Product Description

Slew Gear 061.20.571.100.11.1503 Four Point Contact Ball Bearing For JIB Crane

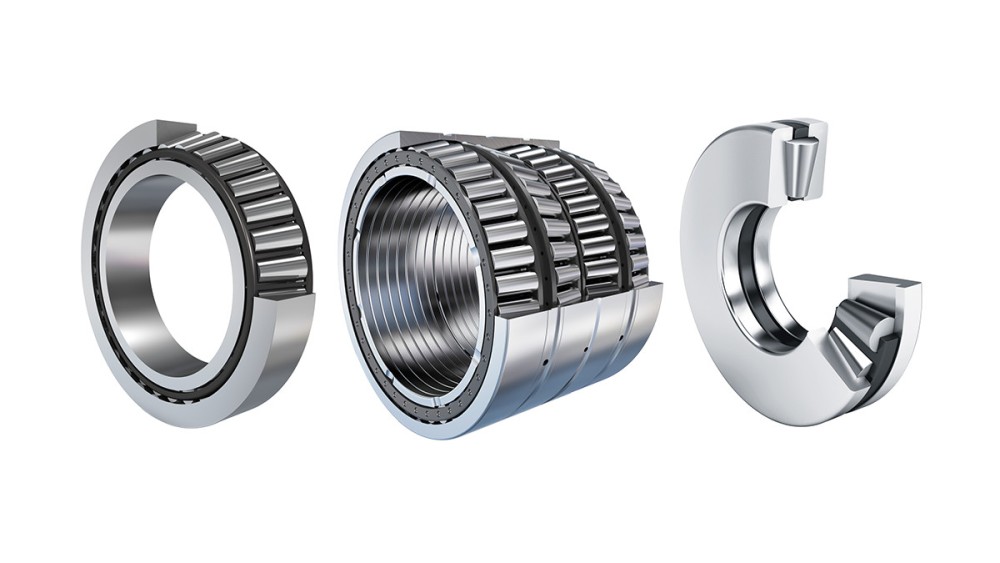

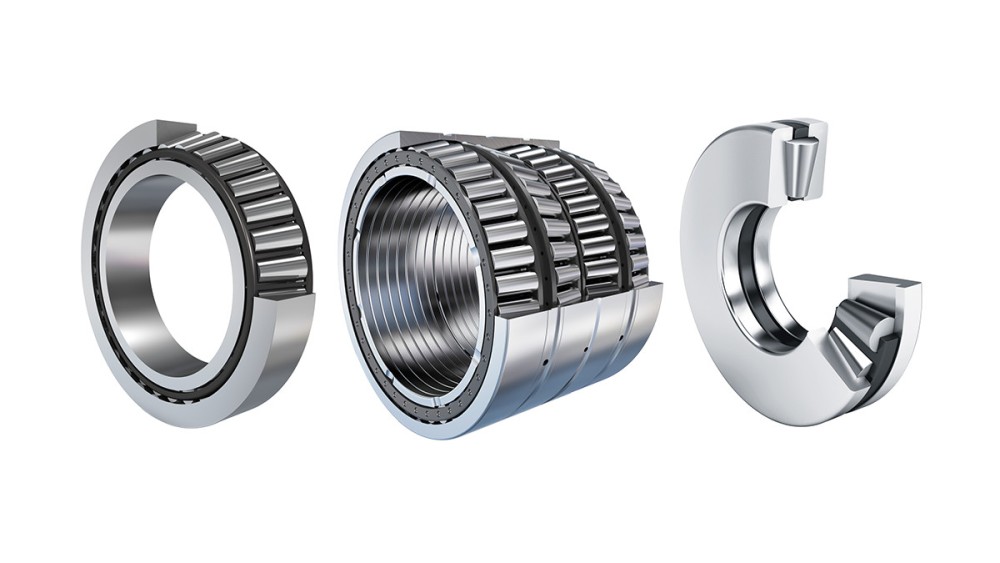

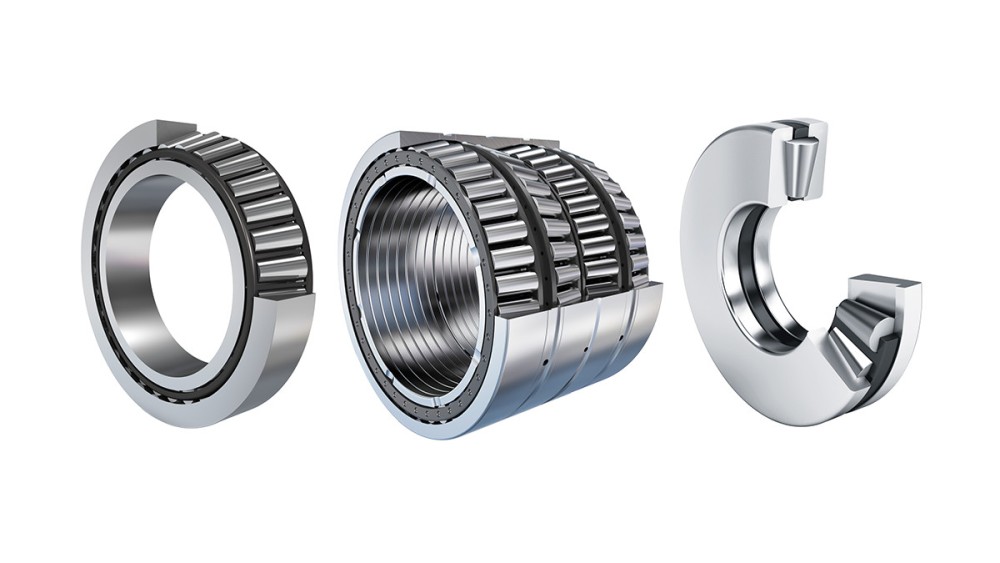

Four-point contact ball slewing turntable bearings

consist of 2 ring seats. Compact structure, light weight, steel ball and arc track contact at 4 points, can bear axial force, radial force and overturning moment at the same time, has strong dynamic load.

Single row cross roller slewing bearing

Composed of 2 or 3 rings. compact structure, light weight, high manufacturing accuracy, small assembly gap and high requirement for installation accuracy. Rollers are 1:1 cross-arranged.

Can be bear axial force, overturning moment and large radial force at the same time,and widely used in lifting transportation, construction machinery and precesion products.

Double row ball slewing bearings

This kind of bearings can support high static loads with simple structures. They are mainly used in situations with variation load position and direction and continuously rotating. Main applications of this kind of bearings are deck hoisting, mining and material handling etc.

Three row roller slewing bearing

Three row roller bearing CZPT to bear all kinds of loads at the same time, it is the largest 1 of the 4 structural products with large axle and radial dimensions and firm structure. Especially suitable for heavy machinery requiring larger diameter, such as bucket wheel stacker and reclaimer, wheel crane, marine crane, port crane, ladle turret,large tonnage truck crane,heavy machinery and so on.

| Type | • Single row 4 point contact ball slewing bearing • Single row crossed cylindrical roller slewing bearings • Double row ball slewing bearings •Double row Roller/ball combination slewing bearing •Three-Row Roller Slew Ring Bearing |

| Rolling elements | Steel ball / Cylinder Roller |

| Rolling elements Material | GCr5/GCr15SiMn/Customized |

| Bearing Material | 50Mn/42CrMo/42CrMo4V /Customized |

| Cage Material | Nylon/ steel /copper |

| Structure | taper pin , Mounting holes,Inner ring ,grease fitting,load plug, seals , roller ,spacer balls or separators |

| Outer diameter | 50-10000mm |

| Bore size | 50-10000mm |

| Mounting hole | Through hole/Tapped hole |

| Raceway hardness | 55-62HRC |

| Inner and outer ring modulation hardness |

229-269HB/Customized |

| Gear type | No gear ,Internal gear , External gear. |

| Embellish grease | EP2 lithium lubricating grease |

| Certificate | ABS.BV,DNV,ISO9001,GL,3.1,3.2 |

| Application area | Ladle turret,Stacker crane,Bucket wheel machine,Solar heliostat Tracking System,port crane, Cabling machine,tower crane , offshore platform,ferris wheel, Palletizing robot,Rotary metallurgical furnace,can packing machine,Wind blade transporter,shield tunneling machine,tube push bench,excavator |

| Brand Name | LYMC |

| Place of Origin | HangZhou ZheJiang |

| Warranty | 12 months |

| Payment term | T/T is our first choice |

|

Packing details |

1,Filling with anti-rust oil 2.Corved with Plastic paper 3.Corved with kraft paper 4.Corved with Blue tie 5.Put in wooden box |

Product Process

Application:

– Excavators – Drilling rigs – Mining Equipments – Cranes -Offshore Equipments – Vehicles – Machine Tools – Wind Turbines

About Us:

HangZhou MC Bearing Technology Co.,Ltd (LYMC),who is manufacture located in bearing zone, focus on Slewing bearing, cross roller bearing and pinion,Dia from 50mm-8000mm, Our team with technical and full experience in the bearing industry.

*Professional in researching, developing, producing & marketing high precision bearings for 16 years;

*Many series bearings are on stock; Factory directly provide, most competitive price;

*Advanced CNC equipment, guarantee product accuracy & stability;

*One stop purchasing, product include cross roller bearing, rotary table bearing, robotic bearing, slewing bearing, angular contact ball bearing, large and extra large custom made bearing, diameter from 50~9000mm;

*Excellent pre-sale & after sale service. We can go to customers’ project site if needed.

*Professional technical & exporting team ensure excellent product design, quotation, delivering, documentation & custom clearance.

Our Service:

FAQ:

1.Q: Are you trading company or manufacturer ?

A: We are professional slewing bearing manufacturer with 20 years’ experience.

2.Q: How long is your delivery time?

