Product Description

| Bearing model | Bore(mm) | O.D(mm) | Width (mm) | Load Rating(KN) | Maximumspeed(rpm) | Weight (Kg) | ||

| Dynamic | Static | Grease | Oil | |||||

| 5200 | 10 | 30 | 14 | 6.95 | 3.8 | 14000 | 19000 | 0.049 |

| 5201 | 12 | 32 | 15.9 | 9.15 | 5.05 | 13000 | 17000 | 0.057 |

| 5202 | 15 | 35 | 15.9 | 10 | 6.05 | 11000 | 15000 | 0.064 |

| 5203 | 17 | 40 | 17.5 | 13.2 | 8.15 | 10000 | 14000 | 0.091 |

| 5204 | 20 | 47 | 20.6 | 19.7 | 12.6 | 8800 | 12000 | 0.12 |

| 5205 | 25 | 52 | 20.6 | 21.4 | 14.8 | 7700 | 10000 | 0.19 |

| 5206 | 30 | 62 | 23.8 | 29.7 | 21.3 | 6400 | 8600 | 0.29 |

| 5207 | 35 | 72 | 26.7 | 39.2 | 29 | 5500 | 7300 | 0.43 |

| 5208 | 40 | 80 | 30.2 | 44.4 | 33.6 | 5000 | 6700 | 0.57 |

| 5209 | 45 | 85 | 30.2 | 49.9 | 38.4 | 4600 | 6100 | 0.62 |

| 5210 | 50 | 90 | 30.2 | 53.3 | 43 | 4300 | 5600 | 0.67 |

| 5211 | 55 | 100 | 33.3 | 65.9 | 55.2 | 3800 | 5100 | 0.96 |

| 5212 | 60 | 110 | 36.5 | 74.4 | 60.8 | 3500 | 4700 | 1.36 |

| 5213 | 65 | 120 | 38.1 | 86.8 | 75.3 | 3200 | 4300 | 1.66 |

| 5214 | 70 | 125 | 39.7 | 94.5 | 82.6 | 3100 | 4100 | 1.81 |

| 5215 | 75 | 130 | 41.3 | 92.4 | 120 | 2900 | 3900 | 2.1 |

| 5216 | 80 | 140 | 44.4 | 97.5 | 121 | 2700 | 3600 | 2.64 |

FAQ

ZHangZhoug Shengya Bearing Technology Co., Ltd – Product Description

Frequently Asked Questions

- Can the product be customized?

Yes, we offer customization options. - What is the delivery time after confirming an order?

If we have stock, goods can be sent within 1 week after 100% payment. If not, delivery time varies. - Can my logo be printed on the product?

Yes, we can print your logo with your trademark authorization. - What are the payment terms?

Payment terms are ***% deposit and 70% balance before shipment.

Sample Service

- OEM customization available based on samples.

- Sample finishing time: Within 3 days with stock, within 10 days with molds. OEM samples vary.

Payment

Accepted payment methods: T/T, L/C, DP. Please inform us once payment is made for prompt production arrangement.

Shipping

Samples delivered by DHL, ***, UPS, FedEx. Bulk orders shipped by sea.

Package

Regular packaging includes blank carton, polybag, or wooden pallet. Customized packaging available.

Delivery Time

Sample delivery within 3-10 days if in stock. Large quantity orders take approximately 30-50 days for delivery.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 45° |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Double |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

| Samples: |

US$ 8/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

What are the Common Signs of Wear or Damage in Tapered Roller Bearings?

Identifying signs of wear or damage in tapered roller bearings is crucial for maintaining optimal performance and preventing costly failures. Here are the common signs to look for:

- Abnormal Noise:

Unusual noises, such as grinding, clicking, or rumbling sounds, may indicate damage within the bearing. These noises could result from worn rollers, raceways, or insufficient lubrication.

- Vibration:

Excessive vibration or unusual vibrations not typically present during operation may indicate an issue with the bearing. Vibration can result from misalignment, worn components, or uneven loading.

- Increased Operating Temperature:

If the bearing becomes excessively hot during operation, it could indicate inadequate lubrication, excessive friction, or other issues. Monitoring temperature changes can help identify potential problems.

- Irregular Rotation:

If the bearing experiences irregular rotation, such as sticking or rough movement, it could be due to damaged rollers, misalignment, or improper preload.

- Visible Wear:

Inspect the bearing for visible signs of wear or damage, such as pitting, scoring, discoloration, or deformation of the bearing components.

- Increased Noise or Vibration Under Load:

If the bearing makes more noise or vibrates noticeably when subjected to load, it could indicate that the bearing is unable to handle the applied load properly.

- Uneven Wear:

Uneven wear patterns on the rollers or raceways can suggest misalignment or inadequate lubrication, causing the bearing to experience uneven loading.

- Loss of Performance:

If the bearing’s performance decreases, such as reduced efficiency or increased friction, it may indicate wear, contamination, or other issues affecting the bearing’s operation.

- Looseness or Play:

If there’s excessive play or looseness in the bearing assembly, it could be a sign of worn components or inadequate preload, impacting the bearing’s stability and performance.

- Leaks or Contaminants:

Inspect for leaks of lubricant or the presence of contaminants around the bearing. Leaks can indicate seal damage, and contaminants can accelerate wear.

- Observable Damage to Components:

If any bearing components, such as rollers, cages, or raceways, appear visibly damaged or deformed, immediate attention is necessary to prevent further issues.

Regular inspection and maintenance are essential to catch these signs early and prevent further damage. Addressing wear or damage promptly can extend the bearing’s lifespan and avoid costly downtime.

What Advantages do Tapered Roller Bearings Offer Compared to Other Bearing Types?

Tapered roller bearings offer several advantages that make them a preferred choice in various applications compared to other bearing types. These advantages stem from their unique design and capabilities. Here’s a look at the benefits of tapered roller bearings:

- High Load-Carrying Capacity:

Tapered roller bearings can handle both radial and axial loads simultaneously, making them suitable for applications with combined loads. Their conical geometry allows for effective load distribution, enabling them to support heavy loads without premature wear.

- Efficient Axial Load Handling:

Tapered roller bearings excel at managing axial (thrust) loads in one direction. This capability is crucial in applications where axial loads are present, such as automotive transmissions or industrial machinery.

- Reduced Friction and Heat Generation:

The conical shape of the rollers and the matching raceways result in point contact, reducing friction and minimizing heat generation. This efficiency contributes to improved overall performance and energy savings.

- Adjustable Clearance and Preload:

Tapered roller bearings often allow for adjustable internal clearance or preload. This feature enables fine-tuning of the bearing’s play, optimizing performance and extending the bearing’s lifespan.

- High Precision:

Tapered roller bearings are available in various precision classes to meet different application requirements. Their precision makes them suitable for applications demanding accurate motion control and positioning.

- Versatility:

Tapered roller bearings are used in a wide range of industries and applications, from automotive and heavy machinery to aerospace and industrial equipment. Their ability to handle diverse loads and conditions contributes to their versatility.

- Durability:

Tapered roller bearings are designed to withstand shocks and impacts, making them suitable for applications with dynamic loads or vibrations. Their robust construction contributes to their overall durability.

- High-Speed Capability:

Tapered roller bearings can operate at high speeds due to their efficient contact geometry and reduced friction. This makes them suitable for applications requiring rapid rotation.

- Cost-Effectiveness:

While the initial cost may vary, tapered roller bearings are often cost-effective due to their long service life and ability to handle heavy loads. Their durability can lead to reduced maintenance and replacement costs over time.

- Compatibility with Combined Loads:

Tapered roller bearings are well-suited for applications where radial and axial loads occur simultaneously, eliminating the need for multiple bearing types and simplifying design and installation.

In summary, tapered roller bearings offer a combination of load-carrying capacity, efficiency, adjustability, precision, and versatility that sets them apart from other bearing types. Their ability to handle a variety of loads and conditions makes them an advantageous choice in numerous industrial applications.

