Product Description

Slew Gear 061.20.571.100.11.1503 Four Point Contact Ball Bearing For JIB Crane

Four-point contact ball slewing turntable bearings

consist of 2 ring seats. Compact structure, light weight, steel ball and arc track contact at 4 points, can bear axial force, radial force and overturning moment at the same time, has strong dynamic load.

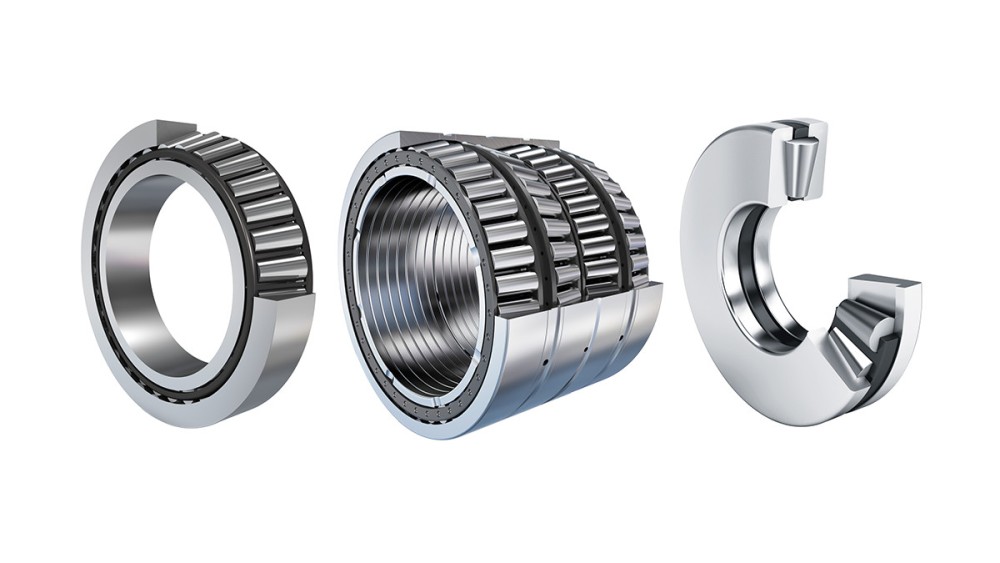

Single row cross roller slewing bearing

Composed of 2 or 3 rings. compact structure, light weight, high manufacturing accuracy, small assembly gap and high requirement for installation accuracy. Rollers are 1:1 cross-arranged.

Can be bear axial force, overturning moment and large radial force at the same time,and widely used in lifting transportation, construction machinery and precesion products.

Double row ball slewing bearings

This kind of bearings can support high static loads with simple structures. They are mainly used in situations with variation load position and direction and continuously rotating. Main applications of this kind of bearings are deck hoisting, mining and material handling etc.

Three row roller slewing bearing

Three row roller bearing CZPT to bear all kinds of loads at the same time, it is the largest 1 of the 4 structural products with large axle and radial dimensions and firm structure. Especially suitable for heavy machinery requiring larger diameter, such as bucket wheel stacker and reclaimer, wheel crane, marine crane, port crane, ladle turret,large tonnage truck crane,heavy machinery and so on.

| Type | • Single row 4 point contact ball slewing bearing • Single row crossed cylindrical roller slewing bearings • Double row ball slewing bearings •Double row Roller/ball combination slewing bearing •Three-Row Roller Slew Ring Bearing |

| Rolling elements | Steel ball / Cylinder Roller |

| Rolling elements Material | GCr5/GCr15SiMn/Customized |

| Bearing Material | 50Mn/42CrMo/42CrMo4V /Customized |

| Cage Material | Nylon/ steel /copper |

| Structure | taper pin , Mounting holes,Inner ring ,grease fitting,load plug, seals , roller ,spacer balls or separators |

