7330BM | ||

| 7571AC | 7305AC | 7571ACM | 7218ACM | 7334ACM | 71821C | 7220BTN | 7332BM | ||||

| 7571AC | 7306AC | 7011ACM | 7219ACM | 7336ACM | 71822C | QJ1018M | QJ305M | 7222BTN | 7304BTN | 7334BM | |

| 7571AC | 7307AC | 7012ACM | 7220ACM | 7340ACM | 71824C | QJ1571M | QJ306M | 7224BTN | 7305BTN | 7336BM | |

| 7571AC | 7308AC | 7013ACM | 7221ACM | 71826C | QJ1571M | QJ307M | 7226BTN | 7306BTN | 7338BM | ||

| 7026AC | 7309AC | 7014ACM | 7222ACM | 71828C | QJ1571M | QJ308M | 7307BTN | 7340BM | |||

| 7571AC | 7310AC | 7015ACM | 7224ACM | 7405ACM | 71830C | QJ1026M | QJ309M | 7308BTN | 7344BM | ||

| 7030AC | 7311AC | 7016ACM | 7226ACM | 7406ACM | 71832C | QJ1571M | QJ310M | 7309BTN | 7318BM | ||

| 7032AC | 7312AC | 7017ACM | 7228ACM | 7407ACM | 71834C | QJ1030M | QJ311M | 7206BM | 7310BTN | 7356BM | |

| 7034AC | 7313AC | 7018ACM | 7230ACM | 7408ACM | 71836C | QJ1032M | QJ312M | 7207BM | 7311BTN | ||

| 7036AC | 7314AC | 7019ACM | 7232ACM | 7409ACM | 71838C | QJ1034M | QJ313M | 7208BM | 7312BTN | ||

| 7315AC | 7571ACM | 7234ACM | 7410ACM | 71840C | QJ1036M | QJ314M | 7209BM | 7313BTN | |||

| 7200AC | 7316AC | 7571ACM | 7236ACM | 7411ACM | QJ1038M | QJ315M | 7210BM | 7314BTN | |||

| 7201AC | 7317AC | 7571ACM | 7238ACM | 7412ACM | 71901C | QJ1040M | QJ316M | 7211BM | 7315BTN | ||

| 7202AC | 7318AC | 7571ACM | 7240ACM | 7413ACM | 71902C | QJ1044M | QJ317M | 7212BM | 7316BTN | ||

| 7203AC | 7319AC | 7026ACM | 7244ACM | 7414ACM | 71903C | QJ1048M | QJ318M | 7213BM | 7317BTN | ||

| 7204AC | 7320AC | 7571ACM | 7415A0M | 71904C | QJ319M | 7214BM | 7318BTN | ||||

| 7205AC | 7321AC | 7030ACM | 7301ACM | 7416ACM | 71905C | QJ205M | QJ320M | 7215BM | 7319BTN | ||

| 7206AC | 7322AC | 7032ACM | 7302ACM | 7417ACM | 71906C | QJ206M | QJ322M | 7216BM | 7320BTN | ||

| 7207AC | 7324AC | 7034ACM | 7303ACM | 7418ACM | 71907C | QJ207M | QJ324M | 7217BM | 7322BTN | ||

| 7208AC | 7036ACM | 7304A0M | 7420ACM | 71908C | QJ208M | QJ326M | 7218BM | ||||

| 7209AC | 7405AC | 7038ACM | 7305ACM | 7432ACM | 71909C | QJ209M | QJ328M | 7219BM | |||

| 7210AC | 7406AC | 7040ACM | 7306ACM | 71910C | QJ210M | QJ330M | 7220BM | ||||

| 7211AC | 7407AC | 7044ACM | 7307ACM | 71911C | QJ211M | QJ336M | 7222BM |

Our business:Produce and customize various bearing brands. (Packaging and logo can be customized. All copyright belongs to the customer. We promise not to disclose any information.)

We can supply a wide range of Auto bearings. The bearings are widely applicable to themost of cars in the world.

Detailed Photos

Packaging & Shipping

Company Profile

HangZhou Haver Seiko Bearing Co.,Ltd. is a high-end Automotive bearing manufacturer from ZheJiang China. Its headquarters is located in HangZhou,ZheJiang Province.HangZhou Haver Seiko Bearing Co.,Ltd. Exports 80% of its auto parts,covering more than 40% countries in Europe,the Middle East,Southeast Asia, and South America.

As a high-end brand in the automotive bearing manufacturing industry, HangZhou Haver Seiko Bearing Co.,Ltd. has more than 20 years of experience in automotive design and manufacturing,and can meet the most stringent requirements of customers.

Exhibitions&Partners

FAQ

Q:Are you trading company or manufacturer?

–We are the company dealing in trading business and manufacturing business.

Q:What’s the MOQ?

–MOQ is 2pcs for standardized products; 300pcs for customized products. There is no MOQ for sample orders.

Q:How long is the lead time?

–The lead time for sample orders is 1-3 days, for bulk orders is generally in 3-15 days.The delivery time is generally in 2 days after payment. It’s according to the order amount.

Q:Do you offer free samples?

–If you place an order, we can return part of sample fee even all of fee to you. It also depends on the quantity of order and the type of sample. And you just need to pay freight.

Q: Could you customized for me?

–Sure,we can supply OEM service as per your drawing or samples.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 25° |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the potential challenges or limitations associated with using rolling contact bearings in various industries?

Rolling contact bearings offer numerous benefits and are widely used in various industries. However, there are certain challenges and limitations associated with their use. It is important to understand these potential issues to ensure proper application and mitigate any adverse effects. Here’s a detailed explanation of the challenges and limitations associated with using rolling contact bearings:

- Load Capacity:

While rolling contact bearings are designed to handle substantial loads, there are limitations to their load capacity. Exceeding the specified load limits can lead to premature wear, increased friction, and potentially catastrophic failure. It is crucial to consider the expected loads in the application and select bearings with appropriate load ratings and configurations. In some high-load applications, alternative bearing types, such as spherical roller bearings or tapered roller bearings, may be more suitable to handle the specific load requirements.

- Speed Limitations:

Rolling contact bearings have speed limitations that need to be considered in high-speed applications. At high rotational speeds, centrifugal forces can affect the performance and reliability of rolling contact bearings. The limitation is primarily due to factors such as the bearing’s internal clearance, cage design, lubrication, and the potential for increased heat generation. To overcome speed limitations, specialized high-speed bearings with improved designs and materials, such as ceramic balls or hybrid bearings, may be used in certain applications.

- Maintenance and Lubrication:

Proper maintenance and lubrication are essential for the reliable operation of rolling contact bearings. Inadequate lubrication or improper maintenance practices can result in increased friction, heat buildup, and premature wear. It is important to follow the manufacturer’s recommendations for lubrication intervals, lubricant selection, and application methods. In some applications, such as high-temperature environments or extreme operating conditions, special considerations may be required to ensure effective lubrication and prevent bearing failure.

- Environmental Factors:

Rolling contact bearings can be sensitive to certain environmental factors. Exposure to contaminants, such as dirt, dust, moisture, or aggressive chemicals, can lead to accelerated wear and corrosion. In industries where the operating environment is harsh or contaminated, additional protective measures, such as sealing arrangements or the use of specialized coatings, may be necessary to enhance the bearing’s resistance to environmental factors. It is important to evaluate the specific environmental conditions and select bearings that are suitable for the intended application.

- Installation and Alignment:

Improper installation or misalignment of rolling contact bearings can result in reduced performance and premature failure. Achieving accurate alignment and proper fitment during installation is crucial. Misalignment can lead to increased friction, uneven load distribution, and potential damage to the bearing surfaces. It is necessary to follow the manufacturer’s installation guidelines, use appropriate tools, and employ precision alignment techniques to ensure optimal performance and longevity of the bearings.

- Size and Space Constraints:

In some applications, size and space constraints may limit the use of rolling contact bearings. The available space for bearing installation may be limited, requiring the use of compact or specialized bearing designs. Additionally, certain applications may demand high load-carrying capacity within a restricted envelope, necessitating careful bearing selection and possibly the use of alternative bearing types. It is important to consider the space limitations and select bearings that can accommodate the specified requirements while fitting within the available space.