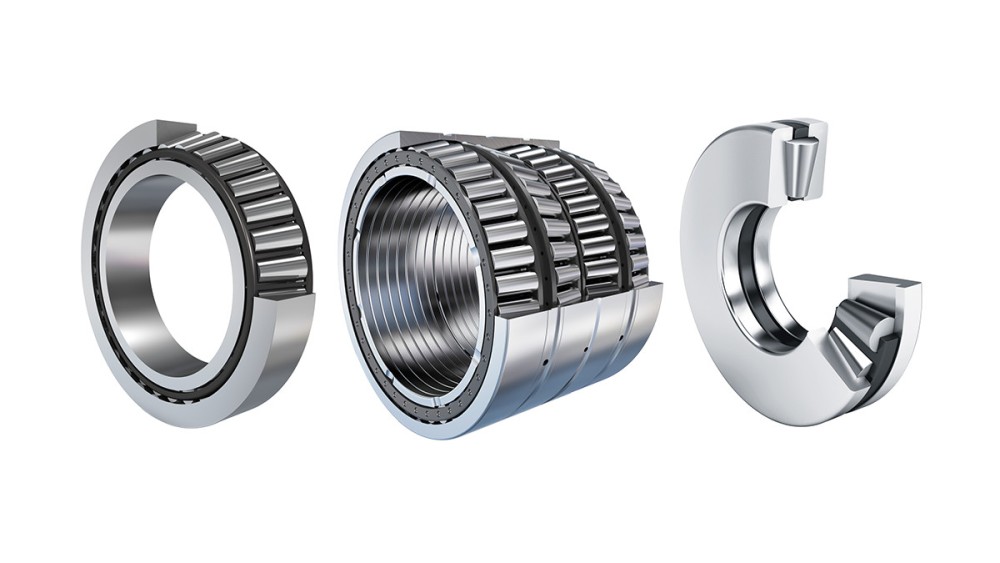

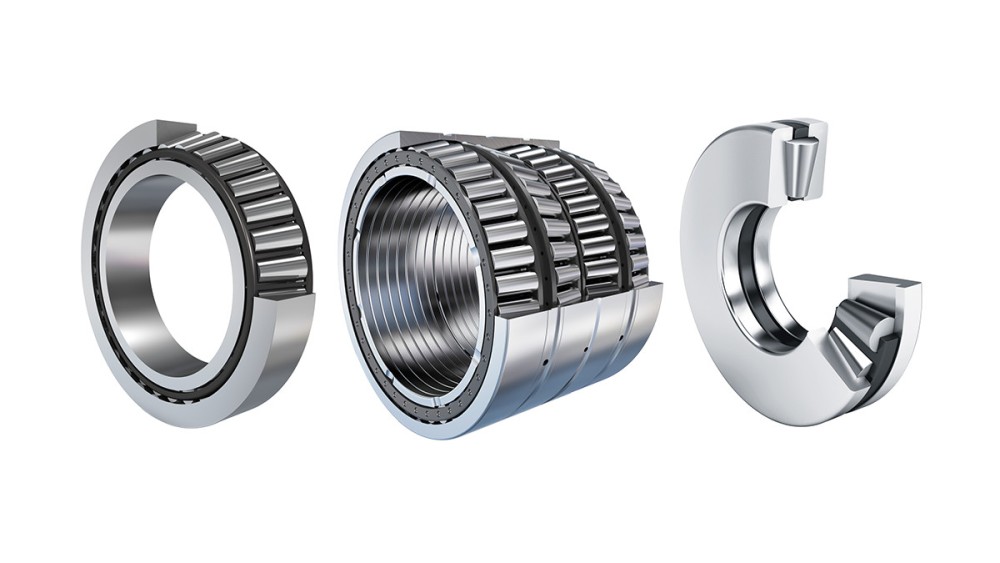

Can you Explain the Design and Construction of Tapered Roller Bearings?

The design and construction of tapered roller bearings are characterized by their conical geometry and specific components that enable them to handle radial and axial loads simultaneously. Here’s an overview of their design and construction:

- Components:

Tapered roller bearings consist of the following components:

- Inner Ring:

The inner ring has a conical raceway on its inner surface, which matches the conical shape of the rollers. It serves as the raceway for the rollers and provides support to the rotating assembly.

- Outer Ring:

The outer ring also features a conical raceway on its inner surface that complements the shape of the rollers. The outer ring provides a rigid structure to house the entire bearing assembly.

- Tapered Rollers:

The rollers have a conical shape with varying diameters along their length. This design allows the rollers to make point contact with the inner and outer raceways, distributing loads efficiently.

- Cage:

The cage or retainer holds the rollers in position, maintaining proper spacing and preventing them from coming into contact with each other. The cage material can vary, and its design may affect factors like friction and heat generation.

- Conical Geometry:

The distinguishing feature of tapered roller bearings is their conical geometry. The conical angle is defined by the contact angle between the roller axis and the bearing axis. This angle facilitates effective load distribution and axial load support.

- Load Distribution:

The conical shape of the rollers and raceways allows tapered roller bearings to handle both radial and axial loads. Radial loads are primarily supported by the larger diameter of the rollers at the large end of the cone, while axial loads are absorbed by the smaller diameter near the small end of the cone.

- Adjustable Clearance and Preload:

Many tapered roller bearings allow for adjustable internal clearance or preload. This feature enables fine-tuning of the bearing’s internal play, optimizing performance and minimizing friction.

- Thrust Capability:

Tapered roller bearings can handle thrust (axial) loads in one direction, making them suitable for applications where axial loads need to be managed along with radial loads.

- Applications:

Tapered roller bearings find applications in various industries, including automotive, heavy machinery, aerospace, and more. They are used in scenarios that require efficient load distribution and handling of combined loads.

In summary, tapered roller bearings are designed with conical geometry to accommodate both radial and axial loads. Their specific components, such as tapered rollers and a cage, work together to ensure effective load distribution, making them suitable for a wide range of industrial applications.

editor by CX 2024-05-08

China OEM Bearing Mr95 Angular Contact Bearings with Deep Groove Ball for Bike/Auto Parts Size 5*9*3mm bearing bronze

Product Description

Detailed Photos:

Product Description

Our precision deep groove ball bearings are designed for high precision, low noise, small vibration, high reliability and long life. They are mainly used in various types of electric motors. They are also known as EMQ (Electric Motor Quality) bearings.

EMQ bearings are widely used in household appliances, toys, electric power tools, car motors and other fields. With optimal design, high reliability heat treatment, precision manufacturing processes and high-grade grease, these products perform better on reliability, vibration and noise levels than standard products making them more suitable for electric motor applications. These products can also be applied to most gearbox applications as well.

| Item | Deep Groove Ball Bearing | Closure type | ZZ/RS |

| OEM ODM | Technical drawing or sample is needed | d(mm) | 5 |

| Original | ZheJiang , China | D(mm) | 9 |

| Material | Chrome steel, Carbon steel, Stainless steel, etc. | B(mm) | 3 |

| Cage Material | Steel / Nylon | Number of row | single |

| Tolerance | P0 P6 P5 P2 P4 | Clearance | C0 C2 C3 C4 |

| Vibration | V1 V2 V3 | Noise | Z1 Z2 Z3 Z4 |

| MOQ | 1000 pcs | Application | Motor/electric/sliding/furniture accessories/ Skateboard/etc. |

| Feature | heavy-duty,adjustable,low noise, easy installation,sliding smoothly,long life,standard,customized,etc | Leading Time | According to the order q’ty |

Company Profile

ABOUT US

Haibite was set up in 1996 and located at HangZhou, a beautiful city in China, covering an area of 16000 square meters. Our company is bearing manufacturer&bearing distributor.

We have own factory that specialize in the production of bearings. We are in a good position to supply you high quality bearing, the finest price and customized service.

Since it was first established, Haibite was dedicated in research, development and manufacture of bearings.

Haibite deep groove ball bearing has numerous technical advantages, such as increased service life of bearing over a broad of operating temperature and all these combined with the highest level of cost effectiveness.

Now, Haibite has become main and 1 of the first grade suppliers of all kinds of bearings. We could develop the products constructed from different materials, structures, shapes, colors etc.

1. Our bearing are in stable quality with smooth rotation, long life operation, small movement, advanced heat treatment etc.

2. The Balls with smooth and long lasting operation, higher performing features like wider adjustment ranges, long rolling life performance, easy installment. It’s adapt in multiple housing choices with any wheels to fit different aluminnum. Our bearing ensure alignment across the full adjustment ranges within built-in retention system.

3. If you need, we also could offer customized hardware service, like plastic parts, stamping patrs, cold forging steel patrs are widely applied in the window and doors, furniture, householders, transmission system, industrial drive system etc.

We are constantly improving and striving for excellent service. We hold a very high regard for our customers, the quality of our products, and our level of customer service.

Packaging & Shipping

Packaging Details

Packaging

A.Polybag +Box+Carton

B.B.Tube+Box+Carton

C.As per customer’s request

We have kinds of packages, such as plastic bags, cartons, special boxes. We use different packages based on the products and our customers’ requirements.

Port :HangZhou

Our Advantages

FAQ

If you have any other questions, please feel free to contact us as follows.

Q: Why did you choose us?

A. We provide the best quality bearings with reasonable price, low friction, low noise and long service life.

B. With sufficient stock and fast delivery, you can choose our freight forwarder or your freight forwarder.

C. The best service provided by a well-trained international sales team.

Q: Do you accept small orders?

100% quality check, once your bearings are standard size bearings, even one, we also accept.

Q: Do you provide samples? Is it free or extra?

Yes, we can provide a small amount of free samples. Do you mind paying the freight?

Q: What should I do if I don’t see the type of bearings I need?

We have too many bearing series numbers. Sometimes we can’t put them all on web. Just send us the inquiry and we will be very happy to send you the bearing details.

Q: What services can we provide?

