Product Description

Angular contact ball bearing BS4575TN1 45*75*15mm

Industrial robot bearings

Electric Motor bearings

Industrial kiln bearings

Product Description

| Structure | Angular contact ball bearing |

| Item No. | BS4575TN1 |

| Internal Diameter | 45mm |

| External Diameter | 75mm |

| Width | 15mm |

| 718 Series Angular Contact Bearings |

| 719 Series Angular Contact Bearings |

| H719 Series Angular Contact Bearings |

| 70 Series Angular Contact Bearings |

| H70 Series Angular Contact Bearings |

| B70 Series Angular Contact Bearings |

| 72 Series Angular Contact Bearings |

Company

HangZhou Auto Bearing Co., Ltd. is located in the industrial park of HangZhou,which is 1 of the 4 great ancient capitals of China.Our company is the member of China Bearing Industry Association,cooperating with State Quality Supervision and Testing Center for bearing.Our company is a professional bearing manufacturer which integrated with research ,development and marketing services.

Our major products include deep groove ball bearing, spherical roller bearing, slewing ring, crossed roller bearing and other all kinds of high precision bearings.Our products are widely applied to motor industry,mining metallurgy,wind power generation,petroleum drilling,automobile and motorcycle etc..

Our company not only possesses advanced bearing manufacturing equipments and international first-class measuring instruments, but also has strong strength of manufacturing, inspecting and testing the high precision and reliability bearings.Each process is in strict accordance with the ISO9001 quality management system,which effectively guarantees the precise of products and stability of the performance. AUTO bearings are mainly exported to the United states,South Korea,Europe,etc., which have reached the high level of foreign similar products.

The soul of our business culture is [Detail makes competitive, innovation makes first-class”.We believe the production and management philosophy of [quality wins ,casting competitive products”.The company adheres to the zero-defect quality management for meeting customer requirements.

Packing

A. plastic box & outer carton & pallets

B. plastic bag & box & carton & pallet

C. tube package & middle box & carton & pallet

D. Depends on your needs

Delivery

A. Most orders will be shipped within 3-5 days of payment being received.

B. Samples will be shipped by cov2urier as FedEx,UPS,DHL,etc.

Thank you very much for taking time to view our company’s website. If you are interested in this product, please feel free to contact us. We are always here.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 25° |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

| Customization: |

Available

| Customized Request |

|---|

What are the potential challenges or limitations associated with using rolling contact bearings in various industries?

Rolling contact bearings offer numerous benefits and are widely used in various industries. However, there are certain challenges and limitations associated with their use. It is important to understand these potential issues to ensure proper application and mitigate any adverse effects. Here’s a detailed explanation of the challenges and limitations associated with using rolling contact bearings:

- Load Capacity:

While rolling contact bearings are designed to handle substantial loads, there are limitations to their load capacity. Exceeding the specified load limits can lead to premature wear, increased friction, and potentially catastrophic failure. It is crucial to consider the expected loads in the application and select bearings with appropriate load ratings and configurations. In some high-load applications, alternative bearing types, such as spherical roller bearings or tapered roller bearings, may be more suitable to handle the specific load requirements.

- Speed Limitations:

Rolling contact bearings have speed limitations that need to be considered in high-speed applications. At high rotational speeds, centrifugal forces can affect the performance and reliability of rolling contact bearings. The limitation is primarily due to factors such as the bearing’s internal clearance, cage design, lubrication, and the potential for increased heat generation. To overcome speed limitations, specialized high-speed bearings with improved designs and materials, such as ceramic balls or hybrid bearings, may be used in certain applications.

- Maintenance and Lubrication:

Proper maintenance and lubrication are essential for the reliable operation of rolling contact bearings. Inadequate lubrication or improper maintenance practices can result in increased friction, heat buildup, and premature wear. It is important to follow the manufacturer’s recommendations for lubrication intervals, lubricant selection, and application methods. In some applications, such as high-temperature environments or extreme operating conditions, special considerations may be required to ensure effective lubrication and prevent bearing failure.

- Environmental Factors:

Rolling contact bearings can be sensitive to certain environmental factors. Exposure to contaminants, such as dirt, dust, moisture, or aggressive chemicals, can lead to accelerated wear and corrosion. In industries where the operating environment is harsh or contaminated, additional protective measures, such as sealing arrangements or the use of specialized coatings, may be necessary to enhance the bearing’s resistance to environmental factors. It is important to evaluate the specific environmental conditions and select bearings that are suitable for the intended application.

- Installation and Alignment:

Improper installation or misalignment of rolling contact bearings can result in reduced performance and premature failure. Achieving accurate alignment and proper fitment during installation is crucial. Misalignment can lead to increased friction, uneven load distribution, and potential damage to the bearing surfaces. It is necessary to follow the manufacturer’s installation guidelines, use appropriate tools, and employ precision alignment techniques to ensure optimal performance and longevity of the bearings.

- Size and Space Constraints:

In some applications, size and space constraints may limit the use of rolling contact bearings. The available space for bearing installation may be limited, requiring the use of compact or specialized bearing designs. Additionally, certain applications may demand high load-carrying capacity within a restricted envelope, necessitating careful bearing selection and possibly the use of alternative bearing types. It is important to consider the space limitations and select bearings that can accommodate the specified requirements while fitting within the available space.

While rolling contact bearings offer numerous advantages, it is essential to be aware of the potential challenges and limitations associated with their use. By understanding these factors and taking appropriate measures, such as careful selection, proper maintenance, and adherence to installation guidelines, the performance and reliability of rolling contact bearings can be optimized in various industries and applications.

Can you provide guidance on the selection and sizing of rolling contact bearings for specific applications?

Yes, I can provide guidance on the selection and sizing of rolling contact bearings for specific applications. Choosing the right rolling contact bearings involves considering various factors such as load requirements, operating conditions, speed, and environmental factors. Here’s a detailed explanation of the steps involved in selecting and sizing rolling contact bearings:

- Identify Application Requirements:

Start by identifying the specific requirements of your application. Consider factors such as the type and magnitude of the loads the bearing will be subjected to, the operating speed, and any special environmental conditions like temperature, moisture, or exposure to corrosive substances. Understanding these requirements is crucial as it forms the basis for selecting the appropriate rolling contact bearing.

- Analyze Load Conditions:

Next, analyze the load conditions acting on the bearing. Determine if the load is radial, axial, or a combination of both. Consider factors such as the magnitude, direction, and frequency of the load. This analysis helps in determining the appropriate bearing type, such as deep groove ball bearings, angular contact ball bearings, cylindrical roller bearings, or tapered roller bearings, that can handle the specific load conditions effectively.

- Calculate Equivalent Load:

Calculate the equivalent load acting on the bearing. In cases where the load acting on the bearing is a combination of radial and axial loads, it is necessary to calculate the equivalent load. The equivalent load accounts for the differing effects of radial and axial loads on the bearing and helps in determining the required bearing size and capacity.

- Consider Speed and Operating Conditions:

Take into account the speed at which the bearing will operate and the specific operating conditions. Higher speeds may require bearings with special design features or materials to handle the increased centrifugal forces and temperature rise. Consider factors such as lubrication requirements, temperature limits, and any special considerations for factors like shock loads, vibrations, or misalignment. These factors influence the selection of appropriate bearing types and configurations.

- Consult Bearing Manufacturer’s Catalogs:

Refer to the catalogs or technical specifications provided by bearing manufacturers. These catalogs contain detailed information about various bearing types, sizes, load ratings, and performance characteristics. Use the information provided to narrow down the options based on your application requirements and load calculations.

- Verify Bearing Life:

Check the calculated bearing life to ensure it meets the required operational lifespan of your application. Bearing manufacturers provide life calculation formulas based on industry standards such as ISO or ABMA. These formulas take into account factors like load, speed, and reliability requirements to estimate the expected bearing life. Verify that the selected bearing will provide the desired operational lifespan under the given operating conditions.

- Consider Mounting and Dismounting:

Lastly, consider the ease of mounting and dismounting the bearing in your specific application. Evaluate factors such as the bearing’s fit tolerance, the required clearance or preload, and any special mounting or dismounting procedures. Ensure that the selected bearing can be easily installed and maintained in your application.

It is important to note that the selection and sizing of rolling contact bearings can be complex, and it is advisable to seek the assistance of bearing manufacturers, engineers, or experts in the field to ensure the optimal selection for your specific application.

How do rolling contact bearings contribute to reduced friction and improved efficiency in machinery?

Rolling contact bearings play a crucial role in reducing friction and improving the efficiency of machinery. They achieve this through several design features and operating characteristics. Here’s a detailed explanation of how rolling contact bearings contribute to reduced friction and improved efficiency:

- Rolling Motion:

Unlike sliding contact bearings, which rely on sliding friction between surfaces, rolling contact bearings utilize rolling motion between the rolling elements (balls or rollers) and the raceways. This rolling motion significantly reduces friction compared to sliding friction, resulting in lower energy losses and improved efficiency. The rolling contact between the elements and the raceways minimizes surface contact and allows smooth rotation with reduced frictional resistance.