While rolling contact bearings offer numerous advantages, it is essential to be aware of the potential challenges and limitations associated with their use. By understanding these factors and taking appropriate measures, such as careful selection, proper maintenance, and adherence to installation guidelines, the performance and reliability of rolling contact bearings can be optimized in various industries and applications.

Are there specific considerations for choosing rolling contact bearings in applications with extreme operating conditions or high precision requirements?

When selecting rolling contact bearings for applications with extreme operating conditions or high precision requirements, there are specific considerations to take into account. Here’s a detailed explanation of these considerations:

- Operating Conditions:

In applications with extreme operating conditions, such as high temperatures, high speeds, or corrosive environments, special attention must be given to the bearing’s ability to withstand these conditions. Considerations include:

- Temperature: High-temperature applications require bearings with heat-resistant materials and lubricants designed to withstand elevated temperatures without degradation. Specialized heat treatment processes may be necessary to enhance the bearing’s ability to handle thermal expansion and avoid premature failure.

- Speed: High-speed applications demand bearings that can operate at significantly higher rotational speeds without excessive friction, heat generation, or loss of precision. Factors such as cage design, lubrication, and material selection play a crucial role in achieving reliable performance at high speeds.

- Corrosion and Chemical Resistance: In corrosive environments or applications exposed to chemicals, bearings with corrosion-resistant materials, such as stainless steel or ceramic, and appropriate sealing mechanisms are essential to prevent premature failure due to chemical attack or rust formation.

- Vibration and Shock: Applications subject to high vibration or shock loads require bearings capable of withstanding these dynamic forces. Special designs, such as extra internal clearance or improved cage stability, may be necessary to ensure reliable operation under such conditions.

- Precision Requirements:

In applications with high precision requirements, such as precision instruments, machine tools, or optical equipment, specific considerations are essential to meet the desired level of accuracy and repeatability. Some key factors include:

- Tolerance and Dimensional Stability: Bearings used in high-precision applications must have strict dimensional tolerances and excellent dimensional stability to ensure precise positioning and alignment. This requires careful control during the manufacturing process and the use of high-quality materials.

- Runout and Radial Clearance: Runout, which refers to the deviation from perfect circularity, and radial clearance, which affects the internal play between the rolling elements and the raceways, must be tightly controlled to achieve the desired precision. Bearings with low runout and minimal radial clearance are preferred for high-precision applications.

- Noise and Vibration: High-precision applications often require low noise and vibration levels. Bearings with optimized designs, such as improved cage stability, precision-ground raceways, and high-quality lubrication, help minimize noise and vibrations, ensuring accurate and quiet operation.

- Lubrication: Proper lubrication is crucial for high-precision bearings to reduce friction, minimize wear, and maintain consistent performance. Lubricants with low viscosity, high stability, and excellent temperature characteristics are typically used in precision applications.

Choosing the right rolling contact bearings for applications with extreme operating conditions or high precision requirements requires careful consideration of factors such as temperature, speed, corrosion resistance, dimensional stability, and lubrication. Consulting with bearing manufacturers or experts can provide valuable guidance in selecting the most suitable bearings to meet the specific application’s demands.

What are rolling contact bearings, and how are they utilized in mechanical systems?

Rolling contact bearings are mechanical components used to facilitate smooth and efficient motion between two or more parts in a mechanical system. They utilize rolling elements, such as balls or rollers, to minimize friction and enable relative motion between the rotating or moving parts. Here’s a detailed explanation of rolling contact bearings and their utilization in mechanical systems:

- Definition and Construction:

Rolling contact bearings consist of an inner ring, an outer ring, rolling elements (balls or rollers), and a cage or retainer that holds the rolling elements in position. The inner and outer rings have raceways, which are carefully machined surfaces that guide the rolling elements. The rolling elements roll between the raceways, reducing friction and enabling smooth rotation or linear motion.

- Types of Rolling Contact Bearings:

There are various types of rolling contact bearings, including:

- Ball Bearings: These bearings use spherical balls as rolling elements and are suitable for applications with light to moderate loads and high-speed requirements. Ball bearings are commonly used in motors, fans, household appliances, and automotive applications.

- Roller Bearings: Roller bearings use cylindrical or tapered rollers as rolling elements. They can handle higher loads and provide better shock absorption than ball bearings. Roller bearings are often found in heavy machinery, construction equipment, and industrial applications.

- Needle Bearings: Needle bearings are a type of roller bearing with long, thin rollers. They have a high load capacity and are used in applications where space is limited and high radial load support is required.

- Thrust Bearings: Thrust bearings are designed to support axial loads and allow for rotational or linear motion in the axial direction. They are commonly used in automotive transmissions, machine tools, and thrust applications.

- Tapered Roller Bearings: Tapered roller bearings have conical rollers and are designed to handle both radial and axial loads. They are commonly used in wheel bearings, gearboxes, and heavy-duty applications.

- Utilization in Mechanical Systems:

Rolling contact bearings are utilized in various mechanical systems for several reasons:

- Reduced Friction: By utilizing rolling elements, rolling contact bearings minimize friction compared to sliding contact bearings. This reduces energy losses, heat generation, and wear, resulting in improved efficiency and extended service life of the mechanical system.

- Smooth Motion: Rolling contact bearings enable smooth and controlled motion between components. They allow for low-friction rotation or linear movement, providing precise and reliable operation in a wide range of applications.

- Load Distribution: Rolling contact bearings distribute loads evenly across their contact surfaces, reducing stress concentrations and preventing premature wear or failure. This enables mechanical systems to handle various loads and forces without compromising performance.

- Positional Accuracy: Rolling contact bearings help maintain accurate positioning of components in mechanical systems, ensuring alignment and reducing the risk of misalignment-related issues. This is crucial in precision machinery, robotics, and other applications where positional accuracy is essential.

- Versatility: Rolling contact bearings are available in different sizes, configurations, and materials to suit a wide range of applications. They can accommodate different load capacities, speeds, and environmental conditions, making them adaptable and versatile in various mechanical systems.

In summary, rolling contact bearings are essential components in mechanical systems. They utilize rolling elements to minimize friction, enable smooth motion, distribute loads, and provide positional accuracy. By utilizing rolling contact bearings, mechanical systems can achieve efficient and reliable operation in a wide range of applications, from small appliances to heavy machinery and industrial equipment.

editor by CX 2024-04-11

China manufacturer Auto Parts Ball Bearing Metal Bearing High Load High Speed 1316 Self-Aligning Ball Bearings wholesaler

Item Description

All complex details as belows:

Material data:

Other Relevant

FAQ:

1. Are you a factory or a trading organization?

We are a expert manufacture of deep groove ball bearings and other bearings.

two. Is OEM available?

Yes, OEM is accessible. We have skilled designer to assist your model promotion.

3. Is the sample obtainable?

Yes, samples are accessible for you to examination the good quality.

4. Have the products been tested just before transport?

Indeed, all of our bearings have been examined prior to supply.

five. How long is your shipping time?

As described over, there are different types of shipping for your purchase. We make positive to deliver merchandise as soon as all merchandise are created and tested.

six. What is your terms of payment ?

You can pay out by T/T, L/C, and so forth., and it can be negotiated in accordance to various orders with various amount.

eight.How to stock and maintenance my bearings?

Do not shop bearings right on concrete floors, where drinking water can condense and gather on the bearing

Retailer the bearings on a pallet or shelf, in an location exactly where the bearings will not be subjected to higher humidityor extreme temperature that might result in condensation forming

Components Utilized in Bearings

If you are not familiar with the kinds of bearings, you may possibly be intrigued in being aware of more about the supplies utilized to manufacture them. Here is a look at what each sort of bearing is manufactured of, how it is utilized, and how a lot they price. To uncover the proper bearing for your application, it is critical to pick a good quality lubricant. The components used in bearings are determined by their type and applications. Selecting the appropriate lubricant will extend its existence, and protect your machine’s elements from harm and untimely put on.