Accepted Delivery Terms: FOB, CFR, CIF, EXW;

Accepted Payment Currency: USD, EUR, JPY, CNY;

Accepted Payment Type: T/T, L/C, D/P, D/A

Language Spoken: English, Chinese;

Purchase Notice

1. Please send us an inquiry or leave us a message, there will be a dedicated staff to serve you within 1 hours.

2. You can ask us to take actual photos of the products for you, and free samples would be provide.

3. Welcome to visit our factory to negotiate orders, we will do our best to protect the safety of your business journey.

4. Packaging can be customized according to customer requirements.

Finally, please be sure to click “Contact Supplier” to contact us, or “call us” with any questions that you may have.

Welcome to contact me anytime!

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Aligning: | Aligning Bearing |

|---|---|

| Separated: | Unseparated |

| Rows Number: | Single |

| Samples: |

US$ 0.5/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

How does Proper Lubrication Impact the Performance and Longevity of Tapered Roller Bearings?

Proper lubrication is essential for ensuring optimal performance and longevity of tapered roller bearings. Lubrication plays a critical role in reducing friction, preventing wear, and managing heat generated during operation. Here’s how proper lubrication impacts tapered roller bearings:

- Reduced Friction:

Lubrication forms a thin film between the rolling elements and raceways, reducing direct metal-to-metal contact. This minimizes friction and the associated heat generation, allowing the bearing to operate smoothly and efficiently.

- Wear Prevention:

Lubrication forms a protective barrier that prevents wear and surface damage. Without proper lubrication, friction can lead to accelerated wear, pitting, and even surface scoring, shortening the bearing’s lifespan.

- Heat Dissipation:

Effective lubrication helps dissipate heat generated during operation. This is especially crucial in high-speed applications where excessive heat can lead to premature bearing failure or degradation of lubricant properties.

- Corrosion Protection:

Lubrication helps create a barrier that protects bearing surfaces from environmental factors that could lead to corrosion. This is particularly important in applications exposed to moisture, chemicals, or other corrosive agents.

- Noise and Vibration Reduction:

Proper lubrication can dampen vibrations and reduce noise by providing a cushioning effect between the rolling elements and raceways. This contributes to smoother and quieter operation.

- Longevity:

Well-lubricated bearings experience less wear and stress, leading to extended service life. Bearings that are inadequately lubricated or run dry are prone to premature failure due to excessive wear, heat buildup, and damage to bearing surfaces.

- Efficiency:

Adequate lubrication maintains the bearing’s efficiency by minimizing energy losses due to friction. Bearings that lack proper lubrication require more energy to overcome higher friction levels, resulting in reduced efficiency.

- Lubrication Methods:

Various lubrication methods are available, including grease lubrication and oil lubrication. The choice depends on factors such as speed, load, temperature, and application requirements.

To ensure proper lubrication:

- Follow Manufacturer Recommendations:

Consult the bearing manufacturer’s recommendations for lubricant type, viscosity, and replenishment intervals.

- Monitor and Maintain:

Regularly monitor the condition of the lubricant and the bearing’s performance. Implement a maintenance schedule for lubricant replacement or replenishment.

- Environmental Considerations:

Consider the operating environment’s temperature, contamination levels, and exposure to external elements. Some applications may require special lubricants for extreme conditions.

In summary, proper lubrication is crucial for maintaining tapered roller bearings’ performance, preventing wear, reducing friction and heat, and extending their lifespan. A well-lubricated bearing contributes to smoother operation, lower maintenance costs, and improved efficiency.

Can you Explain the Design and Construction of Tapered Roller Bearings?

The design and construction of tapered roller bearings are characterized by their conical geometry and specific components that enable them to handle radial and axial loads simultaneously. Here’s an overview of their design and construction:

- Components:

Tapered roller bearings consist of the following components:

- Inner Ring:

The inner ring has a conical raceway on its inner surface, which matches the conical shape of the rollers. It serves as the raceway for the rollers and provides support to the rotating assembly.

- Outer Ring:

The outer ring also features a conical raceway on its inner surface that complements the shape of the rollers. The outer ring provides a rigid structure to house the entire bearing assembly.

- Tapered Rollers:

The rollers have a conical shape with varying diameters along their length. This design allows the rollers to make point contact with the inner and outer raceways, distributing loads efficiently.

- Cage:

The cage or retainer holds the rollers in position, maintaining proper spacing and preventing them from coming into contact with each other. The cage material can vary, and its design may affect factors like friction and heat generation.

- Conical Geometry:

The distinguishing feature of tapered roller bearings is their conical geometry. The conical angle is defined by the contact angle between the roller axis and the bearing axis. This angle facilitates effective load distribution and axial load support.

- Load Distribution:

The conical shape of the rollers and raceways allows tapered roller bearings to handle both radial and axial loads. Radial loads are primarily supported by the larger diameter of the rollers at the large end of the cone, while axial loads are absorbed by the smaller diameter near the small end of the cone.

- Adjustable Clearance and Preload:

Many tapered roller bearings allow for adjustable internal clearance or preload. This feature enables fine-tuning of the bearing’s internal play, optimizing performance and minimizing friction.

- Thrust Capability:

Tapered roller bearings can handle thrust (axial) loads in one direction, making them suitable for applications where axial loads need to be managed along with radial loads.

- Applications:

Tapered roller bearings find applications in various industries, including automotive, heavy machinery, aerospace, and more. They are used in scenarios that require efficient load distribution and handling of combined loads.

In summary, tapered roller bearings are designed with conical geometry to accommodate both radial and axial loads. Their specific components, such as tapered rollers and a cage, work together to ensure effective load distribution, making them suitable for a wide range of industrial applications.

What are Tapered Roller Bearings and How do They Function in Machinery?

Tapered roller bearings are a type of rolling element bearing designed to handle both radial and axial loads by providing a conical geometry. They consist of inner and outer rings, tapered rollers, and a cage that holds the rollers in place. Tapered roller bearings are commonly used in various machinery and equipment for their ability to support high radial and axial loads simultaneously. Here’s how they function in machinery:

- Geometry:

Tapered roller bearings have an inner ring with a conical surface and an outer ring with a matching conical surface. The rollers are also shaped like truncated cones. This geometry allows the rollers to make contact with both the inner and outer raceways at a common point on the bearing axis, distributing loads more effectively.

- Load Distribution:

The conical shape of tapered rollers enables them to handle both radial and axial loads. Radial loads are supported by the larger diameter of the rollers near the large end of the cone, while axial loads are absorbed by the smaller diameter near the small end of the cone.

- Adjustable Clearance:

Tapered roller bearings often allow for adjustable clearance or preload. This feature permits fine-tuning of the bearing’s internal play to optimize performance, reduce friction, and prevent excessive wear.

- Thrust Capability:

Tapered roller bearings can handle thrust (axial) loads in one direction, making them suitable for applications where axial loads need to be managed along with radial loads.

- Applications:

Tapered roller bearings are commonly used in various machinery and equipment:

- Automotive Industry:

Tapered roller bearings are widely used in wheel hubs, transmissions, and differential systems in automobiles, where they handle radial and axial loads experienced during driving.

- Heavy Machinery:

In construction equipment, mining machinery, and industrial machinery, tapered roller bearings support heavy loads and shocks, making them suitable for applications like earthmoving and material handling.

- Aerospace:

Tapered roller bearings are used in aircraft landing gear, where they support both vertical and horizontal loads during takeoff, landing, and taxiing.

- Railways:

In trains, tapered roller bearings are used in wheelsets and axles to manage radial and axial loads that occur as the train moves along curves and straight tracks.

- Wind Energy:

Tapered roller bearings are employed in wind turbine gearboxes, where they handle the radial and axial loads associated with converting wind energy into electrical power.

- Installation:

Installation of tapered roller bearings often involves adjusting the internal clearance or preload to optimize performance. Proper lubrication is crucial to ensure smooth operation and longevity.

In summary, tapered roller bearings function by utilizing their conical geometry to support both radial and axial loads, making them versatile components in a wide range of machinery and equipment across various industries.

editor by CX 2024-04-23

China Standard Single Row 100*215*47mm Size 7.17kg Weight 7320acm Angular Contact Ball Bearing deep groove ball bearing

Product Description

Product Description

Spherical rollers are put between the spherical raceway on the outer ring and the 2 grooves on the inner ring for there bearings. Since the center of the arc raceway on the outer ring is the same as the center of the whole bearing arrangement, there bearings are self-aligned and automatically adjust the bending of the shaft and housing and the eccentricity. The bearings can carry radial load and axial load in double directions. The especial radial load carrying capability makes there bearings suitable for heavy load and shock load carrying.

Product Parameters

| Product Name | 7320E Angular Contact Ball Bearing |

| Brand Name | RHF or OEM Brand |

| Seals Type | OPEN |

| Material | Chrome Steel ,Stainless steel,Ceramic,Nylon |

| Clearance | C0,C2,C3,C4 |

| Precision Grade | P0,P6,P5,P4,P2(ABEC1, ABEC3, ABEC5, ABEC7, ABEC9) |

| Greese | SRL ,PS2, Alvania R12 ,etc |

| Number of Row | Single Row |

| Package | Box,Carton,Wooden Box,Plastic Tube or Per buyers requirement . |

| MOQ | 1PCS |

| Serice | OEM |

| Sample | Available |

| Payment Term | TT or L/C or Western Union |

Our business:Produce and customize various bearing brands. (Packaging and logo can be customized. All copyright belongs to the customer. We promise not to disclose any information.)