| Outer diameter | 50-10000mm |

| Bore size | 50-10000mm |

| Mounting hole | Through hole/Tapped hole |

| Raceway hardness | 55-62HRC |

| Inner and outer ring modulation hardness |

229-269HB/Customized |

| Gear type | No gear ,Internal gear , External gear. |

| Embellish grease | EP2 lithium lubricating grease |

| Certificate | ABS.BV,DNV,ISO9001,GL,3.1,3.2 |

| Application area | Ladle turret,Stacker crane,Bucket wheel machine,Solar heliostat Tracking System,port crane, Cabling machine,tower crane , offshore platform,ferris wheel, Palletizing robot,Rotary metallurgical furnace,can packing machine,Wind blade transporter,shield tunneling machine,tube push bench,excavator |

| Brand Name | LYMC |

| Place of Origin | HangZhou ZheJiang |

| Warranty | 12 months |

| Payment term | T/T is our first choice |

|

Packing details |

1,Filling with anti-rust oil 2.Corved with Plastic paper 3.Corved with kraft paper 4.Corved with Blue tie 5.Put in wooden box |

Product Process

Application:

– Excavators – Drilling rigs – Mining Equipments – Cranes -Offshore Equipments – Vehicles – Machine Tools – Wind Turbines

About Us:

HangZhou MC Bearing Technology Co.,Ltd (LYMC),who is manufacture located in bearing zone, focus on Slewing bearing, cross roller bearing and pinion,Dia from 50mm-8000mm, Our team with technical and full experience in the bearing industry.

*Professional in researching, developing, producing & marketing high precision bearings for 16 years;

*Many series bearings are on stock; Factory directly provide, most competitive price;

*Advanced CNC equipment, guarantee product accuracy & stability;

*One stop purchasing, product include cross roller bearing, rotary table bearing, robotic bearing, slewing bearing, angular contact ball bearing, large and extra large custom made bearing, diameter from 50~9000mm;

*Excellent pre-sale & after sale service. We can go to customers’ project site if needed.

*Professional technical & exporting team ensure excellent product design, quotation, delivering, documentation & custom clearance.

Our Service:

FAQ:

1.Q: Are you trading company or manufacturer ?

A: We are professional slewing bearing manufacturer with 20 years’ experience.

2.Q: How long is your delivery time?

A: Generally it is 4-5 days if the goods are in stock. or it is 45 days if the goods are not in

stock, Also it is according to quantity.

3.Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample, it is extra.

4.Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance, balance before shipment.

5.Q: Can you provide special customization according to the working conditions?

A: Sure, we can design and produce the slewing bearings for different working conditions.

6.Q: How about your guarantee?

A: We provide lifelong after-sales technical service.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Standard or Nonstandard: | Standard |

|---|---|

| Feature: | High Speed, Cold-Resistant, Corrosion-Resistant, Heat-Resistant |

| Sealing Gland: | Sealed On Both Sides |

| Rolling-Element Number: | Single-Row |

| Roller Type: | Straight Raceway |

| Material: | 50mn/42CrMo |

| Customization: |

Available

| Customized Request |

|---|

Can you explain the installation and alignment considerations for rolling contact bearings?

Proper installation and alignment are crucial for the optimal performance and longevity of rolling contact bearings. Incorrect installation or misalignment can lead to premature wear, increased friction, reduced load-carrying capacity, and potential bearing failure. Here’s a detailed explanation of the installation and alignment considerations for rolling contact bearings:

- Clean and Proper Workspace:

Before installing rolling contact bearings, it is essential to ensure a clean and suitable workspace. The work area should be free from dirt, dust, debris, and contaminants that could enter the bearing during installation. Contamination can cause damage to the bearing surfaces and compromise its performance. Additionally, the workspace should have appropriate tools and equipment to facilitate the installation process, including bearing pullers, mounting tools, and measurement instruments.

- Handling and Storage:

Rolling contact bearings should be handled with care to prevent damage to the bearing surfaces. They should be stored in a clean and dry environment, protected from moisture, dust, and extreme temperatures. During handling, it is important to avoid dropping or impacting the bearings, as this can cause surface damage or internal defects. Proper handling and storage practices help maintain the integrity of the bearings and ensure their performance during installation.