- Lubrication:

Rolling contact bearings are typically lubricated with oils or greases to further reduce friction and wear. Lubricants form a thin film between the rolling elements and the raceways, providing a protective layer that separates the surfaces and minimizes direct metal-to-metal contact. This lubricating film reduces friction and dissipates heat generated during operation, contributing to smoother rotation and improved efficiency.

- Reduced Sliding Friction:

As mentioned earlier, rolling contact bearings rely on rolling motion rather than sliding friction. This design characteristic reduces the occurrence of sliding friction between the bearing components, resulting in lower frictional forces and decreased energy losses. The reduced sliding friction contributes to improved efficiency and can translate into energy savings in various machinery applications.

- Load Distribution:

Rolling contact bearings distribute loads more evenly compared to sliding contact bearings. The rolling elements in a bearing share the load and distribute it over a larger contact area, reducing localized stress and minimizing friction. This load distribution characteristic helps prevent excessive wear and prolongs the service life of the bearing. By maintaining efficient load distribution, rolling contact bearings contribute to improved efficiency and reliability in machinery.

- High-Speed Capability:

Rolling contact bearings are well-suited for high-speed applications due to their low friction characteristics. The rolling motion and reduced sliding friction allow these bearings to rotate at higher speeds with minimal heat generation. This high-speed capability is essential for various machinery, such as electric motors, machine tools, and automotive components, where efficient power transmission and rotational precision are critical for optimal performance and efficiency.

In summary, rolling contact bearings contribute to reduced friction and improved efficiency in machinery through their rolling motion, effective lubrication, reduced sliding friction, even load distribution, and high-speed capability. These design features and operating characteristics minimize energy losses, reduce wear, and enhance the overall performance and reliability of machinery in a wide range of industries.

editor by CX 2024-05-15

China wholesaler Machine Tool Bearing Import CZPT Brand 7019c 7011CTA Angular Contact Ball Bearing bearing example

Product Description

Product Description

| Item | Value |

| Type | ball bearing |

| Structure | cage |

| Applicable Industries | Energy & Mining |

| Brand Name | TIMKEN/KOYO/NTN/NSK |

| Precision Rating | P0 P4 P5 P6 |

| Seals Type | OPEN |

| Number of Row | Double Rows |

| Place of Origin | China |

Angular Contact Ball Bearings can bear both radial load and axial load. Can work at higher speeds. The larger the contact angle, the higher the axial load capacity. High-precision and high-speed bearings usually have a contact angle of 15 degrees. Under the action of axial force, the contact angle will increase.

Angular contact bearings are ideal for use in gearboxes, pumps, electric motors, and clutches or other high-speed applications.They are commonly used in the Materials Handling, Machine Tool, Steel Mill, and Wind Energy industries.

Although angular contact bearings can accept thrust loads in only 1 direction, they can be manufactured at different contact angles (usually between 0 and 45 degrees) to transfer the load acting upon the bearing.

| Model | d mm | D mm | H mm | W kg |

| 7000AC | 10 | 26 | 8 | 0.02 |

| 7001AC | 12 | 28 | 8 | 0.02 |

| 7002AC | 15 | 32 | 9 | 0.03 |

| 7003AC | 17 | 35 | 10 | 0.03 |

| 7004AC | 20 | 42 | 12 | 0.07 |

| 7005AC | 25 | 47 | 12 | 0.08 |

| 7006AC | 30 | 55 | 13 | 0.12 |

| 7007AC | 35 | 62 | 14 | 0.14 |

| 7008AC | 40 | 68 | 15 | 0.21 |

| 7009AC | 45 | 75 | 16 | 0.24 |

| 7571AC | 50 | 60 | 16 | 0.26 |

Product Display

Company Profile

ZheJiang Ponchi New Energy Technology Co., Ltd. is establised in2571, The company is mainly committed to the promotion and sales of world-famous bearing brands.Over the years it has established good cooperative relations with many companies,with a wide range of products lt is used in machinery, mining,steel.electric paper, automobile and other fields.

With reasonable commodity price,fast logistics delivery,high-quality service, and strong technical force, the company has won the support and trustof customers and truly achieved a CZPT situation between the company and customers.

“Customer’s requirement is our pursuit” the company will always adhere to the new concept of people-oriented, customer service, keeping pace with the times, development and innovation”.

Certifications

Cooperation brand

Packaging & Shipping

FAQ

1. Who are we?

We are based in ZheJiang , China, start from 2019,sell to South America(30.00%),Mid East(25.00%),North

America(20.00%),Africa(15.00%),Southeast Asia(10.00%). There are total about 1000+ people in our office.

2. How can we guarantee quality?

Always a pre-production sample before mass production;

Always final Inspection before shipment;

3.What can you buy from us?

bearing,ball bearing,Roller bearing,Deep groove ball bearing,Tapered roller bearing

4. Why should you buy from us not from other suppliers?

We have more than 20 years of production experience, we have enough inventory to provide you with a full range of bearings, we

have efficient delivery speed, and can provide you with the packaging you need

5. What services can we provide?

Accepted Delivery Terms: FOB,CFR,CIF,EXW,FAS,CIP,FCA,CPT,DEQ,DDP,DDU,Express Delivery,DAF,DES;

Accepted Payment Currency:USD,EUR,JPY,CAD,AUD,HKD,GBP,CNY,CHF;

Accepted Payment Type: T/T,L/C,D/P D/A,MoneyGram,Credit Card,PayPal,Western Union,Cash,Escrow;

Language Spoken:English,Chinese,Spanish,Japanese,Portuguese,German,Arabic,French,Russian,Korean,Hindi,Italian /* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 15° |

|---|---|

| Aligning: | Aligning Bearing |

| Separated: | Unseparated |

| Samples: |

US$ 8.01/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

|

Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

Can you explain the installation and alignment considerations for rolling contact bearings?

Proper installation and alignment are crucial for the optimal performance and longevity of rolling contact bearings. Incorrect installation or misalignment can lead to premature wear, increased friction, reduced load-carrying capacity, and potential bearing failure. Here’s a detailed explanation of the installation and alignment considerations for rolling contact bearings:

- Clean and Proper Workspace:

Before installing rolling contact bearings, it is essential to ensure a clean and suitable workspace. The work area should be free from dirt, dust, debris, and contaminants that could enter the bearing during installation. Contamination can cause damage to the bearing surfaces and compromise its performance. Additionally, the workspace should have appropriate tools and equipment to facilitate the installation process, including bearing pullers, mounting tools, and measurement instruments.

- Handling and Storage:

Rolling contact bearings should be handled with care to prevent damage to the bearing surfaces. They should be stored in a clean and dry environment, protected from moisture, dust, and extreme temperatures. During handling, it is important to avoid dropping or impacting the bearings, as this can cause surface damage or internal defects. Proper handling and storage practices help maintain the integrity of the bearings and ensure their performance during installation.

- Shaft and Housing Preparation:

Prior to installing the rolling contact bearings, the shaft and housing surfaces must be prepared appropriately. The shaft and housing should be clean, free from burrs, and have the correct dimensions and tolerances specified by the bearing manufacturer. Any roughness or irregularities on the shaft or housing can affect the fit and alignment of the bearing, leading to performance issues. It may be necessary to use appropriate tools, such as emery cloth or a deburring tool, to smooth the surfaces and ensure proper fitment.

- Bearing Mounting:

When mounting rolling contact bearings, it is essential to follow the manufacturer’s recommended procedures and guidelines. This includes using the appropriate mounting tools and techniques to apply the necessary axial or radial force evenly during installation. Overloading or uneven force application can lead to bearing damage or misalignment. Proper mounting techniques may involve using a press, heat, or specialized mounting tools to ensure the bearing is seated securely and accurately on the shaft or in the housing.

- Alignment:

Accurate alignment of rolling contact bearings is critical for their optimal performance. Misalignment can cause increased friction, premature wear, and reduced load-carrying capacity. It is important to align the bearing with respect to the shaft and housing to ensure proper concentricity and parallelism. Alignment methods may include visual alignment, feeler gauges, dial indicators, laser alignment systems, or other precision alignment tools. The specific alignment requirements may vary depending on the bearing type, application, and manufacturer recommendations.

- Lubrication:

Proper lubrication is essential during the installation of rolling contact bearings. The bearing manufacturer’s recommendations should be followed regarding the type, quantity, and method of lubrication. Lubrication helps reduce friction, dissipate heat, and protect against wear and corrosion. It is important to ensure that the bearing is adequately lubricated during installation to facilitate smooth operation and prevent damage.

- Verification and Testing:

After installation, it is recommended to verify the proper fitment, alignment, and operation of the rolling contact bearings. This may involve checking the axial and radial clearances, measuring runout, and performing functional tests to ensure smooth rotation and proper load distribution. Verification and testing help confirm the successful installation and identify any potential issues that may require adjustment or corrective action.

In summary, proper installation and alignment considerations are essential for the optimal performance and longevity of rolling contact bearings. Following recommended procedures, handling the bearings carefully, preparing the shaft and housing surfaces, ensuring accurate alignment, and providing appropriate lubrication contribute to the successful installation and reliable operation of rolling contact bearings in various applications.

What is the role of cage design and materials in rolling contact bearing performance and durability?

The cage design and materials used in rolling contact bearings play a crucial role in their performance and durability. Here’s a detailed explanation of the role of cage design and materials in rolling contact bearing performance and durability:

- Function of the Cage:

The cage, also known as the bearing retainer or separator, holds and separates the rolling elements in a rolling contact bearing. Its primary function is to maintain the proper spacing and alignment of the rolling elements, allowing them to roll smoothly and distribute the load evenly. The cage prevents the rolling elements from contacting each other, reducing friction, wear, and the risk of damage. By guiding the rolling elements, the cage also helps to minimize the centrifugal forces and maintain stability at high speeds. The design and materials of the cage directly influence these functions and, consequently, the overall performance and durability of the bearing.

- Cage Design Considerations:

The design of the cage is carefully considered to ensure optimal bearing performance and durability. Some key design considerations include:

- Material Compatibility: The cage material must be compatible with the operating conditions and lubricants used in the bearing. It should have sufficient strength, hardness, and resistance to wear and fatigue. Different applications may require cages made from materials such as steel, brass, synthetic polymers, or composite materials.

- Friction and Heat Generation: The cage design should minimize friction between the rolling elements and the cage itself. Reduced friction helps improve energy efficiency, reduce heat generation, and extend the bearing’s service life.

- Load Distribution: The cage design should facilitate even load distribution among the rolling elements. This ensures that the forces acting on the bearing are evenly distributed, reducing stress concentrations and the risk of premature failure.

- High-Speed Capability: The cage design should be optimized to handle high-speed applications. It should be lightweight, promote efficient lubricant flow, and minimize windage losses caused by air turbulence at high rotational speeds.

- Alignment and Stability: The cage design should promote proper alignment and stability of the rolling elements, especially during rapid accelerations, decelerations, or changes in direction. This helps maintain smooth operation and prevents the rolling elements from skewing or becoming misaligned.

- Cage Material Selection:

The choice of cage material depends on factors such as the operating conditions, load requirements, lubrication, and cost considerations. Commonly used cage materials include:

- Steel: Steel cages offer excellent strength, durability, and resistance to high temperatures. They are commonly used in applications with heavy loads, high speeds, and high operating temperatures.

- Brass: Brass cages provide good strength, corrosion resistance, and low friction. They are suitable for applications where low noise and vibration levels are important, such as in precision instruments and industrial machinery.

- Synthetic Polymers: Synthetic polymer cages, such as polyamide (nylon) or polyetheretherketone (PEEK), offer advantages such as low friction, lightweight, corrosion resistance, and the ability to dampen vibrations. They are commonly used in applications where reducing friction, noise, and weight are critical, such as in automotive and aerospace industries.

- Composite Materials: Composite cages combine different materials to achieve specific properties such as high strength, low friction, or resistance to harsh environments. These cages are used in specialized applications where unique material properties are required.

The selection of the cage design and materials is a critical aspect of rolling contact bearing design. Careful consideration of the operating conditions, load requirements, speed, and other factors helps ensure optimal performance, reliability, and durability of the bearing.

What are the common types of rolling contact bearings, such as ball bearings or roller bearings?

Rolling contact bearings are available in various types, each designed to accommodate specific load capacities, speeds, and application requirements. The most common types of rolling contact bearings include ball bearings and roller bearings. Here’s a detailed explanation of these common types:

- Ball Bearings:

Ball bearings are the most widely used type of rolling contact bearings. They consist of one or more rows of balls placed between two rings—an inner ring and an outer ring. The balls roll along the raceways formed on the rings, enabling smooth and low-friction rotation. Ball bearings are known for their high rotational speeds, low starting torque, and relatively low load capacity compared to roller bearings.

There are several variations within the category of ball bearings, including:

- Deep Groove Ball Bearings: These ball bearings have deep raceway grooves, allowing them to accommodate both radial and axial loads. They are commonly used in applications such as electric motors, appliances, and automotive components.

- Angular Contact Ball Bearings: Angular contact ball bearings can handle both radial and axial loads. They have an angled contact surface between the balls and the raceways, enabling them to support higher axial loads and facilitate combined radial and axial movements. These bearings are often used in machine tools, pumps, and gearboxes.

- Thrust Ball Bearings: Thrust ball bearings are designed to support axial loads in a single direction. They consist of two rings with a set of balls sandwiched between them. Thrust ball bearings are commonly used in applications such as automotive transmissions and steering systems.

- Roller Bearings:

Roller bearings, as the name implies, utilize cylindrical or tapered rollers instead of balls to facilitate motion. Roller bearings are capable of handling higher loads and are often used in heavy-duty applications. The common types of roller bearings include:

- Cylindrical Roller Bearings: Cylindrical roller bearings feature cylindrical rollers that provide a large contact area with the raceways. They can accommodate high radial loads and moderate axial loads. Cylindrical roller bearings are commonly used in applications such as machine tool spindles, electric motors, and gearboxes.

- Tapered Roller Bearings: Tapered roller bearings consist of tapered rollers and inner and outer rings with tapered raceways. They can support both radial and axial loads in a single direction. Tapered roller bearings are commonly used in automotive wheel bearings, heavy machinery, and construction equipment.

- Spherical Roller Bearings: Spherical roller bearings have barrel-shaped rollers and two raceways on the inner and outer rings that are inclined relative to the bearing axis. This design allows them to accommodate misalignment and axial displacement. Spherical roller bearings are commonly used in applications with heavy loads, such as mining equipment, paper mills, and crushers.

- Needle Roller Bearings: Needle roller bearings use long, thin rollers that have a high length-to-diameter ratio. They are suitable for applications with limited radial space and high load capacity. Needle roller bearings are commonly used in automotive transmissions, industrial gearboxes, and motorcycle engines.

These are some of the common types of rolling contact bearings, including ball bearings and roller bearings. Each type has its own advantages and is suitable for specific applications based on factors such as load requirements, speed, and space limitations.

editor by CX 2024-05-13

China OEM 71813c/AC/B High-Speed Angular Contact Ball Bearings P6/P5/P4/P2 Used in Machine Tool Spindles bearing example

Product Description

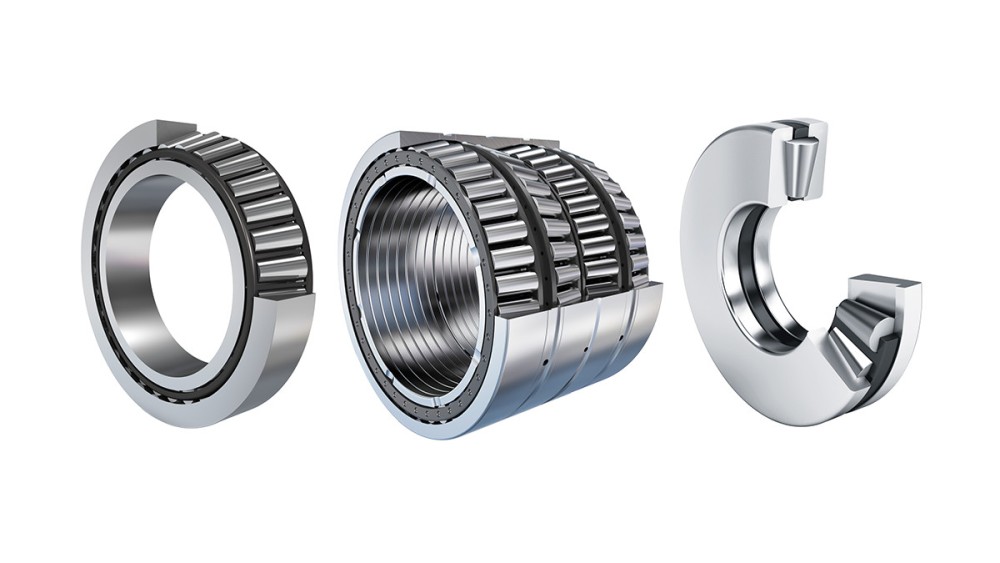

This type of bearing is used to bear heavier radial-axial combined loads with limit rotational speeds higher. The bearings are mainly applied to the construction parts that limit axial displacement of the axis or housing in double directions.

The bearing is used with 4 row cylindrical roller bearings limiting the axial motion of roll in rolling mill the axial load capactiy is heavier than four-point contact ball ebearings incomparison with paiy mounted in back-to-back, face-to-face arvangements single row angular contact ball bearings units, the axial clearance of the bearing doesn’t need adjustment, these bearings can be mounted with ease and there can be 2 types: 2 half-outer-rings and 2 half-inner-rings according to the installation need of customers.

| Bearing Designations | Boundary Dimensions(mm) | Load rating (KN) |

Limiting Speed (r/min) | Mass kg |

||||||||||||

| 71813 C | d | D | B | Rsmin | Rlsmin | a | Dynamic Cr | Static Cor | Grease | Oil | ||||||

| 65 | 85 | 10 | 0.60 | 0.15 | 15 | 13.4 | 18.8 | 14000 | 22000 | 0.125 | ||||||

| 718 Series Angular Contact Bearings |

| 719 Series Angular Contact Bearings |

| H719 Series Angular Contact Bearings |

| 70 Series Angular Contact Bearings |

| H70 Series Angular Contact Bearings |

| B70 Series Angular Contact Bearings |

| 72 Series Angular Contact Bearings |

Company

HangZhou Auto Bearing Co., Ltd. is located in the industrial park of HangZhou,which is 1 of the 4 great ancient capitals of China.Our company is the member of China Bearing Industry Association,cooperating with State Quality Supervision and Testing Center for bearing.Our company is a professional bearing manufacturer which integrated with research ,development and marketing services.

Our major products include deep groove ball bearing, spherical roller bearing, slewing ring, crossed roller bearing and other all kinds of high precision bearings.Our products are widely applied to motor industry,mining metallurgy,wind power generation,petroleum drilling,automobile and motorcycle etc..

Our company not only possesses advanced bearing manufacturing equipments and international first-class measuring instruments, but also has strong strength of manufacturing, inspecting and testing the high precision and reliability bearings.Each process is in strict accordance with the ISO9001 quality management system,which effectively guarantees the precise of products and stability of the performance. AUTO bearings are mainly exported to the United states,South Korea,Europe,etc., which have reached the high level of foreign similar products.

The soul of our business culture is [Detail makes competitive, innovation makes first-class”.We believe the production and management philosophy of [quality wins ,casting competitive products”.The company adheres to the zero-defect quality management for meeting customer requirements.

Packing

A. plastic box & outer carton & pallets

B. plastic bag & box & carton & pallet

C. tube package & middle box & carton & pallet

D. Depends on your needs

Delivery

A. Most orders will be shipped within 3-5 days of payment being received.

B. Samples will be shipped by cov2urier as FedEx,UPS,DHL,etc.

Thank you very much for taking time to view our company’s website. If you are interested in this product, please feel free to contact us. We are always here.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 15°/25°/40° |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Radial Bearing |

| Material: | Bearing Steel |

| Samples: |

US$ 0.1/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

How do rolling contact bearings perform in high-speed or high-load applications?

Rolling contact bearings are designed to perform effectively in high-speed and high-load applications. Their specific design features and characteristics allow them to withstand the demands and challenges associated with these conditions. Here’s a detailed explanation of how rolling contact bearings perform in high-speed or high-load applications:

- High-Speed Performance:

Rolling contact bearings are well-suited for high-speed applications due to their low friction characteristics. The rolling motion between the rolling elements and the raceways minimizes friction and heat generation, enabling smooth rotation at high speeds. The design of rolling contact bearings, including the selection of suitable materials and precision manufacturing, ensures the balance between load-carrying capacity and reduced friction at high speeds. As a result, these bearings can operate efficiently and reliably in applications such as electric motors, machine tools, turbochargers, and aerospace systems that require rapid and precise rotational motion.

- High-Load Capacity:

Rolling contact bearings are engineered to handle high loads and distribute them effectively. The rolling elements in the bearings, such as balls or rollers, distribute the applied loads over a larger contact area, reducing stress concentrations and preventing premature failure. The materials used in rolling contact bearings, such as high-grade steels and specialized alloys, provide the necessary strength and durability to withstand heavy loads. Additionally, the design of the bearing, including the number and size of the rolling elements, the geometry of the raceways, and the cage construction, is optimized to maximize load-carrying capacity. This enables rolling contact bearings to perform reliably in high-load applications, including heavy machinery, automotive drivetrains, construction equipment, and industrial processes.

- Lubrication for High-Speed and High-Load Conditions:

Lubrication is crucial for the performance of rolling contact bearings in high-speed or high-load applications. The lubricant helps reduce friction, dissipate heat, and prevent wear and damage to the bearing surfaces. For high-speed applications, specialized lubricants with low viscosity and high thermal stability are often used to ensure efficient lubrication and prevent excessive heat buildup. In high-load applications, lubrication plays a vital role in load distribution and reducing the risk of premature failure due to excessive stress. Proper lubrication selection and maintenance are essential to ensure optimal performance and longevity of rolling contact bearings under high-speed or high-load conditions.

- Preload and Stiffness:

In certain high-speed or high-load applications, rolling contact bearings may be preloaded to enhance their stiffness and improve their performance. Preload is a controlled axial force applied to the bearing that eliminates internal clearances and minimizes deflection under load. By applying preload, the rolling contact bearings can maintain their dimensional stability, minimize vibration, and enhance their ability to handle high-speed or high-load conditions. Preload is commonly utilized in precision machine tools, spindle bearings, and other applications where rotational accuracy and rigidity are critical.

In summary, rolling contact bearings perform exceptionally well in high-speed or high-load applications. They are designed to minimize friction, handle heavy loads, and maintain operational integrity under demanding conditions. Through their low friction characteristics, high-load capacity, appropriate lubrication, and potential use of preload, rolling contact bearings ensure reliable and efficient operation in various industries and applications requiring high-speed or high-load capabilities.

What are the eco-friendly or sustainable aspects of rolling contact bearing materials?

Rolling contact bearing materials can contribute to eco-friendliness and sustainability in several ways. Here’s a detailed explanation of the eco-friendly and sustainable aspects of rolling contact bearing materials:

- Recyclability:

Many rolling contact bearing materials, such as steel and certain types of alloys, are highly recyclable. At the end of their service life, bearings can be dismantled, and the materials can be recycled or reused. Recycling bearings helps reduce the demand for raw materials, conserves energy, and minimizes waste generation. By promoting a circular economy, the recyclability of bearing materials contributes to resource conservation and waste reduction.

- Energy Efficiency:

Rolling contact bearings play a crucial role in improving energy efficiency in various applications. By reducing friction and minimizing power losses, bearings help optimize the performance of machinery and equipment. When machines operate more efficiently, they consume less energy, leading to reduced greenhouse gas emissions and lower carbon footprints. The use of high-quality bearing materials, coatings, and lubricants further enhances energy efficiency by minimizing frictional losses.

- Long Service Life:

Rolling contact bearings are designed to have long service lives under normal operating conditions. Their ability to withstand heavy loads, resist wear, and operate reliably contributes to extended equipment lifetimes. By reducing the frequency of bearing replacements, industries can minimize material consumption, waste generation, and environmental impact associated with manufacturing and disposal processes. The longer service life of rolling contact bearings promotes sustainability by reducing resource consumption and improving equipment lifecycle management.

- Reduced Maintenance:

The use of high-quality rolling contact bearing materials can contribute to reduced maintenance requirements. Bearings that are resistant to wear, corrosion, and fatigue offer longer maintenance intervals, reducing the need for frequent inspections, replacements, and repairs. This not only saves time and labor but also reduces the consumption of maintenance-related resources such as lubricants and spare parts. The reduced maintenance needs of rolling contact bearings contribute to sustainable operations by optimizing resource utilization and minimizing maintenance-related waste.

- Environmental Compliance:

Rolling contact bearing materials are subject to various environmental regulations and standards. Manufacturers strive to comply with these regulations by ensuring that their materials are free from hazardous substances or restricted substances. Compliance with regulations such as the Restriction of Hazardous Substances (RoHS) directive helps prevent the use of environmentally harmful materials, reducing the potential environmental impact during the manufacturing, use, and disposal stages of rolling contact bearings.

Overall, rolling contact bearing materials offer several eco-friendly and sustainable aspects, including recyclability, energy efficiency, long service life, reduced maintenance requirements, and compliance with environmental regulations. These aspects contribute to resource conservation, waste reduction, energy savings, and minimized environmental impact throughout the lifecycle of rolling contact bearings.

How do rolling contact bearings contribute to reduced friction and improved efficiency in machinery?

Rolling contact bearings play a crucial role in reducing friction and improving the efficiency of machinery. They achieve this through several design features and operating characteristics. Here’s a detailed explanation of how rolling contact bearings contribute to reduced friction and improved efficiency:

- Rolling Motion:

Unlike sliding contact bearings, which rely on sliding friction between surfaces, rolling contact bearings utilize rolling motion between the rolling elements (balls or rollers) and the raceways. This rolling motion significantly reduces friction compared to sliding friction, resulting in lower energy losses and improved efficiency. The rolling contact between the elements and the raceways minimizes surface contact and allows smooth rotation with reduced frictional resistance.

- Lubrication:

Rolling contact bearings are typically lubricated with oils or greases to further reduce friction and wear. Lubricants form a thin film between the rolling elements and the raceways, providing a protective layer that separates the surfaces and minimizes direct metal-to-metal contact. This lubricating film reduces friction and dissipates heat generated during operation, contributing to smoother rotation and improved efficiency.

- Reduced Sliding Friction:

As mentioned earlier, rolling contact bearings rely on rolling motion rather than sliding friction. This design characteristic reduces the occurrence of sliding friction between the bearing components, resulting in lower frictional forces and decreased energy losses. The reduced sliding friction contributes to improved efficiency and can translate into energy savings in various machinery applications.

- Load Distribution:

Rolling contact bearings distribute loads more evenly compared to sliding contact bearings. The rolling elements in a bearing share the load and distribute it over a larger contact area, reducing localized stress and minimizing friction. This load distribution characteristic helps prevent excessive wear and prolongs the service life of the bearing. By maintaining efficient load distribution, rolling contact bearings contribute to improved efficiency and reliability in machinery.

- High-Speed Capability:

Rolling contact bearings are well-suited for high-speed applications due to their low friction characteristics. The rolling motion and reduced sliding friction allow these bearings to rotate at higher speeds with minimal heat generation. This high-speed capability is essential for various machinery, such as electric motors, machine tools, and automotive components, where efficient power transmission and rotational precision are critical for optimal performance and efficiency.

In summary, rolling contact bearings contribute to reduced friction and improved efficiency in machinery through their rolling motion, effective lubrication, reduced sliding friction, even load distribution, and high-speed capability. These design features and operating characteristics minimize energy losses, reduce wear, and enhance the overall performance and reliability of machinery in a wide range of industries.

editor by CX 2024-05-09

China supplier Best Price Angular Contact Ball Bearing 7308AC 7309AC 7310AC 7311AC for Machine Tool Spindle, High Frequency Motor bearing driver kit

Product Description

Product Description

The characteristic of angular contact bearing is that it can bear both radial load and single axial load. The larger the contact Angle, the larger the axial load, the smaller the contact Angle, the smaller the axial load. Conversely, the smaller the contact Angle, the greater the ability to bear radial loads, and the more suitable for high-speed applications. According to different working conditions, it can be combined in a variety of ways to obtain different radial and axial load capacity, and meet the requirements of high speed and diameter, and high axial stiffness.

Angular contact ball bearing accuracy class includes dimensional tolerance and rotation accuracy. From low to high accuracy is expressed as P0(ordinary), P6(P6X), P5, P4, P2, in addition, P3, P7, P9 are also used in European and American brands to indicate accuracy levels, P3 is equivalent to level P6 of ISO and JS standards, P7 is equivalent to level P4, and P9 is equivalent to level P2.

Product Parameters

Product Specification

Single Row Angular Contact Ball Bearing

| Bearing type | Boundary Dimensions(mm) | Load Rating (kn) |

Speed Rating(ipm) | Weight | |||||

| New Model | Old Model | d | D | B | Dymamic Cr | Static Cor | Grease lubrication |

Oil lubrication |

Weight (kg) |

| 7000AC | 46100 | 10 | 26 | 8 | 5 | 2.35 | 34000 | 42000 | 0.571 |

| 7001AC | 46101 | 12 | 28 | 8 | 5.4 | 2.75 | 29000 | 37000 | 0.571 |

| 7002AC | 46102 | 15 | 32 | 9 | 6.1 | 3.45 | 26000 | 32000 | 0.035 |

| 7003AC | 46103 | 17 | 35 | 10 | 6.75 | 4.15 | 23000 | 28000 | 0.045 |

| 7004AC | 46104 | 20 | 42 | 12 | 10.3 | 6.1 | 19000 | 24000 | 0.079 |

| 7005AC | 46105 | 25 | 47 | 12 | 11.3 | 7.4 | 17000 | 21000 | 0.091 |

| 7006AC | 46106 | 30 | 55 | 13 | 14.5 | 10.1 | 14000 | 18000 | 0.133 |

| 7007AC | 46107 | 35 | 62 | 14 | 17.5 | 12.6 | 12000 | 15000 | 0.17 |

| 7008AC | 46108 | 40 | 68 | 15 | 18.7 | 14.6 | 11000 | 14000 | 0.21 |

| 7009AC | 46109 | 45 | 75 | 16 | 22.2 | 17.7 | 10000 | 12000 | 0.26 |

| 7571AC | 46110 | 50 | 80 | 16 | 23.6 | 20.1 | 9200 | 11000 | 0.29 |

| 7011AC | 46111 | 55 | 90 | 18 | 31.1 | 26.3 | 8300 | 10000 | 0.42 |

| 7012AC | 46112 | 60 | 95 | 18 | 31.9 | 28.1 | 7700 | 9700 | 0.45 |

| 7013AC | 46113 | 65 | 100 | 18 | 33.7 | 31.4 | 7200 | 9000 | 0.47 |

| 7014AC | 46114 | 70 | 110 | 20 | 42.7 | 39.4 | 8300 | 0.66 | |

| 7015AC | 46115 | 75 | 115 | 20 | 43.6 | 41.7 | 6300 | 7800 | 0.69 |

| 7016AC | 46116 | 80 | 125 | 22 | 53.4 | 50.6 | 5800 | 7200 | 0.93 |

| 7017AC | 46117 | 85 | 130 | 22 | 54.6 | 53.7 | 5500 | 6800 | 0.97 |

| 7018AC | 46118 | 90 | 140 | 24 | 65.2 | 63.3 | 5100 | 6400 | 1.26 |

| 7019AC | 46119 | 95 | 145 | 24 | 66.6 | 67.1 | 4800 | 6000 | 1.32 |

| 7571AC | 46120 | 100 | 150 | 24 | 68.4 | 70.6 | 4700 | 5900 | 1.37 |

| 7571AC | 46121 | 105 | 160 | 26 | 79.8 | 81.9 | 4400 | 5500 | 1.73 |

| 7571AC | 46122 | 110 | 170 | 28 | 91.9 | 92.8 | 4200 | 5200 | 2.14 |

| 7571AC | 46124 | 120 | 180 | 28 | 96.6 | 103 | 3900 | 4900 | 2.27 |

| 7026AC | 46126 | 130 | 200 | 33 | 117 | 125 | 3500 | 4400 | 3.43 |

| 7571AC | 46128 | 140 | 210 | 33 | 120 | 133 | 3300 | 4100 | 3.64 |

| 7030AC | 46130 | 150 | 225 | 35 | 137 | 154 | 3000 | 3800 | 4.43 |

| 7032AC | 46132 | 160 | 240 | 38 | 5.02 | ||||

| 7034AC | 46134 | 170 | 260 | 42 | 186 | 214 | 2600 | 3200 | 7.56 |

| 7038AC | 46138 | 190 | 290 | 46 | 217 | 268 | 2300 | 2800 | 10.8 |

| 7040AC | 46140 | 200 | 310 | 51 | 244 | 309 | 2100 | 2600 | 12.7 |

| Bearing type | Boundary Dimensions(mm) | Load Rating (kn) |

Speed Rating(ipm) | Weight | |||||

| New Model | Old Model | d | D | B | Dymamic Cr | Static Cor | Grease lubrication |

Oil lubrication |

Weight (kg) |

| 7200AC | 46200 | 10 | 30 | 9 | 4.65 | 2.2 | 29000 | 37000 | 0.031 |

| 7201AC | 46201 | 12 | 32 | 10 | 7.45 | 3.65 | 27000 | 34000 | 0.038 |

| 7202AC | 46202 | 15 | 35 | 11 | 8.1 | 4.25 | 24000 | 29000 | 0.048 |

| 7203AC | 46203 | 17 | 40 | 12 | 10.2 | 5.5 | 21000 | 26000 | 0.07 |

| 7204AC | 46204 | 20 | 47 | 14 | 14.5 | 8.4 | 17000 | 22000 | 0.112 |

| 7205AC | 46205 | 25 | 52 | 15 | 15.3 | 9.5 | 15000 | 19000 | 0.135 |

| 7206AC | 46206 | 30 | 62 | 16 | 21.3 | 13.7 | 13000 | 16000 | 0.208 |

| 7207AC | 46207 | 35 | 72 | 17 | 28.1 | 18.6 | 11000 | 14000 | 0.295 |

| 7208AC | 46208 | 40 | 80 | 18 | 33.6 | 23.3 | 10000 | 12000 | 0.382 |

| 7209AC | 46209 | 45 | 85 | 19 | 37.7 | 26.6 | 9400 | 12000 | 0.43 |

| 7210AC | 46210 | 50 | 90 | 20 | 39.4 | 41.3 | 8500 | 11000 | 0.485 |

| 7211AC | 46211 | 55 | 700 | 21 | 48.7 | 37.1 | 7600 | 9500 | 0.635 |

| 7212AC | 46212 | 60 | 110 | 22 | 58.9 | 45.7 | 6900 | 8600 | 0.82 |

| 7213AC | 46213 | 65 | 120 | 23 | 67.3 | 54.2 | 6400 | 8000 | 1.02 |

| 7214AC | 46214 | 70 | 125 | 24 | 69.8 | 55.6 | 6100 | 7600 | 1.12 |

| 7215AC | 46215 | 75 | 130 | 25 | 79.2 | 65.2 | 5800 | 7200 | 1.23 |

| 7216AC | 46216 | 80 | 140 | 26 | 85.3 | 71.5 | 5400 | 6700 | 1.5 |

| 7217AC | 46217 | 85 | 150 | 28 | 98.6 | 83.6 | 5000 | 6300 | 1.87 |

| 7218AC | 46218 | 90 | 760 | 30 | 113 | 96.7 | 4700 | 5900 | 2.3 |

| 7219AC | 46219 | 95 | 770 | 32 | 122 | 103 | 4400 | 5500 | 2.78 |

| 7220AC | 46220 | 100 | 180 | 34 | 137 | 117 | 4100 | 5200 | 3.32 |

| 7221AC | 46221 | 105 | 190 | 36 | 149 | 132 | 3900 | 4900 | 3.95 |

| 7222AC | 46222 | 110 | 200 | 38 | 162 | 148 | 3700 | 4600 | 4.65 |

| 7224AC | 46224 | 130 | 215 | 40 | 174 | 166 | 3400 | 4300 | 5.49 |

| 7226AC | 46226 | 130 | 230 | 40 | 196 | 198 | 3200 | 4000 | 6.21 |

| 7228AC | 46228 | 140 | 250 | 42 | 218 | 234 | 2900 | 3600 | 7.76 |

| 7232AC | 46232 | 160 | 290 | 48 | 230 | 263 | 2500 | 3100 | 12.1 |

| 7234AC | 46234 | 170 | 370 | 52 | 272 | 331 | 2300 | 2800 | 15.1 |

| 7236AC | 46236 | 180 | 320 | 52 | 293 | 362 | 2200 | 2700 | 15.7 |

| 7240AC | 46240 | 200 | 360 | 58 | 324 | 432 | 1900 | 2400 | 22.4 |

| 7244AC | 46244 | 220 | 400 | 65 | 358 | 482 | 1100 | 1600 | 38.5 |

| Bearing type | Boundary Dimensions(mm) | Load Rating | Speed Rating(ipm) | Weight | |||||

| (kn) | |||||||||

| New Model | Old Model | d | D | B | Dymamic Cr | Static Cor | Grease | Oil | Weight |

| lubrication | lubrication | (kg) | |||||||

| 7300AC | 46300 | 10 | 35 | 11 | 8.5 | 3.75 | 27000 | 33000 | 0.054 |

| 7301AC | 46301 | 12 | 37 | 12 | 10.2 | 4.6 | 24000 | 31000 | 0.065 |

| 7302AC | 46302 | 15 | 42 | 13 | 12.5 | 6.45 | 20000 | 25000 | 0.088 |

| 7303AC | 46303 | 17 | 47 | 14 | 14.9 | 7.9 | 18000 | 23000 | 0.12 |

| 7304AC | 46304 | 20 | 52 | 15 | 17.4 | 9.4 | 17000 | 21000 | 0.15 |

| 7305AC | 46305 | 25 | 62 | 17 | 24.8 | 14.4 | 14000 | 17000 | 0.243 |

| 7306AC | 46306 | 30 | 72 | 19 | 30.1 | 18.9 | 12000 | 14000 | 0.362 |

| 7307AC | 46307 | 35 | 80 | 21 | 35.4 | 22 | 10000 | 13000 | 0.475 |

| 7308AC | 46308 | 40 | 90 | 23 | 43.2 | 27.4 | 9200 | 12000 | 0.657 |

| 7309AC | 46309 | 45 | 100 | 25 | 55.1 | 37.1 | 8200 | 10000 | 0.875 |

| 7310AC | 46310 | 50 | 170 | 27 | 70.1 | 48.7 | 7300 | 9100 | 1.14 |

| 7311AC | 46311 | 55 | 120 | 29 | 80.9 | 56.5 | 6700 | 8400 | 1.45 |

| 7312AC | 46312 | 60 | 130 | 31 | 92.5 | 65.6 | 6200 | 7700 | 1.81 |

| 7313AC | 46313 | 65 | 140 | 33 | 105 | 75.3 | 5800 | 7200 | 2.22 |

| 7314AC | 46314 | 70 | 150 | 35 | 118 | 85.8 | 5400 | 6700 | 2.7 |

| 7315AC | 46315 | 75 | 160 | 37 | 128 | 97 | 5000 | 6300 | 3.15 |

| 7316AC | 46316 | 80 | 170 | 39 | 139 | 109 | 4700 | 5900 | 3.85 |

| 7317AC | 46317 | 85 | 180 | 41 | 150 | 122 | 4400 | 5500 | 4.53 |

| 7318AC | 46318 | 90 | 190 | 43 | 161 | 135 | 4200 | 5200 | 5 |

| 7319AC | 46319 | 95 | 200 | 45 | 172 | 149 | 4000 | 4900 | 6.12 |

| 7320AC | 46320 | 100 | 215 | 47 | 184 | 161 | 3600 | 4600 | 7.53 |

| 7321AC | 46321 | 105 | 225 | 49 | 208 | 193 | 3500 | 4400 | 8.62 |

| 7322AC | 46322 | 110 | 240 | 50 | 232 | 226 | 3200 | 4000 | 10.7 |

| 7324AC | 46324 | 120 | 260 | 55 | 246 | 252 | 3000 | 3700 | 12.6 |

| 7326AC | 46326 | 130 | 280 | 58 | 301 | 329 | 2700 | 3400 | 15.4 |

| 7328AC | 46328 | 140 | 300 | 62 | 329 | 374 | 2500 | 3200 | 18.8 |

| 7330AC | 46330 | 150 | 320 | 65 | 348 | 414 | 2300 | 2900 | 22.4 |

| 7332AC | 46332 | 160 | 340 | 68 | 365 | 455 | 2200 | 2700 | 26.4 |

| 7334AC | 46334 | 170 | 360 | 72 | 389 | 485 | 2000 | 2500 | 31.2 |

| 7336AC | 46336 | 180 | 380 | 75 | 409 | 534 | 1900 | 2400 | 40 |

| 7338AC | 46338 | 190 | 400 | 78 | 450 | 598 | 1800 | 2200 | 45.5 |

| 7340AC | 46340 | 200 | 420 | 80 | 474 | 658 | 1700 | 2100 | 52 |

| 7406AC | 46406 | 30 | 90 | 23 | 0.960 | ||||

| 7407AC | 46407 | 35 | 100 | 25 | 1.140 | ||||

| 7408AC | 46408 | 40 | 110 | 27 | 1.400 | ||||

| 7409AC | 46409 | 45 | 120 | 29 | 1.800 | ||||

| 7410AC | 46410 | 50 | 130 | 31 | 2.250 | ||||

| 7411AC | 46411 | 55 | 140 | 33 | 2.750 | ||||

| 7412AC | 46412 | 60 | 150 | 35 | 3.400 | ||||

| 7413AC | 46413 | 65 | 160 | 37 | 4.200 | ||||

| 7414AC | 46414 | 70 | 180 | 42 | 5.800 | ||||

| 7415AC | 46415 | 75 | 190 | 45 | 7.000 | ||||

| 7416AC | 46416 | 80 | 200 | 48 | 8.000 | ||||

| Bearing type | Boundary Dimensions(mm) | Load Rating (kn) |

Speed Rating(ipm) | Weight | |||||

| New Model | Old Model | d | D | B | Dymamic Cr | Static Cor | Grease lubrication |

Oil lubrication |

Weight (kg) |

| 7204BTN | 66204 | 20 | 47 | 14 | 14.5 | 8.4 | 17000 | 22000 | 0.112 |

| 7205BTN | 66205 | 25 | 52 | 15 | 15.3 | 9.5 | 15000 | 19000 | 0.135 |

| 7206BTN | 66206 | 30 | 62 | 16 | 21.3 | 13.7 | 13000 | 16000 | 0.208 |

| 7207BTN | 66207 | 35 | 72 | 17 | 28.1 | 18.9 | 11000 | 14000 | 0.295 |

| 7208BTN | 66208 | 40 | 80 | 18 | 33.6 | 23.3 | 10000 | 12000 | 0.382 |

| 7209BTN | 66209 | 45 | 85 | 19 | 37.7 | 27 | 9400 | 12000 | 0.43 |

| 7210BTN | 66210 | 50 | 90 | 20 | 39.4 | 41.3 | 8500 | 11000 | 0.485 |

| 7211BTN | 66211 | 55 | 100 | 21 | 48.7 | 37.1 | 7600 | 9500 | 0.635 |

| 7212BTN | 66212 | 60 | 110 | 22 | 58.9 | 45.7 | 6900 | 8600 | 0.82 |

| 7213BTN | 66213 | 65 | 120 | 23 | 67.3 | 54.2 | 6400 | 8000 | 1.02 |

| 7214BTN | 66214 | 70 | 125 | 24 | 69.8 | 55.6 | 6100 | 7600 | 1.12 |

| 7215BTN | 66215 | 75 | 130 | 25 | 79.2 | 65.2 | 5800 | 7200 | 1.23 |

| 7216BTN | 66216 | 80 | 140 | 36 | 85.3 | 71.5 | 5400 | 6700 | 1.5 |

| 7217BTN | 66217 | 85 | 150 | 28 | 98.6 | 83.6 | 5000 | 6300 | 1.87 |

| 7218BTN | 66218 | 90 | 160 | 30 | 113 | 96.7 | 4700 | 5900 | 2.3 |

| 7219BTN | 66219 | 95 | 170 | 32 | 122 | 103 | 4400 | 5500 | 2.78 |

| 7220BTN | 66220 | 100 | 180 | 34 | 137 | 117 | 4700 | 5200 | 3.32 |

| 7221BTN | 66221 | 105 | 190 | 36 | 149 | 132 | 3900 | 4900 | 3.95 |

| 7222BTN | 66222 | 110 | 200 | 38 | 162 | 148 | 3700 | 4600 | 4.65 |

| 7224BTN | 66224 | 120 | 215 | 40 | 174 | 166 | 3400 | 4300 | 5.49 |

| 7226BTN | 66226 | 130 | 230 | 40 | 196 | 198 | 3200 | 4000 | 6.21 |

| 7228BTN | 66228 | 140 | 250 | 42 | 218 | 234 | 2900 | 3600 | 7.76 |

| Bearing type | Boundary Dimensions(mm) | Load Rating | Speed Rating(ipm) | Weight | |||||

| (kn) | |||||||||

| New Model | Old Model | d | D | B | Dymamic Cr | Static Cor | Grease | Oil | Weight |

| lubrication | lubrication | (kg) | |||||||

| 7303BTN | 66303 | 17 | 47 | 14 | 14.9 | 7.9 | 18000 | 23000 | 0.12 |

| 7304BTN | 66304 | 20 | 52 | 15 | 17.4 | 9.4 | 17000 | 21000 | 0.15 |

| 7305BTN | 66305 | 25 | 62 | 17 | 24.8 | 14.4 | 14000 | 77000 | 0.243 |

| 7306BTN | 66306 | 30 | 72 | 19 | 30.1 | 19 | 12000 | 14000 | 0.362 |

| 7307BTN | 66307 | 35 | 80 | 21 | 35.4 | 22 | 10000 | 13000 | 0.475 |

| 7308BTN | 66308 | 40 | 90 | 23 | 43.2 | 27.4 | 9200 | 12000 | 0.657 |

| 7309BTN | 66309 | 45 | 100 | 25 | 55.1 | 37.1 | 8200 | 10000 | 0.875 |

| 7310BTN | 66310 | 50 | 110 | 27 | 70.1 | 48.1 | 7300 | 9100 | 1.14 |

| 7311BTN | 66311 | 55 | 120 | 29 | 80.9 | 56.5 | 6700 | 8400 | 1.45 |

| 7312BTN | 66312 | 60 | 130 | 31 | 92.5 | 65.6 | 6200 | 7700 | 1.81 |

| 7313BTN | 66313 | 65 | 140 | 33 | 105 | 75.3 | 5800 | 7200 | 2.22 |

| 7314BTN | 66314 | 70 | 150 | 35 | 118 | 85.8 | 5400 | 6700 | 2.7 |

| 7315BTN | 66315 | 75 | 160 | 37 | 128 | 97 | 5000 | 6300 | 3.15 |

| 7316BTN | 66316 | 80 | 170 | 39 | 139 | 109 | 4700 | 5900 | 3.85 |

| 7317BTN | 66317 | 85 | 180 | 41 | 150 | 122 | 4400 | 5500 | 4.53 |

| 7318BTN | 66318 | 90 | 190 | 43 | 161 | 135 | 4200 | 5200 | 5.3 |

| 7319BTN | 66319 | 95 | 200 | 45 | 172 | 149 | 4000 | 4900 | 6.12 |

| 7320BTN | 66320 | 100 | 215 | 47 | 184 | 161 | 3600 | 4600 | 7.53 |

| 7321BTN | 66321 | 105 | 225 | 49 | 208 | 193 | 3500 | 4400 | 8.62 |

| 7322BTN | 66322 | 110 | 240 | 50 | 232 | 226 | 3200 | 4000 | 10.1 |

| 7324BTN | 66324 | 120 | 260 | 55 | 246 | 252 | 3000 | 3700 | 12.6 |

Company Profile

HangZhou solarich machinery Co., Ltd. is a professional manufacturer of bearings, specialized in the research and development of high precision angular contact ball bearings, double row angular contact ball bearings, ball screw bearings.

Our company in accordance with ISO international standards and GB national standards organization production, adhere to the “integrity, dedication, innovation, beyond” spirit of enterprise, “one heart, consistent, first-class” business philosophy, determined to choose reasonable quality axis for customers.

Products are widely used in: machine tool, precision machinery spindle, aviation, gas turbine, high frequency motor, high speed motor, air compressor, oil pump, printing machinery and other fields. The company promises to reasonable commodity prices, fast logistics delivery, quality service, and strong technical force, won the support and trust of customers, and truly realize the CZPT situation between the company and customers. Quality and development, is our pursuit.

Solutions

Single row angular contact ball bearings: machine tool spindle, high frequency motor, gas turbine, centrifugal separator, small car front wheel, differential pinion shaft, booster pump, drilling platform, food machinery, dividing head, repair welding machine, low noise type cooling tower, electromechanical equipment, painting equipment, machine slot plate, arc welding machine

Double row angular contact ball bearings: oil pump, Roots blower, air compressor, various transmission, fuel injection pump, printing machinery, planetary reducer, extraction equipment, cycloidal reducer, food packaging machinery, electric welding machine, electric soldering iron, square box, gravity spray gun, wire stripping machine, half shaft, inspection and analysis equipment, fine chemical machinery.

Our Advantages

1. World-Class Bearing: We provide our customers with all types of indigenous bearing with world-class quality.

2. OEM or Non-Stand Bearings: Any requirement for Nonstandard bearings is Easily Fulfilled by us due to its vast knowledge and links in the industry.

3. Genuine products With Excellent Quality: The company has always proved the 100% quality products it provides with genuine intent.

4. After Sales Service and Technical Assistance: The company provides after-sales service and technical assistance as per the customer’s requirements and needs.

5. Quick Delivery: The company provides just-in-time delivery with its streamlined supply chain.

Packaging & Shipping

FAQ

Q: Are you trading company or manufacturer?

A: We are bearing manufacturer.

Q: How do you control quality of bearing?

A: All products and services passed ISO9001-2008 Quality Certificate.

Q: What is the MOQ?

A: It depends on the bearing type. You can send inquiry or send e-mail for more information.

Q: How about the package?

A: Industrial packing in general condition (Plastic tube+ carton+ pallet). Accept design package when OEM.

Q: How long is the delivery time?

A: The lead time for sample orders is 3-5 days, for bulk orders is 5-15 days., depends on the model and quantity.

Q: How about the shipping?

A: We can arrange the shipment or you may have the forwarder.

Q: Is sample avaiable?

A: Yes, sample order is acceptable.

Q: Can we use our own LOGO or design on bearings?

A: Yes. OEM is acceptable. We can design the bearing with your requirements and use your own LOGO and package design.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 25° |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Samples: |

US$ 2/Piece

1 Piece(Min.Order) | Order Sample |

|---|

| Customization: |

Available

| Customized Request |

|---|

.shipping-cost-tm .tm-status-off{background: none;padding:0;color: #1470cc}

| Shipping Cost:

Estimated freight per unit. |

about shipping cost and estimated delivery time. |

|---|

| Payment Method: |

|

|---|---|

|

Initial Payment Full Payment |

| Currency: | US$ |

|---|

| Return&refunds: | You can apply for a refund up to 30 days after receipt of the products. |

|---|

What Factors should be Considered when Selecting a Tapered Roller Bearing for a Specific Application?

Choosing the right tapered roller bearing for a specific application involves considering various factors to ensure optimal performance and reliability. Here are the key factors to consider:

- Load Requirements:

Assess the types and magnitudes of both radial and axial loads the bearing will experience. Choose a tapered roller bearing with a load capacity that comfortably exceeds the expected loads to prevent premature wear or failure.

- Speed:

Determine the required rotational speed of the bearing. High-speed applications may require bearings designed for reduced friction and heat generation to maintain efficiency and avoid overheating.

- Precision and Tolerance:

Consider the level of precision required for the application. Tapered roller bearings are available in different precision classes, such as ABEC (Annular Bearing Engineering Committee) grades, which impact factors like smoothness and accuracy of rotation.

- Mounting and Installation:

Assess the available space for mounting the bearing and consider the ease of installation. Bearings with adjustable clearance or preload might be advantageous for fine-tuning the bearing’s internal play.

- Temperature and Environment:

Take into account the operating temperature range and environmental conditions of the application. Extreme temperatures or corrosive environments may require specific bearing materials or coatings.

- Lubrication:

Choose an appropriate lubricant based on the application’s speed, temperature, and load conditions. Proper lubrication ensures smooth operation, reduces friction, and prolongs the bearing’s lifespan.

- Cost and Budget:

Consider the budget allocated for bearings. High-precision or specialized bearings may come at a higher cost, but their performance benefits can outweigh the initial investment over the bearing’s service life.

- Application Type:

Identify the specific industry and application in which the bearing will be used. Tapered roller bearings are employed in various sectors, including automotive, heavy machinery, aerospace, and more.

- Expected Lifespan:

Estimate the required bearing lifespan for the application. Factors such as load, speed, and maintenance practices can impact the bearing’s longevity.

- Bearing Size and Design:

Choose a bearing size that fits within the application’s space constraints while providing the necessary load capacity. The design, including the number and arrangement of rollers, can influence load distribution and performance.

- Maintenance Requirements:

Consider the maintenance schedule and accessibility for bearing inspection and replacement. Bearings in applications with limited maintenance intervals may require enhanced durability.

In conclusion, selecting a tapered roller bearing for a specific application involves assessing load requirements, speed, precision, mounting, temperature, lubrication, cost, application type, expected lifespan, bearing size, and maintenance considerations. Careful evaluation of these factors ensures that the chosen bearing meets the demands of the application while providing reliable performance and longevity.

What Advantages do Tapered Roller Bearings Offer Compared to Other Bearing Types?

Tapered roller bearings offer several advantages that make them a preferred choice in various applications compared to other bearing types. These advantages stem from their unique design and capabilities. Here’s a look at the benefits of tapered roller bearings:

- High Load-Carrying Capacity:

Tapered roller bearings can handle both radial and axial loads simultaneously, making them suitable for applications with combined loads. Their conical geometry allows for effective load distribution, enabling them to support heavy loads without premature wear.

- Efficient Axial Load Handling:

Tapered roller bearings excel at managing axial (thrust) loads in one direction. This capability is crucial in applications where axial loads are present, such as automotive transmissions or industrial machinery.

- Reduced Friction and Heat Generation:

The conical shape of the rollers and the matching raceways result in point contact, reducing friction and minimizing heat generation. This efficiency contributes to improved overall performance and energy savings.

- Adjustable Clearance and Preload:

Tapered roller bearings often allow for adjustable internal clearance or preload. This feature enables fine-tuning of the bearing’s play, optimizing performance and extending the bearing’s lifespan.

- High Precision:

Tapered roller bearings are available in various precision classes to meet different application requirements. Their precision makes them suitable for applications demanding accurate motion control and positioning.

- Versatility:

Tapered roller bearings are used in a wide range of industries and applications, from automotive and heavy machinery to aerospace and industrial equipment. Their ability to handle diverse loads and conditions contributes to their versatility.

- Durability:

Tapered roller bearings are designed to withstand shocks and impacts, making them suitable for applications with dynamic loads or vibrations. Their robust construction contributes to their overall durability.

- High-Speed Capability:

Tapered roller bearings can operate at high speeds due to their efficient contact geometry and reduced friction. This makes them suitable for applications requiring rapid rotation.

- Cost-Effectiveness:

While the initial cost may vary, tapered roller bearings are often cost-effective due to their long service life and ability to handle heavy loads. Their durability can lead to reduced maintenance and replacement costs over time.

- Compatibility with Combined Loads:

Tapered roller bearings are well-suited for applications where radial and axial loads occur simultaneously, eliminating the need for multiple bearing types and simplifying design and installation.

In summary, tapered roller bearings offer a combination of load-carrying capacity, efficiency, adjustability, precision, and versatility that sets them apart from other bearing types. Their ability to handle a variety of loads and conditions makes them an advantageous choice in numerous industrial applications.

What Advantages do Tapered Roller Bearings Offer Compared to Other Bearing Types?

Tapered roller bearings offer several advantages that make them a preferred choice in various applications compared to other bearing types. These advantages stem from their unique design and capabilities. Here’s a look at the benefits of tapered roller bearings:

- High Load-Carrying Capacity:

Tapered roller bearings can handle both radial and axial loads simultaneously, making them suitable for applications with combined loads. Their conical geometry allows for effective load distribution, enabling them to support heavy loads without premature wear.

- Efficient Axial Load Handling:

Tapered roller bearings excel at managing axial (thrust) loads in one direction. This capability is crucial in applications where axial loads are present, such as automotive transmissions or industrial machinery.

- Reduced Friction and Heat Generation:

The conical shape of the rollers and the matching raceways result in point contact, reducing friction and minimizing heat generation. This efficiency contributes to improved overall performance and energy savings.

- Adjustable Clearance and Preload:

Tapered roller bearings often allow for adjustable internal clearance or preload. This feature enables fine-tuning of the bearing’s play, optimizing performance and extending the bearing’s lifespan.

- High Precision:

Tapered roller bearings are available in various precision classes to meet different application requirements. Their precision makes them suitable for applications demanding accurate motion control and positioning.

- Versatility:

Tapered roller bearings are used in a wide range of industries and applications, from automotive and heavy machinery to aerospace and industrial equipment. Their ability to handle diverse loads and conditions contributes to their versatility.

- Durability:

Tapered roller bearings are designed to withstand shocks and impacts, making them suitable for applications with dynamic loads or vibrations. Their robust construction contributes to their overall durability.

- High-Speed Capability:

Tapered roller bearings can operate at high speeds due to their efficient contact geometry and reduced friction. This makes them suitable for applications requiring rapid rotation.

- Cost-Effectiveness:

While the initial cost may vary, tapered roller bearings are often cost-effective due to their long service life and ability to handle heavy loads. Their durability can lead to reduced maintenance and replacement costs over time.

- Compatibility with Combined Loads:

Tapered roller bearings are well-suited for applications where radial and axial loads occur simultaneously, eliminating the need for multiple bearing types and simplifying design and installation.

In summary, tapered roller bearings offer a combination of load-carrying capacity, efficiency, adjustability, precision, and versatility that sets them apart from other bearing types. Their ability to handle a variety of loads and conditions makes them an advantageous choice in numerous industrial applications.

editor by CX 2024-05-09

China supplier 71920C/AC/B High-Speed Angular Contact Ball Bearings 100X140X20mm P6/P5/P4/P2 Used in Machine Tool Spindles High Frequency Motors, Gas Turbines 718/719/70/72 ball bearing

Product Description

Product description

Model: Angular contact ball bearings (71920C)

Brand: AUTO

Series: Angular contact ball bearings, single row, no seals

Shape size

d: 100

D: 140

B: 20

| 718 Series Angular Contact Bearings |

| 719 Series Angular Contact Bearings |

| H719 Series Angular Contact Bearings |

| 70 Series Angular Contact Bearings |

| H70 Series Angular Contact Bearings |

| B70 Series Angular Contact Bearings |

| 72 Series Angular Contact Bearings |

Company

HangZhou Auto Bearing Co., Ltd. is located in the industrial park of HangZhou,which is 1 of the 4 great ancient capitals of China.Our company is the member of China Bearing Industry Association,cooperating with State Quality Supervision and Testing Center for bearing.Our company is a professional bearing manufacturer which integrated with research ,development and marketing services.

Our major products include deep groove ball bearing, spherical roller bearing, slewing ring, crossed roller bearing and other all kinds of high precision bearings.Our products are widely applied to motor industry,mining metallurgy,wind power generation,petroleum drilling,automobile and motorcycle etc..

Our company not only possesses advanced bearing manufacturing equipments and international first-class measuring instruments, but also has strong strength of manufacturing, inspecting and testing the high precision and reliability bearings.Each process is in strict accordance with the ISO9001 quality management system,which effectively guarantees the precise of products and stability of the performance. AUTO bearings are mainly exported to the United states,South Korea,Europe,etc., which have reached the high level of foreign similar products.

The soul of our business culture is [Detail makes competitive, innovation makes first-class”.We believe the production and management philosophy of [quality wins ,casting competitive products”.The company adheres to the zero-defect quality management for meeting customer requirements.

Packing

A. plastic box & outer carton & pallets

B. plastic bag & box & carton & pallet

C. tube package & middle box & carton & pallet

D. Depends on your needs

Delivery

A. Most orders will be shipped within 3-5 days of payment being received.

B. Samples will be shipped by cov2urier as FedEx,UPS,DHL,etc.

Thank you very much for taking time to view our company’s website. If you are interested in this product, please feel free to contact us. We are always here.

/* January 22, 2571 19:08:37 */!function(){function s(e,r){var a,o={};try{e&&e.split(“,”).forEach(function(e,t){e&&(a=e.match(/(.*?):(.*)$/))&&1

| Contact Angle: | 15°/25°/40° |

|---|---|

| Aligning: | Non-Aligning Bearing |

| Separated: | Unseparated |

| Rows Number: | Single |

| Load Direction: | Axial Bearing |

| Material: | Bearing Steel |

| Customization: |

Available

| Customized Request |

|---|

Can rolling contact bearings be customized or modified to meet specific industrial requirements?

Yes, rolling contact bearings can be customized or modified to meet specific industrial requirements. Bearing manufacturers offer a range of customization options to tailor bearings to unique application needs. These customizations can include modifications in design, materials, dimensions, and performance characteristics. Here’s a detailed explanation of the customization possibilities for rolling contact bearings:

- Design Modifications:

Bearing manufacturers can modify the design of rolling contact bearings to suit specific industrial requirements. This can involve altering the internal geometry, such as ball or roller profiles, cage design, or the number and arrangement of rolling elements. Design modifications aim to optimize the bearing’s load-carrying capacity, speed capability, or resistance to specific operating conditions. By customizing the design, manufacturers can address unique challenges and enhance the performance of rolling contact bearings in specific applications.

- Material Selection: