Product Description

Product Description

Angular contact ball bearing BA246-2A excavator bearing

Angular Contact Ball Bearing

1.High precision

2.Wide range of use

3.Open bearing

4.Competitive price

Angular contact ball bearings are CZPT to support radial load and axial load. As single row angular contact ball bearings can only support axial load in single direction, matched bearing mounting is often adopted to them. As matched pair of bearings, preload for them is more convenient. Retainer are made of brass, synthetic resins or others subject to individual bearing features and application conditions.

Angular contact ball bearing main purposes:

Single row angular contact ball bearings: machine tool spindles, high frequency motors, gas turbines, centrifuges, small car front, differential pinion shaft

Double row angular contact ball bearings: oil pump, Roots blower, air compressor, various types of transmission, fuel injection pumps, printing machine

Introduction:

Angular contact ball bearings have raceways in the inner and outer rings that are displaced with respect to each other in the direction of the bearing axis. This means that they are designed to accommodate combined loads, i.e. simultaneously acting radial and axial loads.

The axial load carrying capacity of angular contact ball bearings increases with increasing contact angle. The contact angle α is defined as the angle between the line joining the points of contact of the ball and the raceways in the radial plane, along which the load is transmitted from 1 raceway to another, and a line perpendicular to the bearing axis

Applications:

• Suitable for very high rotating speeds

•Well suited for medium high radial and axial loads in one or both directions

•Various seals and grease variants available for different operating conditions

•Numerous clearance and tolerance classes available for different operating conditions

•Application examples: electrical motors, general machinery, industrial gearboxes, pumps,agricultural machinery, etc.

high load capacity, super precision

Best supplier with competitive price

All brands

1:high precision Angular Contact Ball Bearings

1):Basic features:

– Simple design

– Inseparability

– Easiness of assembly

– High rates of rotation, especially for smaller and narrower series

– Possibility of radial and partial axial load transfers in both directions

2):Versions:

– With one or two side rubber seal RS, 2RS

– With reinforced one or two side rubber seal RSR, 2RSR

– With one or two side metal shields Z and ZZ (2Z)

– With snap ring groove in outer ring N

– With snap ring groove in outer ring and external snap ring NR

– In different radial clearances C5, C4, C3, C2

– In many combinations of above mentioned versions

2: Angular contact ball bearings description:

Basic Design:

Angular contact ball bearings are self retaining units which consist of solid inner and outer rings, and ball &cage assemblies.

The bearings have raceways in the inner and outer rings that are displaced with respect to each other in the direction of the bearing axis,

and are designed to accommodate combined loads, ie. simultaneously acting radial and axial loads.

Detailed Description:

Series :7000C,7200,7300C and so on

The axial load carrying capacity of angular contact ball bearings increases with increasing contact angle.

Types :single row angular contact ball bearing

Bearing Features:

Only axial loads in one direction for single row design

Axial loads in both directions for double row design and four-point contact design

Combined loads

High speed operations

Widespread use and versatility

3:Type of angular contact ball bearings

a=15 °7000C

a=25 °7000AC

a=40 °7000B

1) Single row angular contact ball bearing

2) Double row angular contact ball bearing

3) Four-point angular contact ball bearing

4:Advantages

Advantages of Angular Contact Ball Bearing:

1.Ultra clean steel to extend bearing life by up to 80%

2.Advanced grade technology

3.Quiet and smooth operation even at high speed

4.Super finished raceways

5.Offer products in 15,25 and 40 degree angles

6.Available in arrange of Polyamide, steel and brass cage assembles

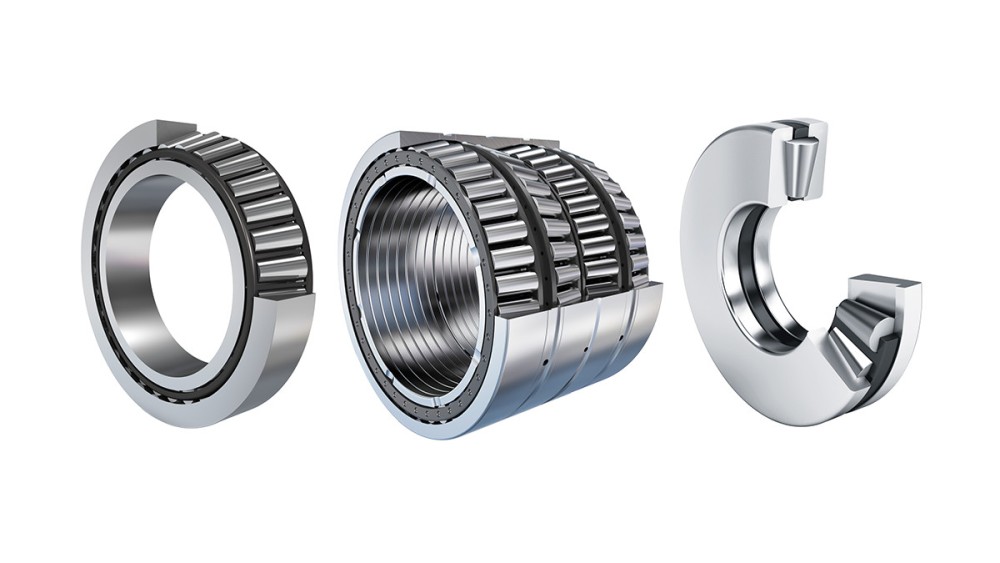

Detailed Photos

Related models

| d | D | B | |

| mm | mm | mm | |

| B7000-C-T-P4S | 10 | 26 | 8 |

| B7001-C-T-P4S | 12 | 28 | 8 |

| B7002-C-T-P4S | 15 | 32 | 9 |

| B7003-C-T-P4S | 17 | 35 | 10 |

| B7004-C-T-P4S | 20 | 42 | 12 |

| B7005-C-T-P4S | 25 | 47 | 12 |

| B7006-C-T-P4S | 30 | 55 | 13 |

| B7007-C-T-P4S | 35 | 62 | 14 |

| B7008-C-T-P4S | 40 | 68 | 15 |

| B7009-C-T-P4S | 45 | 75 | 16 |

| B7571-C-T-P4S | 50 | 80 | 16 |

| B7011-C-T-P4S | 55 | 90 | 18 |

| B7012-C-T-P4S | 60 | 95 | 18 |

| B7013-C-T-P4S | 65 | 100 | 18 |

| B7014-C-T-P4S | 70 | 110 | 20 |

| B7015-C-T-P4S | 75 | 115 | 20 |

| B7016-C-T-P4S | 80 | 125 | 22 |

| B7017-C-T-P4S | 85 | 130 | 22 |

| B7018-C-T-P4S | 90 | 140 | 24 |

| B7019-C-T-P4S | 95 | 145 | 24 |

| d | D | B | |

| mm | mm | mm | |

| B7571-C-T-P4S | 100 | 150 | 24 |

| B7571-C-T-P4S | 105 | 160 | 26 |

| B7571-C-T-P4S | 110 | 170 | 28 |

| B7571-C-T-P4S | 120 | 180 | 28 |

| B7026-C-T-P4S | 130 | 200 | 33 |

| B7571-C-T-P4S | 140 | 210 | 33 |

| B7030-C-T-P4S | 150 | 225 | 35 |

| B7032-C-T-P4S | 160 | 240 | 38 |

| B7034-C-T-P4S | 170 | 260 | 42 |

| B7036-C-T-P4S | 180 | 280 | 46 |

| B7038-C-T-P4S | 190 | 290 | 46 |

| B7040-C-T-P4S | 200 | 310 | 51 |

| B7044-C-T-P4S | 220 | 340 | 56 |

| B7048-C-T-P4S | 240 | 360 | 56 |

catalogue excavator bearing:

| Bearing Number | ID(mm) | OD(mm) | Height (For Install) |

| AC5033 | 250 | 330 | 37 |

| AC5836 | 289 | 355 | 34 |

| BA220-6WSA | 220 | 276 | 26 |

| AC4629 | 230 | 290 | 27 |

| AC4630 | 230 | 300 | 35 |

| AC4631 | 230 | 310 | 38 |

| AC4639 | 230 | 300 | 35 |

| AC4531 | 225 | 315 | 36 |

| AC463240 | 230 | 320 | 40 |

| AC423040 | 210 | 300 | 40 |

| AC6037 | 300 | 370 | 33 |

| AC523438-1 | 260 | 340 | 38 |

| BA240-3WSA | 240 | 310 | 32 |

| BA240-5WSA | 240 | 308 | 30 |

| BA222-1WSA | 222 | 273 | 26 |

| BA220-1 | 220 | 280 | 28 |

| BN220-1 | 220 | 280 | 28 |

| SF4831VPX1 | 240 | 310 | 33.4 |

| SF4815VPX1 | 240 | 310 | 34 |

| SF4860VPX1 | 240 | 320 | 38 |

| 240BA3251 | 240 | 320 | 38 |

| SF4826VPX1 | 240 | 310 | 33 |

| SF4852VPX1 | 240 | 310 | 33 |

| B-SF4454VPX1 | 220 | 295 | 33 |

| SF4444VPX1 | 220 | 295 | 32 |

| SF6015VPX1 | 300 | 372 | 36 |

| SF4411VPX1 | 220 | 290 | 32.5 |

| SF4615PX1 | 230 | 300 | 35 |

| SF4460PX1 | 220 | 300 | 35 |

| SF4903/246-1 | 246 | 308 | 32 |

| CR2256 | 110 | 150 | 22 |

| CR4411 | 220 | 290 | 33.5 |

| CR6016 | 300 | 380 | 39 |

| SF3235VPX1 | 160 | 200 | 20 |

| SF5235VPX1 | 260 | 330 | 34.5 |

| SF3215 | 160 | 200 | 20 |

| SF3215 | 160 | 200 | 28 |

| SF4007VPX1 | 200 | 250 | 25 |

| SF4007VPX1 | 200 | 250 | 24 |

| 180BA-2256 | 180 | 225 | 21.5 |

| BA230-7 | 230 | 300 | 35 |

| BA180-4WSA | 180 | 250 | 33 |

| BA280-2SA | 280 | 370 | 40 |

| 280BA40GS | 280 | 400 | 47 |

| BA200-7B | 200 | 250 | 25 |

| BA300-4WSA | 300 | 395 | 52 |

| BA340-1 | 340 | 440 | 52 |

| BA345-1WSA | 345 | 470 | 52 |

| BA205-1 | 205 | 295 | 40 |

| BA290-3A | 290 | 380 | 40 |

| BA250-4A | 250 | 330 | 38 |

| BA246-1A | 246 | 308 | 32 |

| BA246-2A | 246 | 313 | 32 |

| SF4910PX1 | 243 | 312 | 33 |

| BA200-10 | 200 | 280 | 38 |

| BA300-5 | 300 | 380 | 40 |

| BA230-2 | 230 | 320 | 40 |

| BA260-3 | 260 | 340 | 38 |

| BA260-4 | 260 | 340 | 38 |

| SF5246PX1 | 260 | 340 | 38 |

| BA195-3A | 195 | 280 | 36.5 |

| BA16519A | 165 | 203 | 17 |

| BA289-1SA | 289 | 355 | 32.5 |

| BA270-3 | 270 | 350 | 38 |

| 184BA-2251 | 184 | 226 | 21.5 |

| 260BA35S2 | 260 | 355 | 44 |

| 120BA16 | 120 | 165 | 22 |

| 135BA16 | 135 | 175 | 22 |

| BA176-1 | 176 | 216 | 22 |

| 245BA35S1 | 245 | 355 | 44 |

| 250BA36S1 | 250 | 360 | 44 |

| 200BA27V | 200 | 272 | 33 |

| 240BA32S1 | 240 | 320 | 38 |

| 210BA29V | 210 | 295 | 35 |

| 180BN19W/BTB7936 | 180 | 250 | 33 |

| SA180 | 180 | 235 | 27 |

| 105BA14 | 105 | 144 | 14 |

| 220BA300 | 220 | 300 | 38 |

| 150BA182 | 150 | 182 | 16 |

| 151BA179 | 151 | 179 | 14 |

| SF2812VPX1 | 140 | 175 | 17.5 |

| SF2907VPX1 | 143 | 175 | 17 |

| SF2912PX1 | 145 | 200 | 20 |

| SF3607VPX1 | 180 | 225 | 21 |

| SF3227VPX1 | 160 | 200 | 20 |

| SF3240VPX1 | 160 | 200 | 20 |

| SF4019VPX1 | 200 | 260 | 30 |

| SF4205PX1 | 210 | 280 | 35 |

| SF4224PX1 | 210 | 280 | 35 |

| SF7938 | 190 | 260 | 33 |

| SF2912 | 145 | 200 | 27.5 |

| 310BN42-2 | 310 | 422 | 45 |

| HS5715 | 117 | 145 | 14 |

| HS5714 | 126 | 154 | 14 |

| HS5713 | 320 | 383 | 30 |

| Double Row | |||

| BD110-1 | 110 | 140 | 28 |

| BD140-1 | 140 | 180 | 34 |

| BD155-6A | 155 | 198 | 48 |

| BA165-6A | 165 | 210 | 22 |

| BD165-6A | 165 | 210 | 52 |

| BD175-6A | 175 | 220 | 41 |

| BD185-6A | 185 | 232 | 51 |

| BD130-16A | 130 | 166 | 34/41 |

| BD130-1 | 130 | 166 | 29.5/34 |

| BA130-1 | 130 | 166 | 18 |

| BA135-6A | 135 | 170 | 20 |

| Tapered Roller Bearings | |||

| LM739749/739710 | 196.85 | 257.175 | 39.688 |

| L540049/54571 | 196.85 | 254 | 28.575 |

| L540048/54571 | 200 | 254 | 28 |

| LL639249/639210 | 196.85 | 241.3 | 23.812 |

| LL641110/49 | 203 | 261 | 28 |

| 544090/544116 | 228.6 | 295.275 | 33.338 |

| 544091/544118 | 231.775 | 300.038 | 33.338 |

| LL225749/225710 | 127 | 165.895 | 18.257 |

| L327249/327210 | 133.35 | 177.008 | 25.4 |

| JP11049/10 | 110 | 160 | |

| JP14049/JP14571 | 140 | 195 | 29 |

| 4T-T7FC060 | 60 | 125 | 37 |

| 4T-T7FC065 | 65 | 130 | 37 |

| 4T-T2ED070 | 70 | 130 | 42 |

| 4T-T2ED045 | 45 | 95 | 37 |

| LL735449/10 | 177.875 | 215.875 | 20.5 |

Factory view

Contact information

Anna , 15628959925

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 15° |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

| Samples: |

US$ 1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Can rolling contact bearings be customized or modified to meet specific industrial requirements?

Yes, rolling contact bearings can be customized or modified to meet specific industrial requirements. Bearing manufacturers offer a range of customization options to tailor bearings to unique application needs. These customizations can include modifications in design, materials, dimensions, and performance characteristics. Here’s a detailed explanation of the customization possibilities for rolling contact bearings:

- Design Modifications:

Bearing manufacturers can modify the design of rolling contact bearings to suit specific industrial requirements. This can involve altering the internal geometry, such as ball or roller profiles, cage design, or the number and arrangement of rolling elements. Design modifications aim to optimize the bearing’s load-carrying capacity, speed capability, or resistance to specific operating conditions. By customizing the design, manufacturers can address unique challenges and enhance the performance of rolling contact bearings in specific applications.

- Material Selection:

Rolling contact bearings can be customized by choosing specific materials for their components. Material selection depends on factors such as load requirements, operating temperatures, corrosion resistance, and lubrication conditions. Bearing manufacturers offer a variety of materials for various components, including bearing rings, rolling elements, cages, and seals. For example, high-temperature applications may require bearing rings made of heat-resistant steel or ceramic rolling elements to withstand the elevated temperatures. By selecting appropriate materials, rolling contact bearings can be customized to optimize their performance and reliability in specific industrial environments.

- Dimensional Modifications:

Bearing dimensions can be customized to meet specific industrial requirements. This may involve adjusting the inner and outer ring diameters, bore and outer diameter tolerances, or overall bearing width. Dimensional modifications are particularly useful when retrofitting bearings into existing equipment with unique space constraints. Customized dimensional changes ensure proper fitment and compatibility with the surrounding components, enabling seamless integration of rolling contact bearings into the target application.

- Sealing and Lubrication:

Sealing arrangements and lubrication options can be customized for rolling contact bearings. The choice of seals and lubricants depends on the desired level of contamination protection, operating temperatures, and specific requirements of the application. Customized sealing arrangements can include various types of seals, such as contact seals, non-contact seals, or specialized labyrinth seals, to prevent the ingress of contaminants and retain lubrication. Lubrication customization can involve selecting different types of lubricants, additives, or applying specific lubrication methods to optimize the bearing’s performance and extend its service life in specific industrial settings.

- Specialized Coatings and Surface Treatments:

To enhance the performance and durability of rolling contact bearings, manufacturers offer specialized coatings and surface treatments. These modifications can include applying corrosion-resistant coatings, low-friction coatings, or protective surface treatments to improve wear resistance or reduce frictional losses. Specialized coatings and surface treatments can be customized to specific industrial requirements, providing enhanced performance, longer service life, and improved reliability in challenging operating conditions.

Customization options for rolling contact bearings ensure that they can be tailored to meet the specific needs of various industries and applications. By collaborating with bearing manufacturers and providing detailed application requirements, industrial users can benefit from customized bearings that offer optimized performance, increased reliability, and extended service life in their specific operating environments.

Can you provide guidance on the selection and sizing of rolling contact bearings for specific applications?

Yes, I can provide guidance on the selection and sizing of rolling contact bearings for specific applications. Choosing the right rolling contact bearings involves considering various factors such as load requirements, operating conditions, speed, and environmental factors. Here’s a detailed explanation of the steps involved in selecting and sizing rolling contact bearings:

- Identify Application Requirements:

Start by identifying the specific requirements of your application. Consider factors such as the type and magnitude of the loads the bearing will be subjected to, the operating speed, and any special environmental conditions like temperature, moisture, or exposure to corrosive substances. Understanding these requirements is crucial as it forms the basis for selecting the appropriate rolling contact bearing.

- Analyze Load Conditions:

Next, analyze the load conditions acting on the bearing. Determine if the load is radial, axial, or a combination of both. Consider factors such as the magnitude, direction, and frequency of the load. This analysis helps in determining the appropriate bearing type, such as deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings, or tapered roller bearings, that can handle the specific load conditions effectively.

- Calculate Equivalent Load:

Calculate the equivalent load acting on the bearing. In cases where the load acting on the bearing is a combination of radial and axial loads, it is necessary to calculate the equivalent load. The equivalent load accounts for the differing effects of radial and axial loads on the bearing and helps in determining the required bearing size and capacity.

- Consider Speed and Operating Conditions:

Take into account the speed at which the bearing will operate and the specific operating conditions. Higher speeds may require bearings with special design features or materials to handle the increased centrifugal forces and temperature rise. Consider factors such as lubrication requirements, temperature limits, and any special considerations for factors like shock loads, vibrations, or misalignment. These factors influence the selection of appropriate bearing types and configurations.

- Consult Bearing Manufacturer’s Catalogs:

Refer to the catalogs or technical specifications provided by bearing manufacturers. These catalogs contain detailed information about various bearing types, sizes, load ratings, and performance characteristics. Use the information provided to narrow down the options based on your application requirements and load calculations.

- Verify Bearing Life:

Check the calculated bearing life to ensure it meets the required operational lifespan of your application. Bearing manufacturers provide life calculation formulas based on industry standards such as ISO or ABMA. These formulas take into account factors like load, speed, and reliability requirements to estimate the expected bearing life. Verify that the selected bearing will provide the desired operational lifespan under the given operating conditions.

- Consider Mounting and Dismounting:

Lastly, consider the ease of mounting and dismounting the bearing in your specific application. Evaluate factors such as the bearing’s fit tolerance, the required clearance or preload, and any special mounting or dismounting procedures. Ensure that the selected bearing can be easily installed and maintained in your application.

It is important to note that the selection and sizing of rolling contact bearings can be complex, and it is advisable to seek the assistance of bearing manufacturers, engineers, or experts in the field to ensure the optimal selection for your specific application.

What are rolling contact bearings, and how are they utilized in mechanical systems?

Rolling contact bearings are mechanical components used to facilitate smooth and efficient motion between two or more parts in a mechanical system. They utilize rolling elements, such as balls or rollers, to minimize friction and enable relative motion between the rotating or moving parts. Here’s a detailed explanation of rolling contact bearings and their utilization in mechanical systems:

- Definition and Construction:

Rolling contact bearings consist of an inner ring, an outer ring, rolling elements (balls or rollers), and a cage or retainer that holds the rolling elements in position. The inner and outer rings have raceways, which are carefully machined surfaces that guide the rolling elements. The rolling elements roll between the raceways, reducing friction and enabling smooth rotation or linear motion.

- Types of Rolling Contact Bearings:

There are various types of rolling contact bearings, including:

- Ball Bearings: These bearings use spherical balls as rolling elements and are suitable for applications with light to moderate loads and high-speed requirements. Ball bearings are commonly used in motors, fans, household appliances, and automotive applications.

- Roller Bearings: Roller bearings use cylindrical or tapered rollers as rolling elements. They can handle higher loads and provide better shock absorption than ball bearings. Roller bearings are often found in heavy machinery, construction equipment, and industrial applications.

- Needle Bearings: Needle bearings are a type of roller bearing with long, thin rollers. They have a high load capacity and are used in applications where space is limited and high radial load support is required.

- Thrust Bearings: Thrust bearings are designed to support axial loads and allow for rotational or linear motion in the axial direction. They are commonly used in automotive transmissions, machine tools, and thrust applications.

- Tapered Roller Bearings: Tapered roller bearings have conical rollers and are designed to handle both radial and axial loads. They are commonly used in wheel bearings, gearboxes, and heavy-duty applications.

- Utilization in Mechanical Systems:

Rolling contact bearings are utilized in various mechanical systems for several reasons:

- Reduced Friction: By utilizing rolling elements, rolling contact bearings minimize friction compared to sliding contact bearings. This reduces energy losses, heat generation, and wear, resulting in improved efficiency and extended service life of the mechanical system.

- Smooth Motion: Rolling contact bearings enable smooth and controlled motion between components. They allow for low-friction rotation or linear movement, providing precise and reliable operation in a wide range of applications.

- Load Distribution: Rolling contact bearings distribute loads evenly across their contact surfaces, reducing stress concentrations and preventing premature wear or failure. This enables mechanical systems to handle various loads and forces without compromising performance.

- Positional Accuracy: Rolling contact bearings help maintain accurate positioning of components in mechanical systems, ensuring alignment and reducing the risk of misalignment-related issues. This is crucial in precision machinery, robotics, and other applications where positional accuracy is essential.

- Versatility: Rolling contact bearings are available in different sizes, configurations, and materials to suit a wide range of applications. They can accommodate different load capacities, speeds, and environmental conditions, making them adaptable and versatile in various mechanical systems.

In summary, rolling contact bearings are essential components in mechanical systems. They utilize rolling elements to minimize friction, enable smooth motion, distribute loads, and provide positional accuracy. By utilizing rolling contact bearings, mechanical systems can achieve efficient and reliable operation in a wide range of applications, from small appliances to heavy machinery and industrial equipment.

editor by CX 2024-04-26