Resources employed in bearings

Bearings are made from a selection of resources. Stainless metal is a frequent material used for the elements of bearings. It has a increased content of chromium and nickel. When uncovered to oxygen, chromium reacts with it to form chromium oxide, which gives a passive film. For increased temperatures, teflon and Viton are also employed. These resources supply outstanding corrosion resistance and are typically preferred by companies for their unique homes.

Stainless metal is another content utilized in bearings. AISI 440C is a large-carbon stainless steel typically utilized in rolling-speak to bearings. It is broadly utilized in corrosive environments, specially in applications exactly where corrosion resistance is more crucial than load capability. It can also be warmth-handled and hardened to 60 HRC, but has reduced fatigue daily life than SAE 52100. Stainless steel bearings could carry a twenty-forty% value high quality, but their excellent overall performance is really worth the added income.

Graphite and molybdenum disulfide are two of the most common materials utilised in bearings. While graphite is a common content in bearings, it has quite very poor corrosion resistance and is unsuitable for apps in which oil or grease is required. Graphite-primarily based composite supplies are another choice. They merge the advantages of equally graphite and ceramic supplies. A range of proprietary supplies have been designed for substantial-temperature use, this sort of as graphite and MoS2.

Wood bearings have been close to for centuries. The oldest ones used wooden and Lignum Vitae. These materials ended up lightweight, but they ended up amazingly strong and sturdy. Wooden bearings have been also lubricated with animal fat. Throughout the 1700s, iron bearings have been a common option. In 1839, Isaac Babbitt invented an alloy containing difficult metal crystals suspended in a softer steel. It is regarded as a steel matrix composite.

Purposes of bearings

Bearings are used in a lot of various industries and methods to help facilitate rotation. The steel surfaces in the bearings assistance the excess weight of the load, which drives the rotation of the unit. Not all masses utilize the same sum of force to bearings, nevertheless. Thrust and radial masses act in distinctly various ways. To far better recognize the distinct uses of bearings, let us examine the various types of bearings. These flexible gadgets are important for a lot of industries, from cars to ships and from development to industrial procedures.

Cylindrical roller bearings are made to assistance weighty masses. Their cylindrical rolling aspect distributes the load over a greater area. They are not, nonetheless, suited to handling thrust hundreds. Needle bearings, on the other hand, use tiny diameter cylinders and can fit into tighter spaces. The positive aspects of these sorts of bearings are quite a few, and numerous leading producers are now leveraging the Industrial Net of Things (IIoT) to create linked intelligent bearings.

As a power generation business, bearings engage in an important part. From turbines to compressors, from generators to pumps, bearings are important elements of products. In addition to bearings, these parts aid shift the equipment, so they can work correctly. Usually, these factors use ball bearings, though some roller bearings are utilised as nicely. In addition to being productive and sturdy, these types of bearings also tend to be created to meet stringent inner clearance specifications and cage design and style requirements.

In addition to bearings for linear movement, bearings can also bear the excess weight of a rotary portion. Based on the software, they can be made to lessen friction amongst transferring areas. By constraining relative motion, bearings are utilised to minimize friction within a given application. The very best-created bearings decrease friction in a given application. If you are in the market for a new bearing, NRB Industrial Bearings Minimal is an exceptional source to get started your look for.

Varieties of bearings

The type of bearings you pick will have a considerable affect on the functionality of your equipment. Utilizing the correct bearings can improve performance, precision, and service intervals, and even reduce the price of getting and running equipment. There are a number of different kinds of bearings to choose from, such as ball bearings and flexure bearings. Some varieties use a fluid to lubricate their surfaces, while other individuals do not.

Plain bearings are the most typical kind of bearing, and are utilised for a range of purposes. Their cylindrical design makes it possible for for a relatively sleek motion. Typically created of copper or other copper alloy, they have minimal coefficients of friction and are commonly utilized in the development market. Some sorts of basic bearings are also available with a gudgeon pin, which connects a piston to a connecting rod in a diesel engine.