Packaging & Shipping

Company Profile

Exhibitions&Partners

FAQ

Q:Are you trading company or manufacturer?

–We are the company dealing in trading business and manufacturing business.

Q:What’s the MOQ?

–MOQ is 2pcs for standardized products; 300pcs for customized products. There is no MOQ for sample orders.

Q:How long is the lead time?

–The lead time for sample orders is 1-3 days, for bulk orders is generally in 3-15 days.The delivery time is generally in 2 days after payment. It’s according to the order amount.

Q:Do you offer free samples?

–If you place an order, we can return part of sample fee even all of fee to you. It also depends on the quantity of order and the type of sample. And you just need to pay freight.

Q: Could you customized for me?

–Sure,we can supply OEM service as per your drawing or samples.

/* March 10, 2571 17:59:20 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 25° |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

| Samples: |

US$ 0/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do rolling contact bearings perform in high-speed or high-load applications?

Rolling contact bearings are designed to perform effectively in high-speed and high-load applications. Their specific design features and characteristics allow them to withstand the demands and challenges associated with these conditions. Here’s a detailed explanation of how rolling contact bearings perform in high-speed or high-load applications:

- High-Speed Performance:

Rolling contact bearings are well-suited for high-speed applications due to their low friction characteristics. The rolling motion between the rolling elements and the raceways minimizes friction and heat generation, enabling smooth rotation at high speeds. The design of rolling contact bearings, including the selection of suitable materials and precision manufacturing, ensures the balance between load-carrying capacity and reduced friction at high speeds. As a result, these bearings can operate efficiently and reliably in applications such as electric motors, machine tools, turbochargers, and aerospace systems that require rapid and precise rotational motion.

- High-Load Capacity:

Rolling contact bearings are engineered to handle high loads and distribute them effectively. The rolling elements in the bearings, such as balls or rollers, distribute the applied loads over a larger contact area, reducing stress concentrations and preventing premature failure. The materials used in rolling contact bearings, such as high-grade steels and specialized alloys, provide the necessary strength and durability to withstand heavy loads. Additionally, the design of the bearing, including the number and size of the rolling elements, the geometry of the raceways, and the cage construction, is optimized to maximize load-carrying capacity. This enables rolling contact bearings to perform reliably in high-load applications, including heavy machinery, automotive drivetrains, construction equipment, and industrial processes.

- Lubrication for High-Speed and High-Load Conditions:

Lubrication is crucial for the performance of rolling contact bearings in high-speed or high-load applications. The lubricant helps reduce friction, dissipate heat, and prevent wear and damage to the bearing surfaces. For high-speed applications, specialized lubricants with low viscosity and high thermal stability are often used to ensure efficient lubrication and prevent excessive heat buildup. In high-load applications, lubrication plays a vital role in load distribution and reducing the risk of premature failure due to excessive stress. Proper lubrication selection and maintenance are essential to ensure optimal performance and longevity of rolling contact bearings under high-speed or high-load conditions.

- Preload and Stiffness:

In certain high-speed or high-load applications, rolling contact bearings may be preloaded to enhance their stiffness and improve their performance. Preload is a controlled axial force applied to the bearing that eliminates internal clearances and minimizes deflection under load. By applying preload, the rolling contact bearings can maintain their dimensional stability, minimize vibration, and enhance their ability to handle high-speed or high-load conditions. Preload is commonly utilized in precision machine tools, spindle bearings, and other applications where rotational accuracy and rigidity are critical.

In summary, rolling contact bearings perform exceptionally well in high-speed or high-load applications. They are designed to minimize friction, handle heavy loads, and maintain operational integrity under demanding conditions. Through their low friction characteristics, high-load capacity, appropriate lubrication, and potential use of preload, rolling contact bearings ensure reliable and efficient operation in various industries and applications requiring high-speed or high-load capabilities.

Can you provide guidance on the selection and sizing of rolling contact bearings for specific applications?

Yes, I can provide guidance on the selection and sizing of rolling contact bearings for specific applications. Choosing the right rolling contact bearings involves considering various factors such as load requirements, operating conditions, speed, and environmental factors. Here’s a detailed explanation of the steps involved in selecting and sizing rolling contact bearings:

- Identify Application Requirements:

Start by identifying the specific requirements of your application. Consider factors such as the type and magnitude of the loads the bearing will be subjected to, the operating speed, and any special environmental conditions like temperature, moisture, or exposure to corrosive substances. Understanding these requirements is crucial as it forms the basis for selecting the appropriate rolling contact bearing.

- Analyze Load Conditions:

Next, analyze the load conditions acting on the bearing. Determine if the load is radial, axial, or a combination of both. Consider factors such as the magnitude, direction, and frequency of the load. This analysis helps in determining the appropriate bearing type, such as deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings, or tapered roller bearings, that can handle the specific load conditions effectively.

- Calculate Equivalent Load:

Calculate the equivalent load acting on the bearing. In cases where the load acting on the bearing is a combination of radial and axial loads, it is necessary to calculate the equivalent load. The equivalent load accounts for the differing effects of radial and axial loads on the bearing and helps in determining the required bearing size and capacity.

- Consider Speed and Operating Conditions:

Take into account the speed at which the bearing will operate and the specific operating conditions. Higher speeds may require bearings with special design features or materials to handle the increased centrifugal forces and temperature rise. Consider factors such as lubrication requirements, temperature limits, and any special considerations for factors like shock loads, vibrations, or misalignment. These factors influence the selection of appropriate bearing types and configurations.

- Consult Bearing Manufacturer’s Catalogs:

Refer to the catalogs or technical specifications provided by bearing manufacturers. These catalogs contain detailed information about various bearing types, sizes, load ratings, and performance characteristics. Use the information provided to narrow down the options based on your application requirements and load calculations.

- Verify Bearing Life:

Check the calculated bearing life to ensure it meets the required operational lifespan of your application. Bearing manufacturers provide life calculation formulas based on industry standards such as ISO or ABMA. These formulas take into account factors like load, speed, and reliability requirements to estimate the expected bearing life. Verify that the selected bearing will provide the desired operational lifespan under the given operating conditions.

- Consider Mounting and Dismounting:

Lastly, consider the ease of mounting and dismounting the bearing in your specific application. Evaluate factors such as the bearing’s fit tolerance, the required clearance or preload, and any special mounting or dismounting procedures. Ensure that the selected bearing can be easily installed and maintained in your application.

It is important to note that the selection and sizing of rolling contact bearings can be complex, and it is advisable to seek the assistance of bearing manufacturers, engineers, or experts in the field to ensure the optimal selection for your specific application.

Can you describe the load-carrying capacity and load ratings of rolling contact bearings?

Rolling contact bearings are designed to carry various types of loads in mechanical systems. The load-carrying capacity and load ratings of rolling contact bearings play a crucial role in determining their suitability for specific applications. Here’s a detailed explanation of these concepts:

- Load-Carrying Capacity:

The load-carrying capacity of a rolling contact bearing refers to its ability to support and distribute loads without excessive deformation or failure. It is influenced by factors such as the bearing’s design, material properties, and operating conditions. Rolling contact bearings are primarily designed to carry two types of loads:

- Radial Loads: Radial loads act perpendicular to the axis of rotation and are supported by the bearing’s raceways. Radial loads can arise from the weight of the shaft, centrifugal forces, or external forces applied to the bearing. The load-carrying capacity for radial loads is typically specified by the maximum radial load the bearing can withstand without suffering permanent deformation or reduced performance.

- Axial Loads: Axial loads act parallel to the axis of rotation and are supported by the bearing’s configuration, such as the arrangement of the rolling elements or the presence of thrust surfaces. Axial loads can arise from forces that push or pull along the axis of rotation. The load-carrying capacity for axial loads is typically specified by the maximum axial load the bearing can withstand without experiencing excessive wear or reduced performance.

It’s important to note that the load-carrying capacity of a rolling contact bearing is influenced by factors such as rotational speed, lubrication, temperature, and operating conditions. These factors can affect the performance and durability of the bearing under different load conditions.

- Load Ratings:

Load ratings provide standardized values that indicate the maximum permissible loads a rolling contact bearing can carry under specific operating conditions. These ratings help engineers and designers select bearings that can withstand the expected loads in a given application. The two primary load ratings specified for rolling contact bearings are:

- Dynamic Load Rating: The dynamic load rating (C) represents the maximum load that a bearing can carry for a specified number of revolutions or operating hours without developing excessive wear or fatigue. It is based on the bearing’s ability to withstand rolling contact fatigue, which is the most common mode of failure in rolling contact bearings. The dynamic load rating is typically provided by the bearing manufacturer and is expressed in units of force (such as Newtons or pounds-force).

- Static Load Rating: The static load rating (Co) indicates the maximum load that a bearing can withstand without permanent deformation when the bearing is stationary or subjected to very slow rotational speeds. It represents the load capacity of the bearing under static or slowly changing loads. Similar to the dynamic load rating, the static load rating is also provided by the bearing manufacturer and expressed in units of force.

It’s important to consider both the dynamic and static load ratings when selecting a rolling contact bearing for an application. The dynamic load rating is crucial for assessing the bearing’s ability to withstand the varying loads during operation, while the static load rating provides information about the bearing’s resistance to deformation under stationary or slow-speed conditions.

By considering the load-carrying capacity and load ratings of rolling contact bearings, engineers can choose the appropriate bearing type and size to ensure reliable and efficient operation in their specific applications.

editor by CX 2024-02-18

China supplier Hot Sale for Wholesale Engine Part Crankshaft Pads Main Bearing Sets Tiles Connecting Conrod Bearings Oversize / Std Size R043A for CZPT carrier bearing

Product Description

Product Description

|

Type |

Engine Main Baering |

|

Filter Size |

Standard Size |

| Quality | Original / Aftermarket Replacement |

|

Materials |

Aluminum / Copper |

|

Service |

OEM & ODM |

|

Supply Ability |

1000000 sets / Week |

|

FOR Port |

HangZhou/HangZhou/ZheJiang /HangZhou |

|

Packing |

RAINBOW brand /Neutral/Customized/Color box/ same like original package |

Various Engine Parts

Connecting Rod Bearing:

Toyota:

1A,2A,3A,7A-FE,1AZ,2AZ,3B,11B,14B,15B,1C,2C,3C,1E,2E,4E,1FZ-FE,1GR-FE,2GR-FE,1HZ,1HD,1KD,2KD,1KZ,L,2L,

3L,5L,20R,21R,22R,1RZ,2RZ,3RZ,2TZ-FE,1S,2S,3S,1SZ-FE,1TR-FE,2TR-FE,1Y,2Y,3Y,4Y

Main Bearing:M571A,MS-1400A,M043A,MS-1401A,M043A,MS-1401A,M724A,MS-1454A,M040A,MS-1428A,M038A,

MS-1408A,M045A,MS-1421A,M717A,MS-1448A,M571A,MS-1415A,M708A1,MS-1438A,M736A,M738A,MS-1458A,

M707A,MS-1436A,M720A1,MS-1452A,M042A1,MS-1406A,M011H,MS-1133GP,M571H,MS-1405GP,M703A2,MS-1435A,

M571A,MS-1404A,M725A,MS-1450A,M729A,MS-1459A,M041A,MS-1407A,M715A,MS-1457A

Con-rod Bearing:R571A,CB-1400A,R714A,CB-1400A,R724A,CB-1454A,R048A1,CB-1429A,R038A,CB-1408A,R045A,

CB-1421A,R717A,CB-1448A,R718A,CB-1453A,R571A,CB-1415A,R708A,CB-1438A,R736A,R738A,CB-1458A,R707A,

CB-1436A,R720A1,CB-1452A,R037A,CB-1406A,R039A,CB-1411A,R571A,CB-1404A,R725A,CB-1450A,R729A,CB-1459A,

R041A,CB-1407A,R715A,CB-1457A

Nissan:

CA16,CA18,CA20,CD20,E10,E13,E15,E16,GA13,GA15,GA16,KA24,L13,L14,L16,L18,

L24,L26,L28,LD28,L20B,LD20,Z22,Z24,MA09,MA10,RD28,SR18,SR20,VG30E,VG33E,Z16,Z18,BD30

,ED33,FD33,ED35,PD6,PE6,QD32,SD20,SD22,SD23,SD25,TD25,TD27,TD42

Main Bearing:M083H,MS-1173GP,M068H,MS-1174GP,M094A,MS-1208A,M084H,MS-1209GP,

M054H,MS-1043GP,M057H,MS-1047GP,M066H2,MS-1183GP,M093A,MS-1202A,M097A,MS-1207A,

M098H,MS-1213GP,M088H,MS-1211GP,M054H,MS-1043GP,M087H,MS-1190GP,M082H,MS-1180GP,

M076H1,MS-1084GP,M087H,MS-1190GP,M085H,MS-1182GP,M087H,M096H,MS-1190GP

Con-rod Bearing:R083H,CB-1173GP,R095A,CB-1217A,R068H,CB-1174GP,R094A,CB-1208A,R084H,

CB-1209GP,R054H1,CB-1044GP,R057H,CB-1047GP,R054H1,CB-1044GP,R093A,CB-1202A,R097A,

CB-1207A,R098H,CB-1213GP,R088H,CB-1210GP,R054H1,CB-1044GP,R089H,CB-1190GP,R082H1,

CB-2801GP,R076H1,CB-1084GP,R089H,CB-1190GP,R080H1,CB-1571GP,R089H,CB-1190GP,R096H,CB-1190GP

Mitsubishi:

4G13,4G15,G13B,G15B,4G30,4G32,4G33,4G37,4G52,4D55,4D56,4G63,4G64,4G91,

4G92,4G93,6G71,6G72,6G74,4D65,4M40,4D30,4D31,4D32,4D33,4D34,4D35,6D10,6D11,6D14,6D15,

6D14-T,6D15-T,6D16,6D31,8DC9,8DC10,8DC11,4M50,4M51,K4N,K4E,S4L,S4S,S6S,S4K,S6K,S3E,S4E

Main Bearing:M119A,MS-1818A,M111A2,MS-1821A,M113A3,MS-1131A,M136A,MS-1827A,M135A,MS-1828A,

M123A1,MS-1822A,M138H,MS-1842A,M111A2,MS-1821A,M133H,MS-1832GP,M121H,MS-1807GP,M121H,

MS-1807GP,M112H2,MS-1145GP,M112H2,MS-1145GP,M132H,MS-1808GP,MP107H3,M1-1147GP,M144H,MS-1836GP,

M623A,M623A,MP126A,M1-1843A,MP131H,M1-1833A,MP128H,M1-1826GP

Con-rod Bearing:R119A,CB-1169A,R130A,CB-1825A,R111A,CB-1085A,R113A1,CB-1131A,R136A,

CB-1827A,R135A,CB-1828A,R123A,CB-1822A,R138H,CB-1842A,R111A,CB-1085A,R133H,R121H,CB-1807GP,

R122H,CB-1830GP,R112H1,CB-1820GP,R132H,CB-1808GP,R124H1,CB-1804GP,R144H,CB-1835GP,R145H,CB-1836P,R622A,

R623A,RP126A,C1-1843A,RP131H,C1-1833A,RP128H,C1-1826GP

Suzuki:

F8A,F10A,F8B,Y64,F5A,F6A,G10,G13,G15,G16,SWIFT,INDIA,H20A,H25A

Main Bearing:M651A,MS-1179A,M654A,MS-2401A,M653A,MS-2402A,M658A,MS-2406A,M655A,MS-2403A,

M656A,MS-2404A,M657A,MS-2405A,M5930A,M662A,R662A,CB-2407A,R662A,CB-2407A

Con-rod Bearing:R651A,CB-1179A,R652A,CB-2401A,R653A,CB-2402A,R658A,CB-2406A,R655A,

CB-2403A,R656A,CB-2404A,R657A,CB-2405A,R5930A,MS-2409A,M663A,MS-2407A

Isuzu:

4JA1,4JC1,4JD1,4JB1,4JH1,4HF1,4HG1,4HK1,6HE1,6HH1,6HK1,4BD1,4BG1,6BD1,

6BF1,6BG1,C190,C223,C221,C240

Main Bearing:M184A1,MS-1622GP,M185A,MS-1623GP,M801H,MS-1631GP,M802H,MS-1632GP,M190H,

MS-1604GP,M182H1,MS-1612GP,M183H,MS-1605GP,M160H2,MS-1610GP

Con-rod Bearing:CB-1622GP,R184A1,R184A1,CB-1622GP,R801H,CB-1631GP,R808H,CB-1640GP,

R802H,CB-1621GP,R809H,CB-1639GP,R168H,CB-1603GP,R169H1,CB-1612GP,R160H,CB-1070GP

Hino:

EF550,EF750,EH500,EH700,EK100,EL100,EM100,H06C,H07C,H07D,J05C,J08C,J05D,

J08D,W04D,W06D

Main Bearing:M220H1,MS-2107GP,M208H1,MS-1140GP,M214H,MS-2102GP,M215H,MS-2103GP,M215H,

MS-2103GP,M218H1,MS-2108GP,M218H1,MS-2108GP,MP224H,M1-2117GP,MP224H,M1-2117GP,

MS-2109GP,M217H,MS-2109GP

Con-rod Bearing:R220H1,CB-2107GP,R214H,CB-2102GP,R215H,CB-2103GP,R223H,CB-2106GP,

R218H1,CB-2111GP,R224H1,CB-2115GP,RP224H1,C1-2117GP,RP226H,CB-2109FP,R217H,CB-2109FP

Mazda:

B1,B3,B5,B6,E1/3/5,UC,TC,F6,F8,WL,W9,WE,HA,SL,T3500,S2,E2200,MA,VB,B2000,

NA,B1600,E1600,R2,RF

Main Bearing:M313A,MS-2008A,M317A,MS-2012A,M313A,MS-2008A,M315A,MS-2004A,M327A,MS-2016A,

M312A,MS-1153GP,M314H,MS-1181GP,M304A,MS-1114A,M304A,MS-1114A,M316A,MS-2007A

Con-rod Bearing:R313A,CB-1168A,R317A,CB-2008A,R313A,CB-1168A,R336A,CB-2004A,R327A,

CB-2016A,R322A,CB-2571A,R312A,CB-1153GP,R314H,CB-1181GP,R305A,CB-1086A,R304A1,

CB-1141A,R315A1,CB-2007A,R336A,CB-2004A

HYUNDAI&KIA:

G4AJ,G4DJ,4G15,G4CN,4G63,G4EK,G4HC,ATOS,VVT,G4FC,G4KE,G4NC,D4EA,D4B,

H100,D4FA,B3,B5,HW,J2,JT

Main Bearing:21571-2112,M3101A,21571-32830,M3102A,21571-26040,M3105A,21571-57140,21571-2B000,

M3108A,21571-2G000,M3109A,21571-2E000,21571-27900,M3107A,23571-42030,M113A,21571-2A900,

KK1Y0-11-SG0,M3001A,0K7Y0-11-SG0,0K6Z2-11-SG0,M3003A

Con-rod Bearing:23060-2112,R3101A,23060-32030,R3102A,23060-26040,R3105A,M3106A,

23060-57100,R3106A,23060-2B001,R3108A,23060-2G100,R3109A,23060-2E000,23060-27900,

R3107A,23611-42000,R113A,23060-2A901,KK1Y0-11-SE0,R3001A,M3004A,R3004A,0K7Y0-11-SE0,

Company Profile

Packaging & Shipping

Certifications

FAQ

Q1.Could you tell me the material of our bearing?

A:We have Aluminum, Copper.

Q2. What is your terms of packing?

A: Generally, we pack our goods in Neutral Blister. If you have legally registered patent, we can pack the goods in your brand after getting your authorization letters.

Q3. What is your terms of payment?

A: T/T 30% as deposit, and 70% before delivery. We’ll show you the photos of the products and packages before you pay the balance.

Q4. How about your delivery time?

A: Generally, it will take 30 to 60 days after receiving your advance payment. The specific delivery time depends on the items and the quantity of your order.

Q5. Can you produce according to the samples?

A: Yes, we can produce by your samples or technical drawings. We can build the molds.

Q6. What is your sample policy?

A: We can supply the sample if we have ready parts in stock, but the customers have to pay the sample cost and the courier cost.

Q7. Do you test all your goods before delivery?

A: Yes, we have 100% test before delivery.

Q8: What is your terms of delivery?

A: A: EXW, FOB, CFR, CIF.

Q9: Do you accept OEM&ODM?

A: Yes, we accept.

Q10: How do you guarantee the quality of the product?

A: Our factory has established a comprehensive testing mechanism, and every step of the production has undergone a strict quality inspection.

Our product quality matches our price and has been distributed to customers all over the world in the past 10 years, with no complaint from customers. If there is any quality problem, our company will be responsible to the end.

|

Shipping Cost:

Estimated freight per unit. |

To be negotiated |

|---|

| Certification: | CCC, COP, ISO9001, CE, RoHS, TS16949 |

|---|---|

| Standard Component: | Standard Component |

| Technics: | Press |

| Customization: |

Available

| Customized Request |

|---|

Advantages of Ball Bearings

What is a ball bearing? A ball bearing is a type of rolling-element bearing that utilizes balls to maintain separation between two bearing races. Its contact angle between the balls and the races helps it reduce friction between the loads. There are several advantages to ball bearings, including their ability to withstand water. Read on to learn more. Here are a few of the benefits. You can use them in your daily life, from your car to your boat.

Ball bearings reduce friction between loads

Ball bearings reduce friction between loads by constraining the relative motion between moving parts. These bearings consist of a ring of small metal balls that reduce friction between moving objects. The name “ball bearing” is derived from the verb “to bear.” The lubricant within the bearing reduces friction between moving particles. In a machine, ball bearings reduce friction between moving parts and improve linear motion around a fixed axis.

These bearings are commonly used to reduce friction between loads in rotating machines. They have two tracks, one fixed to the rotating part and one stationary. The rolling balls of a ball bearing have lower friction than flat surfaces. Because of this, they are useful for bar stool bearings. They reduce friction between surfaces and maintain the separation between bearing races. Hence, minimal surface contact is possible. Ball bearings have the potential to increase the life of machines and reduce energy consumption.

Ball bearings can be as small as a wrist watch or as large as an industrial motor. They function the same way, reducing friction between loads. Among their many uses, ball bearings are essential for everyday operations. Clocks, air conditioners, fans, and automobile axles all use ball bearings. In fact, anything that uses a motor requires ball bearings. It’s no wonder they’re gaining popularity in industries and everyday life.

They support radial and axial loads

Radial ball bearings are used primarily for radial loads, but they also have a capacity for axial load. This load capacity is usually given as a percentage of the radial load rating. Axial load capacity is generally greater for a bearing with a larger difference between the inner and outer ring diameters. The axial load capacity is also affected by the bearing’s raceway depth, with shallow raceways being more suitable for heavier axial loads.

The two main types of axial and radial loads are defined by their orientation. Axial loads apply forces in one direction while radial loads act on the opposite direction. In both cases, the bearing must support the forces that are imposed. Axial loads apply forces to a bearing in a single direction, while radial loads apply forces in both directions. Regardless of the type of load, axial and radial loads should be considered when selecting a bearing for a given application.

Angular and radial ball bearings differ in their materials. Radial ball bearings are made largely of through-hardened materials. They typically have a Rockwell hardness rating of 58 Rc. The raceways and balls of these bearings are made of 440C stainless steel. They may also contain shields and seals. SAE 52100 steel is the most common material for the raceway, while molybdenum steels are excellent for high temperatures.

They have a contact angle between the balls and the races

When comparing axial load bearings with their radial counterparts, the angular contact angle is more important. Axial load bearings, have a contact angle between the balls and the races of 35 degrees. They are suitable for axial loads and a limited radial load. The contact angle of these bearings is a result of the shape of the inner and outer rings. Each rolling element comes into contact with the inner and outer rings only at one point, forming a 30 degree angle with the radial plane. The radial force of the axial load on these bearings is therefore increased by increasing the contact angle between the balls and the races.

This contact angle determines the amount of friction between the balls and the races, and allows angular contact bearings to withstand heavy radial and thrust loads. In addition, the larger the contact angle, the greater the axial load support. Angular contact bearings come in standard imperial (inch) and metric (mm) sizes. The angular contact angle is determined by the free radial play value and the curvature of the inner track.

They are water-resistant

In addition to their water-resistant qualities, corrosion-resistant ball bearings can also protect against the damaging effects of corrosive environments. Generally, standard metals, such as steel, are susceptible to rust, which can significantly reduce their performance and extend the life of parts. However, plastics, stainless steel, and ceramics can provide corrosion-resistant ball bearings. And because these materials are much more durable, they offer other advantages, such as being easy to maintain.

Among the advantages of plastic ball bearings is their high resistance to extreme temperatures, high speeds, and corrosion. Depending on their construction, plastic bearings are often able to resist corrosion and anti-static properties. They’re lightweight and inexpensive compared to steel ball bearings. CZPT Sales Corporation was established in 1987 with a modest turnover of four lacs. As of the last financial year, it has grown to 500 lacs in sales.

Other advantages of water-resistant ball bearings include corrosion resistance, which is a key consideration in many applications. While stainless steel is highly corrosion-resistant, it decreases the bearing’s load-carrying capacity. Also, corrosion-resistant deep groove ball bearings are usually made with a specified internal clearance, which absorbs loss in clearance during mounting and shaft expansion. This factor affects their performance, and if these are compromised, a replacement may be necessary.

They are tough

A few things make ball bearings tough: they’re made of real materials, which means that they have inherent imperfections. Grade-1 balls are made especially for high-stress applications, such as Formula One engines. Grade-3 balls, on the other hand, strike the perfect balance between performance and cost. Ceramic balls, for example, are made to spin at a high rate of 400 RPM, and they’re finished with a mirror finish.

A steel carbon ball bearing is one of the toughest forms of ball bearings available. The material is incredibly strong, but the contact between the balls isn’t the best. Low-carbon steel is best for linear shafting and is usually coated with a polymer to prevent damage. Steel ball bearings with moderate amounts of carbon are tough, durable, and water-resistant. They’re ideal for gears, but their high-carbon steel counterparts are particularly tough and can resist corrosion.

A ceramic ball bearing is another option. This type has steel inner and outer rings but ceramic balls. Ceramic balls can withstand higher temperatures than steel and are also electrically insulating. Ceramic ball bearings also tend to be lighter and are more resistant to wear and tear. They’re also ideal for applications in which grease is not an option, such as in space shuttles. Despite the fact that ceramic ball bearings are tough, they’re still cheaper than steel ball bearings.

They are conductive

You may have heard the term “ball bearing” if you’ve studied introductory physics. What does that mean? Essentially, ball bearings are conductive because of their ability to conduct electricity. This ability is reflected in the charge distribution on the surface of the ball. Positive charges are drawn toward the positive plate, while negative charges are drawn away from the positively charged ball bearing. You may have even seen a ball bearing in action.

However, despite their conductive nature, ball bearings can still become damaged by electrical discharge. A higher voltage can cause the balls to pit, and the raceways to become uneven. These uneven surfaces will first show up as excessive noise, and eventually cause the bearing to malfunction. Fortunately, engineers have found a way to counter this problem: conductive grease. This grease enables current to flow through the ball bearing, preventing both heat and voltage buildup.

The difference between steel and ceramic ball bearings is their density. Steel bearings are more conductive than glass or hybrid ceramics. Steel ball bearings have an even grain structure and are conductive for resonance flow. When moving fast, the air surrounding the steel ball bearing carries resonance from the inner ring to the outer. This makes them ideal for high-speed resonance transfer. In addition to being conductive, glass microbeads are harder and lighter than steel.

They are used in pulley systems

Pulley systems use ball bearings to move the sprocket, which is a wheel that rotates. These bearings are installed on the center mounting hole of the pulley wheel. They protect the entire system from heat, while allowing higher speed and smooth operation. They distribute the weight of the load evenly, minimizing friction and wobbling, and ensure a smooth rotation. Ball bearings are typically made from steel and are installed inside the pulley wheel.

The moment of inertia and bearing friction are measured to within ten percent accuracy. These two variables affect the speed of the pulley system, which can lead to crashes if the weight holders are not balanced. Therefore, ball bearings are used to minimize the chance of such crashes. When you want to know more about ball bearings in pulley systems, here are the advantages they provide.

Another benefit of ball bearings in pulley systems is that they have lower friction than their solid counterparts. In order to reduce friction, however, ball bearings must be made of good materials. Some of the common ball materials are high-quality plastics and stainless steel. Good materials and clever block design are essential to minimizing friction. If you are planning to use ball bearings in your pulley system, check out the following tips and make sure you are choosing the right one for your application.

editor by CX 2023-06-12

China Wheel Bearing Wheel Hub Bearing Hub Bearing Auto Bearing 566719 Size 56*67*19mm with High Precision Low Noise Factory Price with high quality

Solution Description

Product Description

| Car Design | ALL |

| OEM | Available |

| hub bearing variety | wheel bearing |

| Material | Steel |

| Warranty | 1 Calendar year |

| Brand Name | penso |

| Clearance | C0,C2,C3 |

ABOUT US

HangZhou Pengshuo Imp&Exp Trade(manufacturing unit) Co., LTD, is a factory specialized in bearings, specifically Wheel Bearings, Deep Groove Ball Bearings, Cylindrical Roller Bearings and so on. We focus in this discipline for 15 years, with the power of productions and detection products, higher-high quality engineering technical staff, and employees.

We also specialize in Imp&Exp for 6 years. We experienced company in Nigeria, to market our personal bearing brand name”LION”.Our items experienced adopted ISO9001:2000 Quality System Authorities.

For a lot more information, we’d like you to browse the attachment below.

FAQ

1. How can I get the price?

-We usually quote inside 24 several hours soon after we get your inquiry(Besides weekend and holiday seasons). If you are very urgent to get the value, you should email us or make contact with us in other methods so that we can offer you you a quote.

two. Can I buy samples putting orders?

-Indeed. Make sure you truly feel free of charge to contact us.

3. What is your guide time?

-It relies upon on the purchase amount and the season you place the buy.

Usually, we can ship inside 7-15 times for modest quantity and about 30 days for massive quantity.

4. What is your payment expression?

-T/T, Western Union, MoneyGram, and Paypal. This is negotiable.

5. What is the transport strategy?

-It could be delivered by sea, by air or by specific(EMS, UPS, DHL, TNT, FEDEX and etc). Remember to validate with us before putting orders.

6. How do you make our business extended-time period and a good partnership?

-a. We hold good good quality and competitive price tag to ensure our consumers reward

-b. We regard every customer as our buddy and we sincerely do business and make close friends with them, no subject the place they arrive from.

| After-sales Service: | Best Service |

|---|---|

| Warranty: | 1 Year |

| Type: | Wheel Hub Bearing |

| Material: | Chrome Steel |

| Tolerance: | P0 |

| Certification: | ISO9001, TS16949, ISO9006, QS9000, VDA6.1 |

###

| Samples: |

US$ 3/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

|---|

###

| Car Model | ALL |

| OEM | Available |

| hub bearing type | wheel bearing |

| Material | Steel |

| Warranty | 1 Year |

| Brand Name | penso |

| Clearance | C0,C2,C3 |

| After-sales Service: | Best Service |

|---|---|

| Warranty: | 1 Year |

| Type: | Wheel Hub Bearing |

| Material: | Chrome Steel |

| Tolerance: | P0 |

| Certification: | ISO9001, TS16949, ISO9006, QS9000, VDA6.1 |

###

| Samples: |

US$ 3/Piece

1 Piece(Min.Order) |

|---|

###

| Customization: |

|---|

###

| Car Model | ALL |

| OEM | Available |

| hub bearing type | wheel bearing |

| Material | Steel |

| Warranty | 1 Year |

| Brand Name | penso |

| Clearance | C0,C2,C3 |

Advantages of Ball Bearings

What is a ball bearing? A ball bearing is a type of rolling-element bearing that utilizes balls to maintain separation between two bearing races. Its contact angle between the balls and the races helps it reduce friction between the loads. There are several advantages to ball bearings, including their ability to withstand water. Read on to learn more. Here are a few of the benefits. You can use them in your daily life, from your car to your boat.

Ball bearings reduce friction between loads

Ball bearings reduce friction between loads by constraining the relative motion between moving parts. These bearings consist of a ring of small metal balls that reduce friction between moving objects. The name “ball bearing” is derived from the verb “to bear.” The lubricant within the bearing reduces friction between moving particles. In a machine, ball bearings reduce friction between moving parts and improve linear motion around a fixed axis.

These bearings are commonly used to reduce friction between loads in rotating machines. They have two tracks, one fixed to the rotating part and one stationary. The rolling balls of a ball bearing have lower friction than flat surfaces. Because of this, they are useful for bar stool bearings. They reduce friction between surfaces and maintain the separation between bearing races. Hence, minimal surface contact is possible. Ball bearings have the potential to increase the life of machines and reduce energy consumption.

Ball bearings can be as small as a wrist watch or as large as an industrial motor. They function the same way, reducing friction between loads. Among their many uses, ball bearings are essential for everyday operations. Clocks, air conditioners, fans, and automobile axles all use ball bearings. In fact, anything that uses a motor requires ball bearings. It’s no wonder they’re gaining popularity in industries and everyday life.

They support radial and axial loads

Radial ball bearings are used primarily for radial loads, but they also have a capacity for axial load. This load capacity is usually given as a percentage of the radial load rating. Axial load capacity is generally greater for a bearing with a larger difference between the inner and outer ring diameters. The axial load capacity is also affected by the bearing’s raceway depth, with shallow raceways being more suitable for heavier axial loads.

The two main types of axial and radial loads are defined by their orientation. Axial loads apply forces in one direction while radial loads act on the opposite direction. In both cases, the bearing must support the forces that are imposed. Axial loads apply forces to a bearing in a single direction, while radial loads apply forces in both directions. Regardless of the type of load, axial and radial loads should be considered when selecting a bearing for a given application.

Angular and radial ball bearings differ in their materials. Radial ball bearings are made largely of through-hardened materials. They typically have a Rockwell hardness rating of 58 Rc. The raceways and balls of these bearings are made of 440C stainless steel. They may also contain shields and seals. SAE 52100 steel is the most common material for the raceway, while molybdenum steels are excellent for high temperatures.

They have a contact angle between the balls and the races

When comparing axial load bearings with their radial counterparts, the angular contact angle is more important. Axial load bearings, have a contact angle between the balls and the races of 35 degrees. They are suitable for axial loads and a limited radial load. The contact angle of these bearings is a result of the shape of the inner and outer rings. Each rolling element comes into contact with the inner and outer rings only at one point, forming a 30 degree angle with the radial plane. The radial force of the axial load on these bearings is therefore increased by increasing the contact angle between the balls and the races.

This contact angle determines the amount of friction between the balls and the races, and allows angular contact bearings to withstand heavy radial and thrust loads. In addition, the larger the contact angle, the greater the axial load support. Angular contact bearings come in standard imperial (inch) and metric (mm) sizes. The angular contact angle is determined by the free radial play value and the curvature of the inner track.

They are water-resistant

In addition to their water-resistant qualities, corrosion-resistant ball bearings can also protect against the damaging effects of corrosive environments. Generally, standard metals, such as steel, are susceptible to rust, which can significantly reduce their performance and extend the life of parts. However, plastics, stainless steel, and ceramics can provide corrosion-resistant ball bearings. And because these materials are much more durable, they offer other advantages, such as being easy to maintain.

Among the advantages of plastic ball bearings is their high resistance to extreme temperatures, high speeds, and corrosion. Depending on their construction, plastic bearings are often able to resist corrosion and anti-static properties. They’re lightweight and inexpensive compared to steel ball bearings. CZPT Sales Corporation was established in 1987 with a modest turnover of four lacs. As of the last financial year, it has grown to 500 lacs in sales.

Other advantages of water-resistant ball bearings include corrosion resistance, which is a key consideration in many applications. While stainless steel is highly corrosion-resistant, it decreases the bearing’s load-carrying capacity. Also, corrosion-resistant deep groove ball bearings are usually made with a specified internal clearance, which absorbs loss in clearance during mounting and shaft expansion. This factor affects their performance, and if these are compromised, a replacement may be necessary.

They are tough

A few things make ball bearings tough: they’re made of real materials, which means that they have inherent imperfections. Grade-1 balls are made especially for high-stress applications, such as Formula One engines. Grade-3 balls, on the other hand, strike the perfect balance between performance and cost. Ceramic balls, for example, are made to spin at a high rate of 400 RPM, and they’re finished with a mirror finish.

A steel carbon ball bearing is one of the toughest forms of ball bearings available. The material is incredibly strong, but the contact between the balls isn’t the best. Low-carbon steel is best for linear shafting and is usually coated with a polymer to prevent damage. Steel ball bearings with moderate amounts of carbon are tough, durable, and water-resistant. They’re ideal for gears, but their high-carbon steel counterparts are particularly tough and can resist corrosion.

A ceramic ball bearing is another option. This type has steel inner and outer rings but ceramic balls. Ceramic balls can withstand higher temperatures than steel and are also electrically insulating. Ceramic ball bearings also tend to be lighter and are more resistant to wear and tear. They’re also ideal for applications in which grease is not an option, such as in space shuttles. Despite the fact that ceramic ball bearings are tough, they’re still cheaper than steel ball bearings.

They are conductive

You may have heard the term “ball bearing” if you’ve studied introductory physics. What does that mean? Essentially, ball bearings are conductive because of their ability to conduct electricity. This ability is reflected in the charge distribution on the surface of the ball. Positive charges are drawn toward the positive plate, while negative charges are drawn away from the positively charged ball bearing. You may have even seen a ball bearing in action.

However, despite their conductive nature, ball bearings can still become damaged by electrical discharge. A higher voltage can cause the balls to pit, and the raceways to become uneven. These uneven surfaces will first show up as excessive noise, and eventually cause the bearing to malfunction. Fortunately, engineers have found a way to counter this problem: conductive grease. This grease enables current to flow through the ball bearing, preventing both heat and voltage buildup.

The difference between steel and ceramic ball bearings is their density. Steel bearings are more conductive than glass or hybrid ceramics. Steel ball bearings have an even grain structure and are conductive for resonance flow. When moving fast, the air surrounding the steel ball bearing carries resonance from the inner ring to the outer. This makes them ideal for high-speed resonance transfer. In addition to being conductive, glass microbeads are harder and lighter than steel.

They are used in pulley systems

Pulley systems use ball bearings to move the sprocket, which is a wheel that rotates. These bearings are installed on the center mounting hole of the pulley wheel. They protect the entire system from heat, while allowing higher speed and smooth operation. They distribute the weight of the load evenly, minimizing friction and wobbling, and ensure a smooth rotation. Ball bearings are typically made from steel and are installed inside the pulley wheel.

The moment of inertia and bearing friction are measured to within ten percent accuracy. These two variables affect the speed of the pulley system, which can lead to crashes if the weight holders are not balanced. Therefore, ball bearings are used to minimize the chance of such crashes. When you want to know more about ball bearings in pulley systems, here are the advantages they provide.

Another benefit of ball bearings in pulley systems is that they have lower friction than their solid counterparts. In order to reduce friction, however, ball bearings must be made of good materials. Some of the common ball materials are high-quality plastics and stainless steel. Good materials and clever block design are essential to minimizing friction. If you are planning to use ball bearings in your pulley system, check out the following tips and make sure you are choosing the right one for your application.

editor by CX 2023-03-27

China RN312M Cylindrical Roller Bearing RN312 brass cage eccentric bearing size 60x113x31mm with Great quality

Kind: Roller

Composition: cylindrical

Applicable Industries: Other

Product Variety: RN312

Precision Rating: P0 P6 P5 P4 P2

Seals Sort: Open

Amount of Row: Single row

Merchandise title: roller bearing

Content: Chrome Metal

Inner diameter: 60

Outer diamater: 113

Thickness: 31

Guarantee: 1 yr

Certification: ISO9001

Deal: Unique Bundle

Packaging Information: A: tube package + outer carton + pallets B: single box + outer carton + pallets C: tube package + center box + outer carton + pallets D: According to your ask for

Port: HangZhou,HangZhou and so on

The connected models:

| Bearing No. | Boundary Dimensions (mm) | Basic Load Rating (KN) | Mass | |||||

| d | D | B | C | Co | kg | |||

| N308EM | NU308EM | NJ308EM | 40 | ninety | 23 | 76.8 | seventy seven.8 | .sixty five |

| N309EM | NU309EM | NJ309EM | 45 | a hundred | 25 | ninety three. | 98. | .95 |

| N310EM | NU310EM | NJ310EM | fifty | one hundred ten | 27 | one hundred and five. | 112. | one.20 |

| N311EM | NU311EM | NJ311EM | 55 | 120 | 29 | 128. | 138. | one.61 |

| N312EM | NU312EM | NJ312EM | 60 | one hundred thirty | 31 | 142. | a hundred and fifty five. | 1.ninety four |

| N313EM | NU313EM | NJ313EM | 65 | a hundred and forty | 33 | one hundred seventy. | 188. | 2.42 |

| N314EM | NU314EM | NJ314EM | 70 | 150 | 35 | 195. | 220. | 2.90 |

| N315EM | NU315EM | NJ315EM | seventy five | a hundred and sixty | 37 | 228. | 260. | three.fifty nine |

| N316EM | NU316EM | NJ316EM | eighty | 170 | 39 | 245. | 270. | 3.ninety |

| N317EM | NU317EM | NJ317EM | 85 | a hundred and eighty | forty one | 265. | 280. | five.20 |

| N318EM | NU318EM | NJ318EM | ninety | one hundred ninety | forty three | 290. | 320. | 6.seventeen |

| N319EM | NU319EM | NJ319EM | ninety five | two hundred | 45 | 320. | 350. | six.ninety two |

| N320EM | NU320EM | NJ320EM | a hundred | 215 | 47 | 355. | 380. | 8.24 |

| N322EM | NU322EM | NJ322EM | one hundred ten | 240 | fifty | 415. | 470. | 11.20 |

| N326EM | NU326EM | NJ326EM | a hundred thirty | 280 | fifty eight | 615. | 735. | 19.thirty |

| N328EM | NU328EM | NJ328EM | one hundred forty | 300 | sixty two | 665. | 795. | 23.70 |

| N330EM | NU330EM | NJ330EM | a hundred and fifty | 320 | sixty five | 715. | 855. | 26.80 |

About Cylindrical roller bearings:

1.Cylindrical roller bearings are separable bearings, installation and removing is extremely handy.2.Cylindrical roller bearings can withstand higher radial load, suitable for use in high pace purposes.3.Cylindrical roller bearings can be divided into solitary row, double row and multi-row cylindrical roller bearings and other diverse buildings.4.Cylindrical roller bearings can be divided into PO, P6, P5, P4, P2 in accordance to precision class.

Cylindrical roller bearing are of large load ability and can run at substantial speeds due to the fact they use rollers as their rolling factors. They can consequently be employed in apps involving hefty radial and impact loading.The rollers are cylindrical in form and crowned at the end in get to decrease the stress concentrations. They are also suitable for applications that need higher velocity due to the fact the rollers are guided by CZPT which are either on the outer or internal ring.There are diverse varieties specified NU, NJ, NUP, N, NF for single-row bearings, and NNU, NN for double-row bearings based on the design and style or absence of aspect ribs.

Attributes

NSK NU314EM NUP205EM One row Cylindrical Roller Bearing with brass, ring guided cage. These EM collection Cylindrical roller bearings have larger load carrying capability, reduced noise and exceptional cage strength than the normal type.

Parameters

| Solution Identify | Cylindrical Roller Bearing |

| Content | Chrome Steel |

| Manufacturer name | LLH |

| Sequence | RN312M |

| Vibration | V1,V2,V3,V4 |

| Precision Score | P0 P6 P5 P4 P2 |

| Quality standard | ISO9001, ABEC-1(Z1V1) |

| Tolerance Grades | ABEC-1 (P0), ABEC-3 (P6),ABEC-5(P5) |

Packaging and shipping and delivery

A: tube deal + outer carton + pallets B: single box + outer carton + pallets C: tube package + center box + outer carton + pallets D: In accordance to your ask for