- Shaft and Housing Preparation:

Prior to installing the rolling contact bearings, the shaft and housing surfaces must be prepared appropriately. The shaft and housing should be clean, free from burrs, and have the correct dimensions and tolerances specified by the bearing manufacturer. Any roughness or irregularities on the shaft or housing can affect the fit and alignment of the bearing, leading to performance issues. It may be necessary to use appropriate tools, such as emery cloth or a deburring tool, to smooth the surfaces and ensure proper fitment.

- Bearing Mounting:

When mounting rolling contact bearings, it is essential to follow the manufacturer’s recommended procedures and guidelines. This includes using the appropriate mounting tools and techniques to apply the necessary axial or radial force evenly during installation. Overloading or uneven force application can lead to bearing damage or misalignment. Proper mounting techniques may involve using a press, heat, or specialized mounting tools to ensure the bearing is seated securely and accurately on the shaft or in the housing.

- Alignment:

Accurate alignment of rolling contact bearings is critical for their optimal performance. Misalignment can cause increased friction, premature wear, and reduced load-carrying capacity. It is important to align the bearing with respect to the shaft and housing to ensure proper concentricity and parallelism. Alignment methods may include visual alignment, feeler gauges, dial indicators, laser alignment systems, or other precision alignment tools. The specific alignment requirements may vary depending on the bearing type, application, and manufacturer recommendations.

- Lubrication:

Proper lubrication is essential during the installation of rolling contact bearings. The bearing manufacturer’s recommendations should be followed regarding the type, quantity, and method of lubrication. Lubrication helps reduce friction, dissipate heat, and protect against wear and corrosion. It is important to ensure that the bearing is adequately lubricated during installation to facilitate smooth operation and prevent damage.

- Verification and Testing:

After installation, it is recommended to verify the proper fitment, alignment, and operation of the rolling contact bearings. This may involve checking the axial and radial clearances, measuring runout, and performing functional tests to ensure smooth rotation and proper load distribution. Verification and testing help confirm the successful installation and identify any potential issues that may require adjustment or corrective action.

In summary, proper installation and alignment considerations are essential for the optimal performance and longevity of rolling contact bearings. Following recommended procedures, handling the bearings carefully, preparing the shaft and housing surfaces, ensuring accurate alignment, and providing appropriate lubrication contribute to the successful installation and reliable operation of rolling contact bearings in various applications.

Can you provide guidance on the selection and sizing of rolling contact bearings for specific applications?

Yes, I can provide guidance on the selection and sizing of rolling contact bearings for specific applications. Choosing the right rolling contact bearings involves considering various factors such as load requirements, operating conditions, speed, and environmental factors. Here’s a detailed explanation of the steps involved in selecting and sizing rolling contact bearings:

- Identify Application Requirements:

Start by identifying the specific requirements of your application. Consider factors such as the type and magnitude of the loads the bearing will be subjected to, the operating speed, and any special environmental conditions like temperature, moisture, or exposure to corrosive substances. Understanding these requirements is crucial as it forms the basis for selecting the appropriate rolling contact bearing.

- Analyze Load Conditions:

Next, analyze the load conditions acting on the bearing. Determine if the load is radial, axial, or a combination of both. Consider factors such as the magnitude, direction, and frequency of the load. This analysis helps in determining the appropriate bearing type, such as deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings, or tapered roller bearings, that can handle the specific load conditions effectively.

- Calculate Equivalent Load:

Calculate the equivalent load acting on the bearing. In cases where the load acting on the bearing is a combination of radial and axial loads, it is necessary to calculate the equivalent load. The equivalent load accounts for the differing effects of radial and axial loads on the bearing and helps in determining the required bearing size and capacity.

- Consider Speed and Operating Conditions:

Take into account the speed at which the bearing will operate and the specific operating conditions. Higher speeds may require bearings with special design features or materials to handle the increased centrifugal forces and temperature rise. Consider factors such as lubrication requirements, temperature limits, and any special considerations for factors like shock loads, vibrations, or misalignment. These factors influence the selection of appropriate bearing types and configurations.

- Consult Bearing Manufacturer’s Catalogs:

Refer to the catalogs or technical specifications provided by bearing manufacturers. These catalogs contain detailed information about various bearing types, sizes, load ratings, and performance characteristics. Use the information provided to narrow down the options based on your application requirements and load calculations.

- Verify Bearing Life:

Check the calculated bearing life to ensure it meets the required operational lifespan of your application. Bearing manufacturers provide life calculation formulas based on industry standards such as ISO or ABMA. These formulas take into account factors like load, speed, and reliability requirements to estimate the expected bearing life. Verify that the selected bearing will provide the desired operational lifespan under the given operating conditions.

- Consider Mounting and Dismounting:

Lastly, consider the ease of mounting and dismounting the bearing in your specific application. Evaluate factors such as the bearing’s fit tolerance, the required clearance or preload, and any special mounting or dismounting procedures. Ensure that the selected bearing can be easily installed and maintained in your application.

It is important to note that the selection and sizing of rolling contact bearings can be complex, and it is advisable to seek the assistance of bearing manufacturers, engineers, or experts in the field to ensure the optimal selection for your specific application.

What are rolling contact bearings, and how are they utilized in mechanical systems?

Rolling contact bearings are mechanical components used to facilitate smooth and efficient motion between two or more parts in a mechanical system. They utilize rolling elements, such as balls or rollers, to minimize friction and enable relative motion between the rotating or moving parts. Here’s a detailed explanation of rolling contact bearings and their utilization in mechanical systems:

- Definition and Construction:

Rolling contact bearings consist of an inner ring, an outer ring, rolling elements (balls or rollers), and a cage or retainer that holds the rolling elements in position. The inner and outer rings have raceways, which are carefully machined surfaces that guide the rolling elements. The rolling elements roll between the raceways, reducing friction and enabling smooth rotation or linear motion.

- Types of Rolling Contact Bearings:

There are various types of rolling contact bearings, including:

- Ball Bearings: These bearings use spherical balls as rolling elements and are suitable for applications with light to moderate loads and high-speed requirements. Ball bearings are commonly used in motors, fans, household appliances, and automotive applications.

- Roller Bearings: Roller bearings use cylindrical or tapered rollers as rolling elements. They can handle higher loads and provide better shock absorption than ball bearings. Roller bearings are often found in heavy machinery, construction equipment, and industrial applications.

- Needle Bearings: Needle bearings are a type of roller bearing with long, thin rollers. They have a high load capacity and are used in applications where space is limited and high radial load support is required.

- Thrust Bearings: Thrust bearings are designed to support axial loads and allow for rotational or linear motion in the axial direction. They are commonly used in automotive transmissions, machine tools, and thrust applications.

- Tapered Roller Bearings: Tapered roller bearings have conical rollers and are designed to handle both radial and axial loads. They are commonly used in wheel bearings, gearboxes, and heavy-duty applications.

- Utilization in Mechanical Systems:

Rolling contact bearings are utilized in various mechanical systems for several reasons:

- Reduced Friction: By utilizing rolling elements, rolling contact bearings minimize friction compared to sliding contact bearings. This reduces energy losses, heat generation, and wear, resulting in improved efficiency and extended service life of the mechanical system.

- Smooth Motion: Rolling contact bearings enable smooth and controlled motion between components. They allow for low-friction rotation or linear movement, providing precise and reliable operation in a wide range of applications.

- Load Distribution: Rolling contact bearings distribute loads evenly across their contact surfaces, reducing stress concentrations and preventing premature wear or failure. This enables mechanical systems to handle various loads and forces without compromising performance.

- Positional Accuracy: Rolling contact bearings help maintain accurate positioning of components in mechanical systems, ensuring alignment and reducing the risk of misalignment-related issues. This is crucial in precision machinery, robotics, and other applications where positional accuracy is essential.

- Versatility: Rolling contact bearings are available in different sizes, configurations, and materials to suit a wide range of applications. They can accommodate different load capacities, speeds, and environmental conditions, making them adaptable and versatile in various mechanical systems.

In summary, rolling contact bearings are essential components in mechanical systems. They utilize rolling elements to minimize friction, enable smooth motion, distribute loads, and provide positional accuracy. By utilizing rolling contact bearings, mechanical systems can achieve efficient and reliable operation in a wide range of applications, from small appliances to heavy machinery and industrial equipment.

editor by CX 2024-05-08