Magnetic bearings are the newest variety of bearing. They use long lasting magnets to produce a magnetic discipline all around the shaft with no necessitating any electrical power. These are tough to style, and are still in the early levels of advancement. Electromagnets, on the other hand, require no electricity but can perform very high-precision positioning. They can be very resilient and have a lengthy provider life. They are also light-weight and easy to repair.

Another variety of bearing is needle roller. These are made of slender, extended, and slender cylinders that are utilised in a range of purposes. Their slender measurement is perfect for a area-constrained application, and their small profile enables them to fit in tight locations. These varieties of bearings are typically employed in automotive applications, bar stools, and digicam panning units. They have a number of advantages over ball bearings, like the capacity to handle hefty axial loads.

Price of bearings

A extensive selection of variables influence the expense of aerospace bearings, which includes the bearing content and its volatility. Manufacturers usually use high-quality metal for aircraft bearings, which are extremely impacted by fluctuations in the metal value. Authorities policies also perform a part in the variation in trade value. The implementation of COVID-19 has modified the market dynamics, making an uncertain outlook for source and demand of aerospace bearings. New trade norms and transportation restrictions are expected to hamper the progress of this sector.

Demand from customers for aerospace bearings is mostly pushed by plane makers. In North The us, plane companies should satisfy very high expectations of excess weight, performance, and top quality. They also should be lightweight and expense-effective. This has resulted in a increasing price of aerospace bearings. The marketplace for aerospace bearings is anticipated to increase at the greatest CAGR more than the following few years, pushed by increasing investments in protection and aerospace infrastructure throughout Asia-Pacific.

Hub assemblies are also expensive. A wheel hub will cost between $four hundred and $five hundred for a single set of bearings. In addition to this, the pace sensor will be provided. The regular cost of wheel bearings is in between $400 and $500 for one particular aspect, such as labor. But this price tag range is much reduced if the bearing is a substitute of an total wheel assembly. It is still well worth noting that wheel hub bearings can be obtained independently for a reduce price tag.

Alternative of one particular or two wheel bearings will depend on the model and calendar year of the motor vehicle. For a little automobile, a single rear wheel bearing can expense amongst $a hundred ninety and $225, whereas two front wheel hubs can value upwards of $1,000. Labor and components prices will vary by spot, and labor charges might also be lined underneath some guarantee strategies. If you choose to have it carried out yourself, be certain to request a number of retailers for estimates.

Inspection of bearings

To sustain bearing performance and stop mishaps, periodic inspections are essential. In addition to ensuring reliability, these inspections improve productivity and efficiency. Standard maintenance includes disassembly inspection, replenishment of lubricant and checking procedure standing. Right here are some frequent methods to complete the needed inspections. Hold reading through to discover how to keep bearings. Soon after disassembly, you should clean the elements totally. Make sure that the bearings are free of charge of burrs, particles, and corrosion.

Ultrasound technologies is an superb resource for checking gradual-velocity bearings. Most ultrasound devices offer you extensive-ranging sensitivity and frequency tuning. Ultrasound can also be utilised to monitor bearing sound. Ultra-slow bearings are generally massive and greased with high-viscosity lubricant. Crackling sounds point out deformity. You can also hear for abnormal sounds by plugging a vibration analyzer into the equipment. Once the machine exhibits abnormal noise, schedule further inspections.

Ultrasonic inspection requires utilizing an ultrasound transducer to measure the amplitude of sound from a bearing. It is powerful in early warnings of bearing failure and stops in excess of-lubrication. Ultrasound inspection of bearings is a value-efficient solution for early analysis of bearing troubles. In addition to currently being a trustworthy instrument, ultrasonic testing is electronic and effortless to apply. The subsequent are some of the rewards of ultrasonic bearing inspection.

Dynamic high quality evaluation requires the use of a special fixture for measuring bearing deformations beneath low shaft speed and light radial load. The measurement of the fixture influences the value of the deformations. A fixture must be sized among the diameter of the sensor and the roller to guarantee greatest precision. The outer deformation sign is much more delicate with a bigger sensor diameter. A vibration-acceleration sensor is utilized for the distinction take a look at.