A: Generally it is 4-5 days if the goods are in stock. or it is 45 days if the goods are not in

stock, Also it is according to quantity.

3.Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample, it is extra.

4.Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance, balance before shipment.

5.Q: Can you provide special customization according to the working conditions?

A: Sure, we can design and produce the slewing bearings for different working conditions.

6.Q: How about your guarantee?

A: We provide lifelong after-sales technical service.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | High Speed, Cold-Resistant, Corrosion-Resistant, Heat-Resistant |

| Sealing Gland: | Sealed On Both Sides |

| Rolling-Element Number: | Single-Row |

| Roller Type: | Straight Raceway |

| Material: | 50mn/42CrMo |

| Customization: |

Available

| Customized Request |

|---|

Can you explain the installation and alignment considerations for rolling contact bearings?

Proper installation and alignment are crucial for the optimal performance and longevity of rolling contact bearings. Incorrect installation or misalignment can lead to premature wear, increased friction, reduced load-carrying capacity, and potential bearing failure. Here’s a detailed explanation of the installation and alignment considerations for rolling contact bearings:

- Clean and Proper Workspace:

Before installing rolling contact bearings, it is essential to ensure a clean and suitable workspace. The work area should be free from dirt, dust, debris, and contaminants that could enter the bearing during installation. Contamination can cause damage to the bearing surfaces and compromise its performance. Additionally, the workspace should have appropriate tools and equipment to facilitate the installation process, including bearing pullers, mounting tools, and measurement instruments.

- Handling and Storage:

Rolling contact bearings should be handled with care to prevent damage to the bearing surfaces. They should be stored in a clean and dry environment, protected from moisture, dust, and extreme temperatures. During handling, it is important to avoid dropping or impacting the bearings, as this can cause surface damage or internal defects. Proper handling and storage practices help maintain the integrity of the bearings and ensure their performance during installation.

- Shaft and Housing Preparation:

Prior to installing the rolling contact bearings, the shaft and housing surfaces must be prepared appropriately. The shaft and housing should be clean, free from burrs, and have the correct dimensions and tolerances specified by the bearing manufacturer. Any roughness or irregularities on the shaft or housing can affect the fit and alignment of the bearing, leading to performance issues. It may be necessary to use appropriate tools, such as emery cloth or a deburring tool, to smooth the surfaces and ensure proper fitment.

- Bearing Mounting:

When mounting rolling contact bearings, it is essential to follow the manufacturer’s recommended procedures and guidelines. This includes using the appropriate mounting tools and techniques to apply the necessary axial or radial force evenly during installation. Overloading or uneven force application can lead to bearing damage or misalignment. Proper mounting techniques may involve using a press, heat, or specialized mounting tools to ensure the bearing is seated securely and accurately on the shaft or in the housing.

- Alignment:

Accurate alignment of rolling contact bearings is critical for their optimal performance. Misalignment can cause increased friction, premature wear, and reduced load-carrying capacity. It is important to align the bearing with respect to the shaft and housing to ensure proper concentricity and parallelism. Alignment methods may include visual alignment, feeler gauges, dial indicators, laser alignment systems, or other precision alignment tools. The specific alignment requirements may vary depending on the bearing type, application, and manufacturer recommendations.

- Lubrication:

Proper lubrication is essential during the installation of rolling contact bearings. The bearing manufacturer’s recommendations should be followed regarding the type, quantity, and method of lubrication. Lubrication helps reduce friction, dissipate heat, and protect against wear and corrosion. It is important to ensure that the bearing is adequately lubricated during installation to facilitate smooth operation and prevent damage.

- Verification and Testing:

After installation, it is recommended to verify the proper fitment, alignment, and operation of the rolling contact bearings. This may involve checking the axial and radial clearances, measuring runout, and performing functional tests to ensure smooth rotation and proper load distribution. Verification and testing help confirm the successful installation and identify any potential issues that may require adjustment or corrective action.

In summary, proper installation and alignment considerations are essential for the optimal performance and longevity of rolling contact bearings. Following recommended procedures, handling the bearings carefully, preparing the shaft and housing surfaces, ensuring accurate alignment, and providing appropriate lubrication contribute to the successful installation and reliable operation of rolling contact bearings in various applications.

Can you provide guidance on the selection and sizing of rolling contact bearings for specific applications?

Yes, I can provide guidance on the selection and sizing of rolling contact bearings for specific applications. Choosing the right rolling contact bearings involves considering various factors such as load requirements, operating conditions, speed, and environmental factors. Here’s a detailed explanation of the steps involved in selecting and sizing rolling contact bearings:

- Identify Application Requirements:

Start by identifying the specific requirements of your application. Consider factors such as the type and magnitude of the loads the bearing will be subjected to, the operating speed, and any special environmental conditions like temperature, moisture, or exposure to corrosive substances. Understanding these requirements is crucial as it forms the basis for selecting the appropriate rolling contact bearing.

- Analyze Load Conditions:

Next, analyze the load conditions acting on the bearing. Determine if the load is radial, axial, or a combination of both. Consider factors such as the magnitude, direction, and frequency of the load. This analysis helps in determining the appropriate bearing type, such as deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings, or tapered roller bearings, that can handle the specific load conditions effectively.

- Calculate Equivalent Load:

Calculate the equivalent load acting on the bearing. In cases where the load acting on the bearing is a combination of radial and axial loads, it is necessary to calculate the equivalent load. The equivalent load accounts for the differing effects of radial and axial loads on the bearing and helps in determining the required bearing size and capacity.

- Consider Speed and Operating Conditions:

Take into account the speed at which the bearing will operate and the specific operating conditions. Higher speeds may require bearings with special design features or materials to handle the increased centrifugal forces and temperature rise. Consider factors such as lubrication requirements, temperature limits, and any special considerations for factors like shock loads, vibrations, or misalignment. These factors influence the selection of appropriate bearing types and configurations.

- Consult Bearing Manufacturer’s Catalogs:

Refer to the catalogs or technical specifications provided by bearing manufacturers. These catalogs contain detailed information about various bearing types, sizes, load ratings, and performance characteristics. Use the information provided to narrow down the options based on your application requirements and load calculations.

- Verify Bearing Life:

Check the calculated bearing life to ensure it meets the required operational lifespan of your application. Bearing manufacturers provide life calculation formulas based on industry standards such as ISO or ABMA. These formulas take into account factors like load, speed, and reliability requirements to estimate the expected bearing life. Verify that the selected bearing will provide the desired operational lifespan under the given operating conditions.

- Consider Mounting and Dismounting:

Lastly, consider the ease of mounting and dismounting the bearing in your specific application. Evaluate factors such as the bearing’s fit tolerance, the required clearance or preload, and any special mounting or dismounting procedures. Ensure that the selected bearing can be easily installed and maintained in your application.

It is important to note that the selection and sizing of rolling contact bearings can be complex, and it is advisable to seek the assistance of bearing manufacturers, engineers, or experts in the field to ensure the optimal selection for your specific application.

What are rolling contact bearings, and how are they utilized in mechanical systems?

Rolling contact bearings are mechanical components used to facilitate smooth and efficient motion between two or more parts in a mechanical system. They utilize rolling elements, such as balls or rollers, to minimize friction and enable relative motion between the rotating or moving parts. Here’s a detailed explanation of rolling contact bearings and their utilization in mechanical systems:

- Definition and Construction:

Rolling contact bearings consist of an inner ring, an outer ring, rolling elements (balls or rollers), and a cage or retainer that holds the rolling elements in position. The inner and outer rings have raceways, which are carefully machined surfaces that guide the rolling elements. The rolling elements roll between the raceways, reducing friction and enabling smooth rotation or linear motion.

- Types of Rolling Contact Bearings:

There are various types of rolling contact bearings, including:

- Ball Bearings: These bearings use spherical balls as rolling elements and are suitable for applications with light to moderate loads and high-speed requirements. Ball bearings are commonly used in motors, fans, household appliances, and automotive applications.

- Roller Bearings: Roller bearings use cylindrical or tapered rollers as rolling elements. They can handle higher loads and provide better shock absorption than ball bearings. Roller bearings are often found in heavy machinery, construction equipment, and industrial applications.

- Needle Bearings: Needle bearings are a type of roller bearing with long, thin rollers. They have a high load capacity and are used in applications where space is limited and high radial load support is required.

- Thrust Bearings: Thrust bearings are designed to support axial loads and allow for rotational or linear motion in the axial direction. They are commonly used in automotive transmissions, machine tools, and thrust applications.

- Tapered Roller Bearings: Tapered roller bearings have conical rollers and are designed to handle both radial and axial loads. They are commonly used in wheel bearings, gearboxes, and heavy-duty applications.

- Utilization in Mechanical Systems:

Rolling contact bearings are utilized in various mechanical systems for several reasons:

- Reduced Friction: By utilizing rolling elements, rolling contact bearings minimize friction compared to sliding contact bearings. This reduces energy losses, heat generation, and wear, resulting in improved efficiency and extended service life of the mechanical system.

- Smooth Motion: Rolling contact bearings enable smooth and controlled motion between components. They allow for low-friction rotation or linear movement, providing precise and reliable operation in a wide range of applications.

- Load Distribution: Rolling contact bearings distribute loads evenly across their contact surfaces, reducing stress concentrations and preventing premature wear or failure. This enables mechanical systems to handle various loads and forces without compromising performance.

- Positional Accuracy: Rolling contact bearings help maintain accurate positioning of components in mechanical systems, ensuring alignment and reducing the risk of misalignment-related issues. This is crucial in precision machinery, robotics, and other applications where positional accuracy is essential.

- Versatility: Rolling contact bearings are available in different sizes, configurations, and materials to suit a wide range of applications. They can accommodate different load capacities, speeds, and environmental conditions, making them adaptable and versatile in various mechanical systems.

In summary, rolling contact bearings are essential components in mechanical systems. They utilize rolling elements to minimize friction, enable smooth motion, distribute loads, and provide positional accuracy. By utilizing rolling contact bearings, mechanical systems can achieve efficient and reliable operation in a wide range of applications, from small appliances to heavy machinery and industrial equipment.

editor by CX 2024-05-08

China wholesaler Slewing Bearing 023.40.1800 022.40.1800 024.40.1800 Double Row Angular Contact Ball Slewing Bearings Slewing Bearing Crane bearing bronze

Product Description

Product Description

The double row ball slewing bearing has 3 seat rings , the steel ball and the spaces can be directly arranged into the upper and lower races. Two rows of steel balls are fitted according to the force born . Open mode fitting is extraordinary convenient .The load angles of both upper and lower race are 90°,which enable to bear large axial force and the tilting moment.

As the axial and radial dimension of the double row ball slewing bearing are rather large , structural is tightening and can support high static loads. They are mainly used in situations with variational load position and direction and continuously rotating . Especially suitable for tower cranes which require working radius over medium range , mobile crane and loading and unloading machinery .

Product Parameters

Different dia product specification

| Model | Boundary dimensions(mm) | Bolt hole diameter(mm) | Structure dimensions(mm) | Gear parameters(mm) | Basic load ratings | Mass | ||||||||||||||||||

| Non-gear | External gear | Internal gear | D | d | H | D1 | D2 | n | <p | D3 (D | d1 (dT) | H1 | h | n3 | φ3 | m | Da Z | da Z | b | X | Coa 104N | kg | ||

| 571-25-500 | 571-25-500 | 571-25-500 | 616 | 384 | 106 | 580 | 420 | 20 | 18 | 523 | 518 | 96 | 26 | 4 | M10x1 | 5 | 645 | 126 | 355 | 72 | 60 | 0.5 | 121 | 100 |

| 571-25-500 | 571-25-500 | 616 | 384 | 106 | 580 | 420 | 20 | 18 | 523 | 518 | 96 | 26 | 4 | M10x1 | 6 | 648 | 105 | 348 | 59 | 60 | 0.5 | 121 | 100 | |

| 571-25-560 | 571-25-560 | 571-25-560 | 676 | 444 | 106 | 640 | 480 | 20 | 18 | 583 | 577 | 96 | 26 | 4 | M10x1 | 5 | 705 | 138 | 415 | 84 | 60 | 0.5 | 134 | 115 |

| 571-25-560 | 571-25-560 | 676 | 444 | 106 | 640 | 480 | 20 | 18 | 583 | 577 | 96 | 26 | 4 | M10x1 | 6 | 708 | 115 | 408 | 69 | 60 | 0.5 | 134 | 115 | |

| 571-25-630 | 571-25-630 | 571-25-630 | 746 | 514 | 106 | 710 | 550 | 24 | 18 | 653 | 647 | 96 | 26 | 4 | M10x1 | 6 | 792 | 129 | 480 | 81 | 60 | 0.5 | 153 | 130 |

| 571-25-630 | 571-25-630 | 746 | 514 | 106 | 710 | 550 | 24 | 18 | 653 | 647 | 96 | 26 | 4 | M10x1 | 8 | 792 | 96 | 472 | 60 | 60 | 0.5 | 153 | 130 | |

| 571-25-710 | 571-25-710 | 571-25-710 | 826 | 594 | 106 | 790 | 630 | 24 | 18 | 733 | 728 | 96 | 26 | 4 | M10x1 | 6 | 864 | 141 | 558 | 94 | 60 | 0.5 | 173 | 140 |

| 571-25-710 | 571-25-710 | 826 | 594 | 106 | 790 | 630 | 24 | 18 | 733 | 728 | 96 | 26 | 4 | M10x1 | 8 | 864 | 105 | 552 | 70 | 60 | 0.5 | 173 | 140 | |

| 571-30-800 | 571-30-800 | 571-30-800 | 942 | 658 | 124 | 898 | 702 | 30 | 22 | 829 | 823 | 114 | 29 | 6 | M10x1 | 8 | 984 | 120 | 616 | 78 | 80 | 0.5 | 230 | 200 |

| 571-30-800 | 571-30-800 | 942 | 658 | 124 | 898 | 702 | 30 | 22 | 829 | 823 | 114 | 29 | 6 | M10x1 | 10 | 990 | 96 | 610 | 62 | 80 | 0.5 | 230 | 200 | |

| 571-30-900 | 571-30-900 | 571-30-900 | 1042 | 758 | 124 | 998 | 802 | 30 | 22 | 929 | 923 | 114 | 29 | 6 | M10x1 | 8 | 1088 | 133 | 712 | 90 | 80 | 0.5 | 258 | 250 |

| 571-30-900 | 571-30-900 | 1042 | 758 | 124 | 998 | 802 | 30 | 22 | 929 | 923 | 114 | 29 | 6 | M10x1 | 10 | 1090 | 106 | 710 | 72 | 80 | 0.5 | 258 | 250 | |

| 571-30-1000 | 571-30-1000 | 571-30-1000 | 1142 | 858 | 124 | 1098 | 902 | 36 | 22 | 1571 | 1571 | 114 | 29 | 6 | M10x1 | 10 | 1200 | 117 | 810 | 82 | 80 | 0.5 | 286 | 300 |

| 571-30-1000 | 571-30-1000 | 1142 | 858 | 124 | 1098 | 902 | 36 | 22 | 1571 | 1571 | 114 | 29 | 6 | M10x1 | 12 | 1200 | 97 | 792 | 67 | 80 | 0.5 | 286 | 300 | |

| 571-30-1120 | 571-30-1120 | 571-30-1120 | 1262 | 978 | 124 | 1218 | 1571 | 36 | 22 | 1148 | 1143 | 114 | 29 | 6 | M10x1 | 10 | 1320 | 129 | 920 | 93 | 80 | 0.5 | 321 | 340 |

| 571-30-1120 | 571-30-1120 | 1262 | 978 | 124 | 1218 | 1571 | 36 | 22 | 1148 | 1143 | 114 | 29 | 6 | M10x1 | 12 | 1320 | 107 | 912 | 77 | 80 | 0.5 | 321 | 340 | |

| 571-40-1250 | 571-40-1250 | 571-40-1250 | 1426 | 1074 | 160 | 1374 | 1126 | 40 | 26 | 1286 | 1282 | 150 | 39 | 6 | M10x1 | 12 | 1500 | 122 | 1008 | 85 | 90 | 0.5 | 482 | 580 |

| 571-40-1250 | 571-40-1250 | 1426 | 1074 | 160 | 1374 | 1126 | 40 | 26 | 1286 | 1282 | 150 | 39 | 6 | M10x1 | 14 | 1498 | 104 | 1008 | 73 | 90 | 0.5 | 482 | 580 | |

| 571-40-1400 | 571-40-1400 | 571-40-1400 | 1576 | 1224 | 160 | 1524 | 1272 | 40 | 26 | 1436 | 1432 | 150 | 39 | 6 | M10x1 | 12 | 1644 | 134 | 1152 | 97 | 90 | 0.5 | 543 | 650 |

| 571-40-1400 | 571-40-1400 | 1576 | 1224 | 160 | 1524 | 1272 | 40 | 26 | 1436 | 1432 | 150 | 39 | 6 | M10x1 | 14 | 1652 | 115 | 1148 | 83 | 90 | 0.5 | 543 | 650 | |

| 571-40-1600 | 571-40-1600 | 571-40-1600 | 1776 | 1424 | 160 | 1724 | 1476 | 45 | 26 | 1636 | 1632 | 150 | 39 | 8 | M10x1 | 14 | 1848 | 129 | 1344 | 97 | 90 | 0.5 | 620 | 750 |

| 571-40-1600 | 571-40-1600 | 1776 | 1424 | 160 | 1724 | 1476 | 45 | 26 | 1636 | 1632 | 150 | 39 | 8 | M10x1 | 16 | 1856 | 113 | 1344 | 85 | 90 | 0.5 | 620 | 750 | |

| 571-40-1800 | 571-40-1800 | 571-40-1800 | 1976 | 1624 | 160 | 1924 | 1676 | 45 | 26 | 1836 | 1832 | 150 | 39 | 8 | M10x1 | 14 | 2058 | 144 | 1540 | 111 | 90 | 0.5 | 692 | 820 |

| 571-40-1800 | 571-40-1800 | 1976 | 1624 | 160 | 1924 | 1676 | 45 | 26 | 1836 | 1832 | 150 | 39 | 8 | M10x1 | 16 | 2064 | 126 | 1536 | 97 | 90 | 0.5 | 692 | 820 | |

| 571-50-2000 | 571-50-2000 | 571-50-2000 | 2215 | 1785 | 190 | 2149 | 1851 | 48 | 33 | 2038 | 2032 | 178 | 47 | 8 | M10x1 | 16 | 2304 | 141 | 1696 | 107 | 120 | 0.5 | 987 | 1150 |

| 571-50-2000 | 571-50-2000 | 2215 | 1785 | 190 | 2149 | 1851 | 48 | 33 | 2038 | 2032 | 178 | 47 | 8 | M10x1 | 18 | 2304 | 125 | 1692 | 95 | 120 | 0.5 | 987 | 1150 | |

| 571-50-2240 | 571-50-2240 | 571-50-2240 | 2455 | 2571 | 190 | 2389 | 2091 | 48 | 33 | 2278 | 2272 | 178 | 47 | 8 | M10x1 | 16 | 2544 | 156 | 1936 | 122 | 120 | 0.5 | 1110 | 1500 |

| 571-50-2240 | 571-50-2240 | 2455 | 2571 | 190 | 2389 | 2091 | 48 | 33 | 2278 | 2272 | 178 | 47 | 8 | M10x1 | 18 | 2556 | 139 | 1926 | 108 | 120 | 0.5 | 1110 | 1500 | |

| 571-50-2500 | 571-50-2500 | 571-50-2500 | 2715 | 2285 | 190 | 2649 | 2351 | 56 | 33 | 2538 | 2532 | 178 | 47 | 8 | M10x1 | 18 | 2804 | 153 | 2196 | 123 | 120 | 0.5 | 1110 | 1500 |

| 571-50-2500 | 571-50-2500 | 2715 | 2285 | 190 | 2649 | 2351 | 56 | 33 | 2538 | 2532 | 178 | 47 | 8 | M10x1 | 20 | 2820 | 138 | 2180 | 110 | 120 | 0.5 | 1110 | 1500 | |

| 571-50-2800 | 571-50-2800 | 571-50-2800 | 3015 | 2585 | 190 | 2949 | 2651 | 56 | 33 | 2838 | 2832 | 178 | 47 | 8 | M10x1 | 18 | 3114 | 170 | 2484 | 139 | 120 | 0.5 | 1390 | 1900 |

| 571-50-2800 | 571-50-2800 | 3015 | 2585 | 190 | 2949 | 2651 | 56 | 33 | 2838 | 2832 | 178 | 47 | 8 | M10x1 | 20 | 3120 | 153 | 2480 | 125 | 120 | 0.5 | 1390 | 1900 | |

| 571-60-3150 | 571-60-3150 | 571-60-3150 | 3428 | 2872 | 226 | 3338 | 2962 | 56 | 45 | 3198 | 3192 | 214 | 56 | 8 | M10x1 | 20 | 3540 | 174 | 2760 | 139 | 150 | 0.5 | 1870 | 3300 |

| 571-60-3150 | 571-60-3150 | 3428 | 2872 | 226 | 3338 | 2962 | 56 | 45 | 3198 | 3192 | 214 | 56 | 8 | M10x1 | 22 | 3542 | 158 | 2750 | 126 | 150 | 0.5 | 1870 | 3300 | |

| 571-60-3550 | 571-60-3550 | 571-60-3550 | 3828 | 3272 | 226 | 3738 | 3362 | 56 | 45 | 3598 | 3592 | 214 | 56 | 8 | M10x1 | 20 | 3940 | 194 | 3160 | 159 | 150 | 0.5 | 2110 | 3700 |

| 571-60-3550 | 571-60-3550 | 3828 | 3272 | 226 | 3738 | 3362 | 56 | 45 | 3598 | 3592 | 214 | 56 | 8 | M10x1 | 22 | 3938 | 176 | 3168 | 145 | 150 | 0.5 | 2110 | 3700 | |

| 571-60-4000 | 571-60-4000 | 571-60-4000 | 4278 | 3722 | 226 | 4188 | 3812 | 60 | 45 | 4048 | 4042 | 214 | 56 | 10 | M10x1 | 22 | 4400 | 197 | 3608 | 165 | 150 | 0.5 | 2370 | 4200 |

| 571-60-4000 | 571-60-4000 | 4278 | 3722 | 226 | 4188 | 3812 | 60 | 45 | 4048 | 4042 | 214 | 56 | 10 | M10x1 | 25 | 4400 | 173 | 3600 | 145 | 150 | 0.5 | 2370 | 4200 | |

| 571-60-4500 | 571-60-4500 | 571-60-4500 | 4778 | 4222 | 226 | 4688 | 4312 | 60 | 45 | 4548 | 4542 | 214 | 56 | 10 | M10x1 | 22 | 4884 | 219 | 4114 | 188 | 150 | 0.5 | 2670 | 4700 |

| 571-60-4500 | 571-60-4500 | 4778 | 4222 | 226 | 4688 | 4312 | 60 | 45 | 4548 | 4542 | 214 | 56 | 10 | M10x1 | 25 | 4900 | 193 | 4100 | 165 | 150 | 0.5 | 2670 | 4700 | |

Same dia product specification

Internal and external gera

| Designations | Gear parameters | External gear parameters | Internal gear parameters | Weight (kg) | ||||

| External gear | Internal gear | b | m | da | Z | da | Z | |

| 031.25.560 | 033.25.560 | 60 | 5 | 704 | 138 | 417 | 84 | 156 |

| 032.25.560 | 034.25.560 | 60 | 6 | 706.8 | 115 | 410.4 | 69 | |

| 031.25.630 | 033.25.630 | 60 | 6 | 790.8 | 129 | 482.4 | 81 | 175 |

| 032.25.630 | 034.25.630 | 60 | 8 | 790.4 | 96 | 475.2 | 60 | |

| 031.25.710 | 033.25.710 | 60 | 6 | 862.8 | 141 | 560.4 | 94 | 198 |

| 032.25.710 | 034.25.710 | 60 | 8 | 862.4 | 105 | 555.2 | 70 | |

| 031.30.800 | 033.30.800 | 80 | 8 | 982.4 | 120 | 619.2 | 78 | 324 |

| 032.30.900 | 034.30.900 | 80 | 10 | 1088 | 106 | 714 | 72 | |

| 031.30.1000 | 033.30.1000 | 80 | 10 | 1198 | 117 | 814 | 82 | 405 |

| 032.30.1000 | 034.30.1000 | 80 | 12 | 1197.6 | 97 | 796.8 | 67 | |

| 031.30.1120 | 033.30.1120 | 80 | 10 | 1318 | 129 | 924 | 93 | 455 |

| 032.30.1120 | 034.30.1120 | 80 | 12 | 1317.6 | 107 | 916.8 | 77 | |

| 031.40.1250 | 033.40.1250 | 90 | 12 | 1497.6 | 122 | 1012.8 | 85 | 837 |

| 032.40.1250 | 034.40.1250 | 90 | 14 | 1495.2 | 104 | 1013.6 | 73 | |

| 031.40.1400 | 033.40.1400 | 90 | 12 | 1641.6 | 134 | 1156.8 | 97 | 940 |

| 032.40.1400 | 034.40.1400 | 90 | 14 | 1649.2 | 115 | 1153.6 | 83 | |

| 031.40.1600 | 033.40.1600 | 90 | 14 | 1845.2 | 129 | 1349.6 | 97 | 1075 |

| 032.40.1600 | 034.40.1600 | 90 | 16 | 1852.8 | 113 | 1350.4 | 85 | |

| 031.40.1800 | 033.40.1800 | 90 | 14 | 2055.2 | 144 | 1545.6 | 111 | 1213 |

| 032.40.1800 | 034.40.1800 | 90 | 16 | 2060.8 | 126 | 1542.4 | 97 | |

| 031.50.200 | 033.50.2000 | 120 | 16 | 2300.8 | 141 | 1702.4 | 107 | 1921 |

| 032.50.2000 | 034.50.2000 | 120 | 18 | 2300.4 | 125 | 1699.32 | 95 | |

| 031.50.2240 | 033.50.2240 | 120 | 16 | 2540.8 | 156 | 1942.4 | 122 | 2159 |

| 032.50.2240 | 034.50.2240 | 120 | 18 | 2552.4 | 139 | 1933.2 | 108 | |

| 031.50.2500 | 033.50.2500 | 120 | 18 | 2804.4 | 153 | 2203.2 | 123 | 2406 |

| 032.50.2500 | 034.50.2500 | 120 | 20 | 2816 | 138 | 2188 | 110 | |

| 031.50.2800 | 033.50.2800 | 120 | 18 | 3110.4 | 170 | 2491.2 | 139 | 3221 |

| 032.50.2800 | 034.50.2800 | 120 | 20 | 3116 | 153 | 2488 | 125 | |

| 031.60.3150 | 033.60.3150 | 150 | 20 | 3536 | 174 | 2768 | 139 | 4652 |

| 032.60.3150 | 034.60.3150 | 150 | 22 | 3537.6 | 158 | 2758.8 | 126 | |

| 031.60.3550 | 033.60.3550 | 150 | 20 | 3936 | 194 | 3168 | 159 | 5262 |

| 032.60.3550 | 034.60.3550 | 150 | 22 | 3933.6 | 176 | 3176.8 | 145 | |

| 031.60.4000 | 033.60.4000 | 150 | 22 | 4395.6 | 197 | 3616.8 | 165 | 5938 |

| 032.60.4000 | 034.60.4000 | 150 | 25 | 4395 | 173 | 3610 | 145 | |

No gear

| Designations | Dimension (mm) | |||||||||

| Non-geartype | D | d | T | H | h | D1 | d1 | dn | n | n1 |

| 030.25.560 | 676 | 444 | 110 | 100 | 26 | 640 | 480 | 18 | 20 | 4 |

| 676 | 444 | 110 | 100 | 26 | 640 | 480 | 18 | 20 | 4 | |

| 030.25.630 | 746 | 514 | 110 | 100 | 26 | 710 | 550 | 18 | 24 | 4 |

| 746 | 514 | 110 | 100 | 26 | 710 | 550 | 18 | 24 | 4 | |

| 030.25.710 | 826 | 594 | 110 | 100 | 26 | 790 | 630 | 18 | 24 | 4 |

| 826 | 594 | 110 | 100 | 26 | 790 | 630 | 18 | 24 | 4 | |

| 030.30.800 | 942 | 658 | 130 | 120 | 29 | 898 | 702 | 22 | 30 | 6 |

| 942 | 658 | 130 | 120 | 29 | 898 | 702 | 22 | 30 | 6 | |

| 030.30.900 | 1042 | 758 | 130 | 120 | 29 | 998 | 802 | 22 | 30 | 6 |

| 1042 | 758 | 130 | 120 | 29 | 998 | 802 | 22 | 30 | 6 | |

| 030.30.1000 | 1142 | 858 | 130 | 120 | 29 | 1098 | 902 | 22 | 36 | 6 |

| 1142 | 858 | 130 | 120 | 29 | 1098 | 902 | 22 | 36 | 6 | |

| 030.30.1120 | 1262 | 978 | 130 | 120 | 29 | 1218 | 1571 | 22 | 36 | 6 |

| 1262 | 978 | 130 | 120 | 29 | 1218 | 1571 | 22 | 36 | 6 | |

| 030.40.1250 | 1426 | 1074 | 170 | 160 | 39 | 1374 | 1126 | 26 | 40 | 5 |

| 1426 | 1074 | 170 | 160 | 39 | 1374 | 1126 | 26 | 40 | 5 | |

| 030.40.1400 | 1576 | 1224 | 170 | 160 | 39 | 1524 | 1272 | 26 | 40 | 5 |

| 1576 | 1224 | 170 | 160 | 39 | 1524 | 1272 | 26 | 40 | 5 | |

| 030.40.1600 | 1776 | 1424 | 170 | 160 | 39 | 1724 | 1476 | 26 | 45 | 5 |

| 1776 | 1424 | 170 | 160 | 39 | 1724 | 1476 | 26 | 45 | 5 | |

| 030.40.1800 | 1976 | 1624 | 170 | 160 | 39 | 1924 | 1676 | 26 | 45 | 5 |

| 1976 | 1624 | 170 | 160 | 39 | 1924 | 1676 | 26 | 45 | 5 | |

| 030.50.2000 | 2215 | 1785 | 200 | 188 | 47 | 2149 | 1851 | 33 | 48 | 8 |

| 2215 | 1785 | 200 | 188 | 47 | 2149 | 1851 | 33 | 48 | 8 | |

| 030.50.2240 | 2455 | 2571 | 200 | 188 | 47 | 2389 | 2091 | 33 | 48 | 8 |

| 2455 | 2571 | 200 | 188 | 47 | 2389 | 2091 | 33 | 48 | 8 | |

| 030.50.2500 | 2715 | 2285 | 200 | 188 | 47 | 2649 | 2351 | 33 | 56 | 8 |

| 2715 | 2285 | 200 | 188 | 47 | 2649 | 2351 | 33 | 56 | 8 | |

| 030.50.2800 | 3015 | 2585 | 200 | 224 | 47 | 2949 | 2651 | 33 | 56 | 8 |

| 3015 | 2585 | 200 | 224 | 47 | 2949 | 2651 | 33 | 56 | 8 | |

| 030.60.3150 | 3428 | 2872 | 240 | 224 | 56 | 3338 | 2962 | 45 | 56 | 8 |

| 3428 | 2872 | 240 | 224 | 56 | 3338 | 2962 | 45 | 56 | 8 | |

| 030.60.3550 | 3828 | 3272 | 240 | 224 | 56 | 3738 | 3362 | 45 | 56 | 8 |

| 3828 | 3272 | 240 | 224 | 56 | 3738 | 3362 | 45 | 56 | 8 | |

| 030.60.4000 | 4278 | 3722 | 240 | 224 | 56 | 4188 | 3812 | 45 | 60 | 8 |

| 4278 | 3722 | 240 | 224 | 56 | 4188 | 3812 | 45 | 60 | 8 | |

Company Profile

HangZhou solarich machinery Co., Ltd. is a professional manufacturer of bearings, We can design and manufacture single-row ball slewing bearings, double-row ball slewing bearings, three-row roller slewing bearings, ball combination slewing bearings, crossed roller bearings, crossed tapered roller bearings Bearings, slewing drives and custom bearings.

Subordinate factories use high-quality chrome steel and stainless steel as raw materials, specializing in the design, development and manufacture of deep groove ball bearings, stainless steel bearings, stainless steel outer ball bearings , tapered bearings , cylindrical bearings, needle bearing , thrust bearing , bearing housing and non-standard bearings.

Adhering to the business philosophy of “Quality and Integrity”, we will continue to provide excellent bearings and high-quality services to serve global customers

Solutions

Playground Equipment

Slewing bearing can provide excellent performance experience and safety guarantee for amusement equipment, and the durability of slewing bearing is also the main concern of technical engineers. For more than 20 years, slewing bearing solutions have been used in many key applications of large amusement equipment. reflect.

We designed the cross-sectional area to remain the same as the raceway center distance increased, and the slewing ring achieves better dynamic capabilities with less mass.

Key advantages include:

* Lighter weight

* Save spaighter weightce

* Long life and lower maintenance costs

* Better stiffness

* Better lubrication in extreme conditions

Medical Device

With the comprehensive development of scientific and technological strength, the social economyu has been improved faster, and the medical equipment has also been comprehensively improved.

Mining & construction machinery

Mining machinery and heavy construction machinery industry uses a range of different types of highly specialized mobile machinery. . The places where mining machinery and construction machinery are active are mostly mining sites such as mountains and deserts that are far away from ordinary human life. These heavy machinery work in the harshest environments and require continuous low-friction work without reducing load capacity and minimum. assembly and adjustment time. Solving the bearing heating problem caused by the large exciting force, high vibration frequency and continuous operation of vibratory rollers for users has become the focus of the work. Mineral crushing machinery, cutting machinery, screening machinery, loading machinery, conveying machinery and other equipment in the use environment of bearings, users desire products with robustness, durability and high reliability to resist these harsh working conditions.

Transportation vehicle

Metric and inch needle roller bearings have various structural types, mainly including open drawn cup needle roller bearings, closed drawn cup needle roller bearings, needle roller bearings with inner ring and needle roller bearings without inner ring/without inner ring Cage needle roller bearings, caged and cageless needle roller bearings. Widely used in automobiles, motorcycles, mopeds, power tools, textiles, agricultural machinery, printing machinery, construction machinery, automatic instruments and other fields.

Automatic machinery

Industrial robot bearings mainly include 2 categories: 1 is thin-walled bearings, and the other is crossed cylindrical roller bearings. In addition, there are harmonic reducer bearings, linear roller bearings, spherical plain bearings, etc. Bearings with good performance have large bearing capacity, good rigidity, high rotation precision and easy installation.

Packaging & Shipping

FAQ

Q: Are you trading company or manufacturer?

A: We are bearing manufacturer.

Q: How do you control quality of bearing?

A: All products and services passed ISO9001-2008 Quality Certificate.

Q: What is the MOQ?

A: It depends on the bearing type. You can send inquiry or send e-mail for more information.

Q: How about the package?

A: Industrial packing in general condition (Plastic tube+ carton+ pallet). Accept design package when OEM.

Q: How long is the delivery time?

A: It will take about 10 to 40 days, depends on the model and quantity.

Q: How about the shipping?

A: We can arrange the shipment or you may have the forwarder.

Q: Is sample avaiable?

A: Yes, sample order is acceptable.

Q: Can we use our own LOGO or design on bearings?

A: Yes. OEM is acceptable. We can design the bearing with your requirements and use your own LOGO and package design.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Nonstandard |

|---|---|

| Sealing Gland: | Non-Seal |

| Rolling-Element Number: | Double-Row |

| Samples: |

US$ 20/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What are the Common Signs of Wear or Damage in Tapered Roller Bearings?

Identifying signs of wear or damage in tapered roller bearings is crucial for maintaining optimal performance and preventing costly failures. Here are the common signs to look for:

- Abnormal Noise:

Unusual noises, such as grinding, clicking, or rumbling sounds, may indicate damage within the bearing. These noises could result from worn rollers, raceways, or insufficient lubrication.

- Vibration:

Excessive vibration or unusual vibrations not typically present during operation may indicate an issue with the bearing. Vibration can result from misalignment, worn components, or uneven loading.

- Increased Operating Temperature:

If the bearing becomes excessively hot during operation, it could indicate inadequate lubrication, excessive friction, or other issues. Monitoring temperature changes can help identify potential problems.

- Irregular Rotation:

If the bearing experiences irregular rotation, such as sticking or rough movement, it could be due to damaged rollers, misalignment, or improper preload.

- Visible Wear:

Inspect the bearing for visible signs of wear or damage, such as pitting, scoring, discoloration, or deformation of the bearing components.

- Increased Noise or Vibration Under Load:

If the bearing makes more noise or vibrates noticeably when subjected to load, it could indicate that the bearing is unable to handle the applied load properly.

- Uneven Wear:

Uneven wear patterns on the rollers or raceways can suggest misalignment or inadequate lubrication, causing the bearing to experience uneven loading.

- Loss of Performance:

If the bearing’s performance decreases, such as reduced efficiency or increased friction, it may indicate wear, contamination, or other issues affecting the bearing’s operation.

- Looseness or Play:

If there’s excessive play or looseness in the bearing assembly, it could be a sign of worn components or inadequate preload, impacting the bearing’s stability and performance.

- Leaks or Contaminants:

Inspect for leaks of lubricant or the presence of contaminants around the bearing. Leaks can indicate seal damage, and contaminants can accelerate wear.

- Observable Damage to Components:

If any bearing components, such as rollers, cages, or raceways, appear visibly damaged or deformed, immediate attention is necessary to prevent further issues.

Regular inspection and maintenance are essential to catch these signs early and prevent further damage. Addressing wear or damage promptly can extend the bearing’s lifespan and avoid costly downtime.

What Factors should be Considered when Selecting a Tapered Roller Bearing for a Specific Application?

Choosing the right tapered roller bearing for a specific application involves considering various factors to ensure optimal performance and reliability. Here are the key factors to consider:

- Load Requirements:

Assess the types and magnitudes of both radial and axial loads the bearing will experience. Choose a tapered roller bearing with a load capacity that comfortably exceeds the expected loads to prevent premature wear or failure.

- Speed:

Determine the required rotational speed of the bearing. High-speed applications may require bearings designed for reduced friction and heat generation to maintain efficiency and avoid overheating.

- Precision and Tolerance:

Consider the level of precision required for the application. Tapered roller bearings are available in different precision classes, such as ABEC (Annular Bearing Engineering Committee) grades, which impact factors like smoothness and accuracy of rotation.

- Mounting and Installation:

Assess the available space for mounting the bearing and consider the ease of installation. Bearings with adjustable clearance or preload might be advantageous for fine-tuning the bearing’s internal play.

- Temperature and Environment:

Take into account the operating temperature range and environmental conditions of the application. Extreme temperatures or corrosive environments may require specific bearing materials or coatings.

- Lubrication:

Choose an appropriate lubricant based on the application’s speed, temperature, and load conditions. Proper lubrication ensures smooth operation, reduces friction, and prolongs the bearing’s lifespan.

- Cost and Budget:

Consider the budget allocated for bearings. High-precision or specialized bearings may come at a higher cost, but their performance benefits can outweigh the initial investment over the bearing’s service life.

- Application Type:

Identify the specific industry and application in which the bearing will be used. Tapered roller bearings are employed in various sectors, including automotive, heavy machinery, aerospace, and more.

- Expected Lifespan:

Estimate the required bearing lifespan for the application. Factors such as load, speed, and maintenance practices can impact the bearing’s longevity.

- Bearing Size and Design:

Choose a bearing size that fits within the application’s space constraints while providing the necessary load capacity. The design, including the number and arrangement of rollers, can influence load distribution and performance.

- Maintenance Requirements:

Consider the maintenance schedule and accessibility for bearing inspection and replacement. Bearings in applications with limited maintenance intervals may require enhanced durability.

In conclusion, selecting a tapered roller bearing for a specific application involves assessing load requirements, speed, precision, mounting, temperature, lubrication, cost, application type, expected lifespan, bearing size, and maintenance considerations. Careful evaluation of these factors ensures that the chosen bearing meets the demands of the application while providing reliable performance and longevity.

How does Proper Lubrication Impact the Performance and Longevity of Tapered Roller Bearings?

Proper lubrication is essential for ensuring optimal performance and longevity of tapered roller bearings. Lubrication plays a critical role in reducing friction, preventing wear, and managing heat generated during operation. Here’s how proper lubrication impacts tapered roller bearings:

- Reduced Friction:

Lubrication forms a thin film between the rolling elements and raceways, reducing direct metal-to-metal contact. This minimizes friction and the associated heat generation, allowing the bearing to operate smoothly and efficiently.

- Wear Prevention:

Lubrication forms a protective barrier that prevents wear and surface damage. Without proper lubrication, friction can lead to accelerated wear, pitting, and even surface scoring, shortening the bearing’s lifespan.

- Heat Dissipation:

Effective lubrication helps dissipate heat generated during operation. This is especially crucial in high-speed applications where excessive heat can lead to premature bearing failure or degradation of lubricant properties.

- Corrosion Protection:

Lubrication helps create a barrier that protects bearing surfaces from environmental factors that could lead to corrosion. This is particularly important in applications exposed to moisture, chemicals, or other corrosive agents.

- Noise and Vibration Reduction:

Proper lubrication can dampen vibrations and reduce noise by providing a cushioning effect between the rolling elements and raceways. This contributes to smoother and quieter operation.

- Longevity:

Well-lubricated bearings experience less wear and stress, leading to extended service life. Bearings that are inadequately lubricated or run dry are prone to premature failure due to excessive wear, heat buildup, and damage to bearing surfaces.

- Efficiency:

Adequate lubrication maintains the bearing’s efficiency by minimizing energy losses due to friction. Bearings that lack proper lubrication require more energy to overcome higher friction levels, resulting in reduced efficiency.

- Lubrication Methods:

Various lubrication methods are available, including grease lubrication and oil lubrication. The choice depends on factors such as speed, load, temperature, and application requirements.

To ensure proper lubrication:

- Follow Manufacturer Recommendations:

Consult the bearing manufacturer’s recommendations for lubricant type, viscosity, and replenishment intervals.

- Monitor and Maintain:

Regularly monitor the condition of the lubricant and the bearing’s performance. Implement a maintenance schedule for lubricant replacement or replenishment.

- Environmental Considerations:

Consider the operating environment’s temperature, contamination levels, and exposure to external elements. Some applications may require special lubricants for extreme conditions.

In summary, proper lubrication is crucial for maintaining tapered roller bearings’ performance, preventing wear, reducing friction and heat, and extending their lifespan. A well-lubricated bearing contributes to smoother operation, lower maintenance costs, and improved efficiency.

editor by CX 2024-05-06

China Standard Four Point Contact Ball Bearing 90-20 0641/0-07032 Slew Gear Bearing for Tower Crane connecting rod bearing

Product Description

Four Point Contact Ball Bearing 90-20 0641/0-571 Slew Gear Bearing For Tower Crane

Four-point contact ball slewing turntable bearings

consist of 2 ring seats. Compact structure, light weight, steel ball and arc track contact at 4 points, can bear axial force, radial force and overturning moment at the same time, has strong dynamic load.

Single row cross roller slewing bearing

Composed of 2 or 3 rings. compact structure, light weight, high manufacturing accuracy, small assembly gap and high requirement for installation accuracy. Rollers are 1:1 cross-arranged.

Can be bear axial force, overturning moment and large radial force at the same time,and widely used in lifting transportation, construction machinery and precesion products.

Double row ball slewing bearings

This kind of bearings can support high static loads with simple structures. They are mainly used in situations with variation load position and direction and continuously rotating. Main applications of this kind of bearings are deck hoisting, mining and material handling etc.

Three row roller slewing bearing

Three row roller bearing CZPT to bear all kinds of loads at the same time, it is the largest 1 of the 4 structural products with large axle and radial dimensions and firm structure. Especially suitable for heavy machinery requiring larger diameter, such as bucket wheel stacker and reclaimer, wheel crane, marine crane, port crane, ladle turret,large tonnage truck crane,heavy machinery and so on.

| Type | • Single row 4 point contact ball slewing bearing • Single row crossed cylindrical roller slewing bearings • Double row ball slewing bearings •Double row Roller/ball combination slewing bearing •Three-Row Roller Slew Ring Bearing |

| Rolling elements | Steel ball / Cylinder Roller |

| Rolling elements Material | GCr5/GCr15SiMn/Customized |

| Bearing Material | 50Mn/42CrMo/42CrMo4V /Customized |

| Cage Material | Nylon/ steel /copper |

| Structure | taper pin , Mounting holes,Inner ring ,grease fitting,load plug, seals , roller ,spacer balls or separators |

| Outer diameter | 50-10000mm |

| Bore size | 50-10000mm |

| Mounting hole | Through hole/Tapped hole |

| Raceway hardness | 55-62HRC |

| Inner and outer ring modulation hardness |

229-269HB/Customized |

| Gear type | No gear ,Internal gear , External gear. |

| Embellish grease | EP2 lithium lubricating grease |

| Certificate | ABS.BV,DNV,ISO9001,GL,3.1,3.2 |

| Application area | Ladle turret,Stacker crane,Bucket wheel machine,Solar heliostat Tracking System,port crane, Cabling machine,tower crane , offshore platform,ferris wheel, Palletizing robot,Rotary metallurgical furnace,can packing machine,Wind blade transporter,shield tunneling machine,tube push bench,excavator |

| Brand Name | LYMC |

| Place of Origin | HangZhou ZheJiang |

| Warranty | 12 months |

| Payment term | T/T is our first choice |

|

Packing details |

1,Filling with anti-rust oil 2.Corved with Plastic paper 3.Corved with kraft paper 4.Corved with Blue tie 5.Put in wooden box |

Product Process

Application:

– Excavators – Drilling rigs – Mining Equipments – Cranes -Offshore Equipments – Vehicles – Machine Tools – Wind Turbines

About Us:

HangZhou MC Bearing Technology Co.,Ltd (LYMC),who is manufacture located in bearing zone, focus on Slewing bearing, cross roller bearing and pinion,Dia from 50mm-8000mm, Our team with technical and full experience in the bearing industry.

*Professional in researching, developing, producing & marketing high precision bearings for 16 years;

*Many series bearings are on stock; Factory directly provide, most competitive price;

*Advanced CNC equipment, guarantee product accuracy & stability;

*One stop purchasing, product include cross roller bearing, rotary table bearing, robotic bearing, slewing bearing, angular contact ball bearing, large and extra large custom made bearing, diameter from 50~9000mm;

*Excellent pre-sale & after sale service. We can go to customers’ project site if needed.

*Professional technical & exporting team ensure excellent product design, quotation, delivering, documentation & custom clearance.

Our Service:

FAQ:

1.Q: Are you trading company or manufacturer ?

A: We are professional slewing bearing manufacturer with 20 years’ experience.

2.Q: How long is your delivery time?

A: Generally it is 4-5 days if the goods are in stock. or it is 45 days if the goods are not in

stock, Also it is according to quantity.

3.Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample, it is extra.

4.Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance, balance before shipment.

5.Q: Can you provide special customization according to the working conditions?

A: Sure, we can design and produce the slewing bearings for different working conditions.

6.Q: How about your guarantee?

A: We provide lifelong after-sales technical service.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | High Speed, Cold-Resistant, Corrosion-Resistant, Heat-Resistant |

| Sealing Gland: | Sealed On Both Sides |

| Rolling-Element Number: | Single-Row |

| Material: | 50mn/42CrMo |

| Type: | No Gear |

| Samples: |

US$ 240/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do innovations and advancements in rolling contact bearing technology impact their use?

Innovations and advancements in rolling contact bearing technology have a significant impact on their use in various industries. These advancements drive improvements in performance, reliability, efficiency, and versatility of rolling contact bearings. Here’s a detailed explanation of how innovations and advancements in rolling contact bearing technology impact their use:

- Enhanced Performance:

Innovations in rolling contact bearing technology lead to enhanced performance characteristics. Advancements in bearing design, materials, and manufacturing processes result in bearings with improved load-carrying capacity, higher speed capabilities, and increased resistance to wear and fatigue. These enhancements enable rolling contact bearings to withstand higher loads, operate at higher speeds, and provide superior performance in demanding applications. For industries that rely on bearings to support heavy loads or operate in challenging conditions, these advancements translate into improved equipment performance and reliability.

- Extended Service Life:

Advancements in rolling contact bearing technology contribute to extended service life. Innovations in bearing materials, surface treatments, and lubrication techniques help reduce friction, wear, and the risk of premature failure. Newer bearing designs and manufacturing processes ensure better distribution of loads and improved stress distribution, resulting in longer bearing life. The ability of rolling contact bearings to operate reliably for extended periods reduces maintenance requirements, downtime, and overall operating costs for industries that heavily rely on bearings.

- Increased Efficiency:

Advancements in rolling contact bearing technology lead to increased efficiency in various applications. Reduced frictional losses, improved sealing arrangements, and optimized lubrication systems contribute to lower energy consumption and higher overall system efficiency. Bearings with lower friction characteristics result in less power loss, allowing equipment to operate with higher energy efficiency. This is particularly important in industries where energy efficiency is a key consideration, such as automotive, aerospace, and wind energy.

- Expanded Application Range:

Innovations in rolling contact bearing technology enable their use in a broader range of applications. Advancements in bearing materials, coatings, and sealing arrangements enhance their resistance to extreme temperatures, corrosive environments, or other challenging operating conditions. This expands the application possibilities for rolling contact bearings in industries such as oil and gas, mining, chemical processing, and food and beverage. Additionally, advancements in bearing design allow for more compact and lightweight solutions, opening up opportunities for their use in space-constrained applications.

- Integration with Digital Technologies:

The integration of rolling contact bearings with digital technologies is another significant impact of advancements in bearing technology. Sensors and monitoring systems can be incorporated into bearings to collect real-time data on operating conditions, such as temperature, vibration, and load. This data can be used for predictive maintenance, condition monitoring, and optimizing equipment performance. The integration of bearings with digital technologies enables industries to implement proactive maintenance strategies, reduce unplanned downtime, and improve overall equipment reliability.

Overall, innovations and advancements in rolling contact bearing technology have a profound impact on their use in various industries. These advancements result in enhanced performance, extended service life, increased efficiency, expanded application range, and integration with digital technologies. As a result, industries can benefit from improved equipment reliability, reduced maintenance costs, increased productivity, and optimized operational performance.

Are there specific considerations for choosing rolling contact bearings in applications with extreme operating conditions or high precision requirements?

When selecting rolling contact bearings for applications with extreme operating conditions or high precision requirements, there are specific considerations to take into account. Here’s a detailed explanation of these considerations:

- Operating Conditions:

In applications with extreme operating conditions, such as high temperatures, high speeds, or corrosive environments, special attention must be given to the bearing’s ability to withstand these conditions. Considerations include:

- Temperature: High-temperature applications require bearings with heat-resistant materials and lubricants designed to withstand elevated temperatures without degradation. Specialized heat treatment processes may be necessary to enhance the bearing’s ability to handle thermal expansion and avoid premature failure.

- Speed: High-speed applications demand bearings that can operate at significantly higher rotational speeds without excessive friction, heat generation, or loss of precision. Factors such as cage design, lubrication, and material selection play a crucial role in achieving reliable performance at high speeds.

- Corrosion and Chemical Resistance: In corrosive environments or applications exposed to chemicals, bearings with corrosion-resistant materials, such as stainless steel or ceramic, and appropriate sealing mechanisms are essential to prevent premature failure due to chemical attack or rust formation.

- Vibration and Shock: Applications subject to high vibration or shock loads require bearings capable of withstanding these dynamic forces. Special designs, such as extra internal clearance or improved cage stability, may be necessary to ensure reliable operation under such conditions.

- Precision Requirements:

In applications with high precision requirements, such as precision instruments, machine tools, or optical equipment, specific considerations are essential to meet the desired level of accuracy and repeatability. Some key factors include:

- Tolerance and Dimensional Stability: Bearings used in high-precision applications must have strict dimensional tolerances and excellent dimensional stability to ensure precise positioning and alignment. This requires careful control during the manufacturing process and the use of high-quality materials.

- Runout and Radial Clearance: Runout, which refers to the deviation from perfect circularity, and radial clearance, which affects the internal play between the rolling elements and the raceways, must be tightly controlled to achieve the desired precision. Bearings with low runout and minimal radial clearance are preferred for high-precision applications.

- Noise and Vibration: High-precision applications often require low noise and vibration levels. Bearings with optimized designs, such as improved cage stability, precision-ground raceways, and high-quality lubrication, help minimize noise and vibrations, ensuring accurate and quiet operation.

- Lubrication: Proper lubrication is crucial for high-precision bearings to reduce friction, minimize wear, and maintain consistent performance. Lubricants with low viscosity, high stability, and excellent temperature characteristics are typically used in precision applications.

Choosing the right rolling contact bearings for applications with extreme operating conditions or high precision requirements requires careful consideration of factors such as temperature, speed, corrosion resistance, dimensional stability, and lubrication. Consulting with bearing manufacturers or experts can provide valuable guidance in selecting the most suitable bearings to meet the specific application’s demands.

Can you describe the load-carrying capacity and load ratings of rolling contact bearings?

Rolling contact bearings are designed to carry various types of loads in mechanical systems. The load-carrying capacity and load ratings of rolling contact bearings play a crucial role in determining their suitability for specific applications. Here’s a detailed explanation of these concepts:

- Load-Carrying Capacity:

The load-carrying capacity of a rolling contact bearing refers to its ability to support and distribute loads without excessive deformation or failure. It is influenced by factors such as the bearing’s design, material properties, and operating conditions. Rolling contact bearings are primarily designed to carry two types of loads:

- Radial Loads: Radial loads act perpendicular to the axis of rotation and are supported by the bearing’s raceways. Radial loads can arise from the weight of the shaft, centrifugal forces, or external forces applied to the bearing. The load-carrying capacity for radial loads is typically specified by the maximum radial load the bearing can withstand without suffering permanent deformation or reduced performance.

- Axial Loads: Axial loads act parallel to the axis of rotation and are supported by the bearing’s configuration, such as the arrangement of the rolling elements or the presence of thrust surfaces. Axial loads can arise from forces that push or pull along the axis of rotation. The load-carrying capacity for axial loads is typically specified by the maximum axial load the bearing can withstand without experiencing excessive wear or reduced performance.

It’s important to note that the load-carrying capacity of a rolling contact bearing is influenced by factors such as rotational speed, lubrication, temperature, and operating conditions. These factors can affect the performance and durability of the bearing under different load conditions.

- Load Ratings:

Load ratings provide standardized values that indicate the maximum permissible loads a rolling contact bearing can carry under specific operating conditions. These ratings help engineers and designers select bearings that can withstand the expected loads in a given application. The two primary load ratings specified for rolling contact bearings are:

- Dynamic Load Rating: The dynamic load rating (C) represents the maximum load that a bearing can carry for a specified number of revolutions or operating hours without developing excessive wear or fatigue. It is based on the bearing’s ability to withstand rolling contact fatigue, which is the most common mode of failure in rolling contact bearings. The dynamic load rating is typically provided by the bearing manufacturer and is expressed in units of force (such as Newtons or pounds-force).

- Static Load Rating: The static load rating (Co) indicates the maximum load that a bearing can withstand without permanent deformation when the bearing is stationary or subjected to very slow rotational speeds. It represents the load capacity of the bearing under static or slowly changing loads. Similar to the dynamic load rating, the static load rating is also provided by the bearing manufacturer and expressed in units of force.

It’s important to consider both the dynamic and static load ratings when selecting a rolling contact bearing for an application. The dynamic load rating is crucial for assessing the bearing’s ability to withstand the varying loads during operation, while the static load rating provides information about the bearing’s resistance to deformation under stationary or slow-speed conditions.

By considering the load-carrying capacity and load ratings of rolling contact bearings, engineers can choose the appropriate bearing type and size to ensure reliable and efficient operation in their specific applications.

editor by CX 2024-04-30

China supplier Four Point Contact Ball Bearing 230.21.0575.013 Marine Crane Rotary Table Bearing deep groove ball bearing

Product Description

Four Point Contact Ball Bearing 230.21.571.013 Marine Crane Rotary Table Bearing

Four-point contact ball slewing turntable bearings

consist of 2 ring seats. Compact structure, light weight, steel ball and arc track contact at 4 points, can bear axial force, radial force and overturning moment at the same time, has strong dynamic load.

Single row cross roller slewing bearing

Composed of 2 or 3 rings. compact structure, light weight, high manufacturing accuracy, small assembly gap and high requirement for installation accuracy. Rollers are 1:1 cross-arranged.

Can be bear axial force, overturning moment and large radial force at the same time,and widely used in lifting transportation, construction machinery and precesion products.

Double row ball slewing bearings

This kind of bearings can support high static loads with simple structures. They are mainly used in situations with variation load position and direction and continuously rotating. Main applications of this kind of bearings are deck hoisting, mining and material handling etc.

Three row roller slewing bearing

Three row roller bearing CZPT to bear all kinds of loads at the same time, it is the largest 1 of the 4 structural products with large axle and radial dimensions and firm structure. Especially suitable for heavy machinery requiring larger diameter, such as bucket wheel stacker and reclaimer, wheel crane, marine crane, port crane, ladle turret,large tonnage truck crane,heavy machinery and so on.

| Type | • Single row 4 point contact ball slewing bearing • Single row crossed cylindrical roller slewing bearings • Double row ball slewing bearings •Double row Roller/ball combination slewing bearing •Three-Row Roller Slew Ring Bearing |

| Rolling elements | Steel ball / Cylinder Roller |

| Rolling elements Material | GCr5/GCr15SiMn/Customized |

| Bearing Material | 50Mn/42CrMo/42CrMo4V /Customized |

| Cage Material | Nylon/ steel /copper |

| Structure | taper pin , Mounting holes,Inner ring ,grease fitting,load plug, seals , roller ,spacer balls or separators |

| Outer diameter | 50-10000mm |

| Bore size | 50-10000mm |

| Mounting hole | Through hole/Tapped hole |

| Raceway hardness | 55-62HRC |

| Inner and outer ring modulation hardness |

229-269HB/Customized |

| Gear type | No gear ,Internal gear , External gear. |

| Embellish grease | EP2 lithium lubricating grease |

| Certificate | ABS.BV,DNV,ISO9001,GL,3.1,3.2 |

| Application area | Ladle turret,Stacker crane,Bucket wheel machine,Solar heliostat Tracking System,port crane, Cabling machine,tower crane , offshore platform,ferris wheel, Palletizing robot,Rotary metallurgical furnace,can packing machine,Wind blade transporter,shield tunneling machine,tube push bench,excavator |

| Brand Name | LYMC |

| Place of Origin | HangZhou ZheJiang |

| Warranty | 12 months |

| Payment term | T/T is our first choice |

|

Packing details |

1,Filling with anti-rust oil 2.Corved with Plastic paper 3.Corved with kraft paper 4.Corved with Blue tie 5.Put in wooden box |

Product Process

Application:

– Excavators – Drilling rigs – Mining Equipments – Cranes -Offshore Equipments – Vehicles – Machine Tools – Wind Turbines

About Us:

HangZhou MC Bearing Technology Co.,Ltd (LYMC),who is manufacture located in bearing zone, focus on Slewing bearing, cross roller bearing and pinion,Dia from 50mm-8000mm, Our team with technical and full experience in the bearing industry.

*Professional in researching, developing, producing & marketing high precision bearings for 16 years;

*Many series bearings are on stock; Factory directly provide, most competitive price;

*Advanced CNC equipment, guarantee product accuracy & stability;

*One stop purchasing, product include cross roller bearing, rotary table bearing, robotic bearing, slewing bearing, angular contact ball bearing, large and extra large custom made bearing, diameter from 50~9000mm;

*Excellent pre-sale & after sale service. We can go to customers’ project site if needed.

*Professional technical & exporting team ensure excellent product design, quotation, delivering, documentation & custom clearance.

Our Service:

FAQ:

1.Q: Are you trading company or manufacturer ?

A: We are professional slewing bearing manufacturer with 20 years’ experience.

2.Q: How long is your delivery time?

A: Generally it is 4-5 days if the goods are in stock. or it is 45 days if the goods are not in

stock, Also it is according to quantity.

3.Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample, it is extra.

4.Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance, balance before shipment.

5.Q: Can you provide special customization according to the working conditions?

A: Sure, we can design and produce the slewing bearings for different working conditions.

6.Q: How about your guarantee?

A: We provide lifelong after-sales technical service.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | High Speed, Cold-Resistant, Corrosion-Resistant, Heat-Resistant |

| Sealing Gland: | Sealed On Both Sides |

| Rolling-Element Number: | Single-Row |

| Roller Type: | Straight Raceway |

| Material: | 50mn/42CrMo |

| Customization: |

Available

| Customized Request |

|---|

What is the impact of proper lubrication and maintenance on the performance and lifespan of rolling contact bearings?

Proper lubrication and maintenance have a significant impact on the performance and lifespan of rolling contact bearings. Adequate lubrication ensures smooth operation, reduces friction, prevents wear, and extends the service life of the bearings. Here’s a detailed explanation of the impact of proper lubrication and maintenance on rolling contact bearings:

- Reduced Friction and Wear:

Proper lubrication forms a thin film of lubricant between the rolling elements and the raceways of the bearing. This lubricating film reduces friction and wear by minimizing direct metal-to-metal contact. It prevents the surfaces from rubbing against each other, reducing frictional forces and minimizing wear on the bearing components. Reduced friction and wear contribute to smoother operation, improved efficiency, and increased bearing lifespan.

- Heat Dissipation:

Lubrication in rolling contact bearings helps dissipate heat generated during operation. The lubricant absorbs and carries away heat from the bearing, preventing excessive temperature rise. Adequate heat dissipation is crucial for maintaining proper operating conditions and preventing thermal damage to the bearing components. Proper lubrication ensures efficient heat transfer, which in turn contributes to the overall performance and durability of the bearing.

- Protection Against Corrosion and Contamination:

Lubrication acts as a protective barrier, preventing corrosion and contamination of rolling contact bearings. The lubricant creates a barrier that shields the bearing surfaces from moisture, dust, dirt, and other contaminants that can lead to corrosion and premature wear. By providing a protective layer, proper lubrication helps maintain the integrity of the bearing components and extends their lifespan.

- Load Distribution:

Proper lubrication ensures effective load distribution within rolling contact bearings. The lubricant helps distribute the applied loads evenly across the rolling elements and the raceways, minimizing stress concentrations and preventing premature fatigue failure. By promoting even load distribution, lubrication enhances the load-carrying capacity and longevity of the bearing.

- Prevention of Excessive Clearance:

Over time, rolling contact bearings may experience wear, which can result in increased clearance between the rolling elements and the raceways. Proper lubrication helps reduce this clearance by filling the gaps and providing a cushioning effect. By minimizing excessive clearance, lubrication maintains the proper functioning and performance of the bearing, preventing issues such as vibration, noise, and reduced load-carrying capacity.

- Maintenance and Inspection:

Regular maintenance and inspection are essential for optimizing the performance and lifespan of rolling contact bearings. Maintenance activities may include lubricant replenishment, cleaning, and periodic replacement of worn-out bearings. Regular inspections allow for the early detection of any signs of damage, excessive wear, or inadequate lubrication. Timely maintenance and inspections help identify and address potential issues before they escalate, ensuring the continued reliability and longevity of the bearings.

In conclusion, proper lubrication and maintenance significantly impact the performance and lifespan of rolling contact bearings. Adequate lubrication reduces friction, prevents wear, dissipates heat, and protects against corrosion and contamination. It promotes even load distribution and helps maintain the proper functioning of the bearing. Regular maintenance and inspections further ensure optimal performance and allow for timely intervention to address any potential issues. By following proper lubrication practices and conducting regular maintenance, the service life of rolling contact bearings can be extended, leading to improved efficiency, reduced downtime, and cost savings in various applications.

Can you describe the various types of seals and shields used with rolling contact bearings for contamination prevention?

Various types of seals and shields are used with rolling contact bearings to prevent contamination and protect the bearing internals. Here’s a detailed description of the commonly used seals and shields:

- Contact Seals:

Contact seals, also known as lip seals or radial seals, are designed to provide a barrier against contaminants while maintaining lubricant retention within the bearing. These seals consist of a flexible lip that makes contact with the inner or outer ring of the bearing. The lip is typically made of synthetic rubber or elastomeric material. Contact seals effectively prevent the entry of solid particles, liquids, and other contaminants into the bearing. They are suitable for applications with moderate operating speeds and rotational requirements where the sealing function takes priority over low friction.

- Non-Contact Seals:

Non-contact seals, also known as labyrinth seals or gap seals, create a labyrinthine path that hinders the entry of contaminants into the bearing. These seals do not make physical contact with the bearing rings, resulting in lower friction and reduced heat generation compared to contact seals. Non-contact seals are typically constructed using metallic or non-metallic components with precise geometries to create a tortuous path for contaminants. They are suitable for high-speed applications and environments where low friction and minimal heat generation are important considerations.

- Shields:

Shields, also referred to as metal shields or non-contact shields, provide a physical barrier between the rolling elements and the external environment. Shields are typically made of metal, such as steel, and are attached to the outer ring of the bearing. They cover a portion of the bearing’s circumference, leaving a small gap for the rolling elements to function. Shields offer effective protection against larger particles and prevent the direct contact of contaminants with the rolling elements. However, they do not provide a complete seal, allowing for limited air circulation and lubricant flow within the bearing.

- Hybrid Seals:

Hybrid seals combine the advantages of contact seals and non-contact seals. These seals use a combination of contacting and non-contacting elements to provide enhanced protection against contamination. Hybrid seals are designed to reduce friction and heat generation while offering improved sealing performance compared to contact seals. They typically incorporate a non-contacting labyrinth or gap seal with additional contact elements, such as lip seals or brush seals, to provide a more effective barrier against contaminants.

- Ingress Protection (IP) Ratings:

In addition to the specific seal and shield types, rolling contact bearings may also be assigned Ingress Protection (IP) ratings. IP ratings indicate the level of protection provided against solid particles, such as dust and dirt, as well as liquids, such as water and oil. The IP rating is typically represented by a two-digit number, where the first digit represents the level of protection against solid particles, and the second digit represents the level of protection against liquids. Higher IP ratings indicate greater protection against contaminants.

The selection of the appropriate seal or shield type depends on various factors, including the application requirements, operating conditions, contamination risks, and desired friction characteristics. Manufacturers typically provide information on the recommended sealing options for their bearing products, considering the specific application needs and environmental conditions.

Can you describe the load-carrying capacity and load ratings of rolling contact bearings?

Rolling contact bearings are designed to carry various types of loads in mechanical systems. The load-carrying capacity and load ratings of rolling contact bearings play a crucial role in determining their suitability for specific applications. Here’s a detailed explanation of these concepts:

- Load-Carrying Capacity: